Preparation method of copper crystal whiskers

A copper whisker and copper powder technology, which is applied in the field of copper whisker preparation, can solve the problems of slow whisker growth and few copper whisker preparation methods, and achieve the effects of high repeatability, enhanced performance, or expanded performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

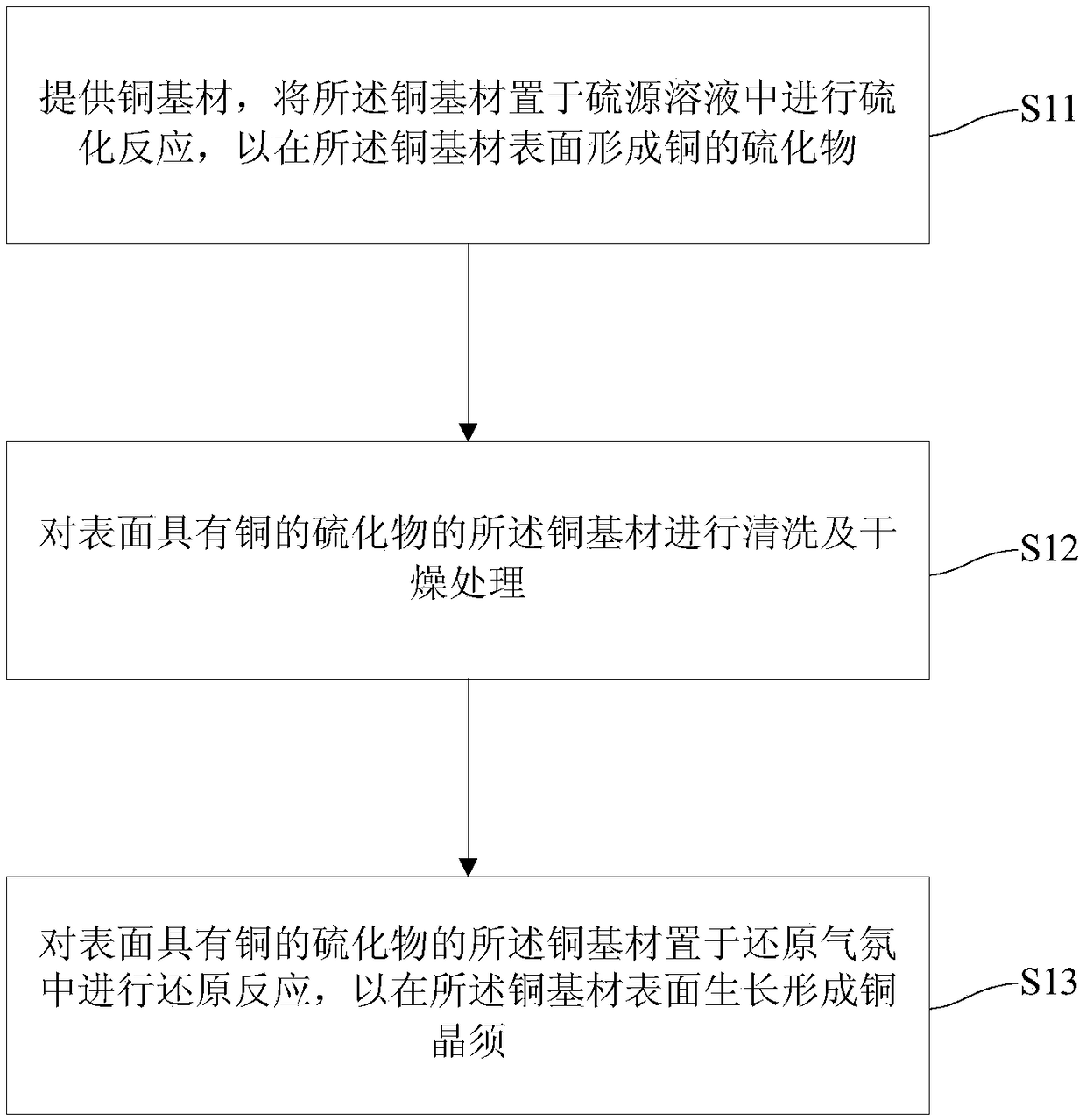

[0032] Such as figure 1 As shown, the present embodiment provides a kind of preparation method of copper whisker, and described preparation method comprises:

[0033] Such as figure 1 As shown, first perform step 1) S11, provide a copper substrate, place the copper substrate in a sulfur source solution for a vulcanization reaction, to form copper sulfide on the surface of the copper substrate;

[0034] The copper substrate includes one of the group consisting of copper wire, copper foam, copper foil, copper plate, copper ingot and copper powder.

[0035] The sulfur source solution contains pure thiourea SC(NH 2 ) 2 One of the mixed solutions of solution and thiourea. In this embodiment, the sulfur source solution may be a pure thiourea solution.

[0036] The material of the copper substrate includes simple copper and copper alloy. For example, the copper alloy includes one of the group consisting of red copper, brass, bronze and cupronickel. Preferably, the copper substra...

Embodiment 1

[0048] The present embodiment provides a kind of method for preparing copper whisker on copper wire, specifically comprises:

[0049] 1) Put a 200-micron diameter copper wire into a 5g / L thiourea solution, pour the whole into a reaction kettle for 24 hours at 150°C and vulcanize for 24 hours; take out the copper wire after cooling down, wash it with deionized water, and then dry it.

[0050] 2) Put the dry surface-vulcanized copper wire into the heating area of the quartz tube furnace, vacuumize, feed 200 sccm hydrogen to normal pressure, open the gas outlet of the cavity, and continue to feed 200 sccm hydrogen to maintain the inside of the quartz cavity Atmospheric pressure.

[0051] 3) Heat to 500°C and maintain for 4h.

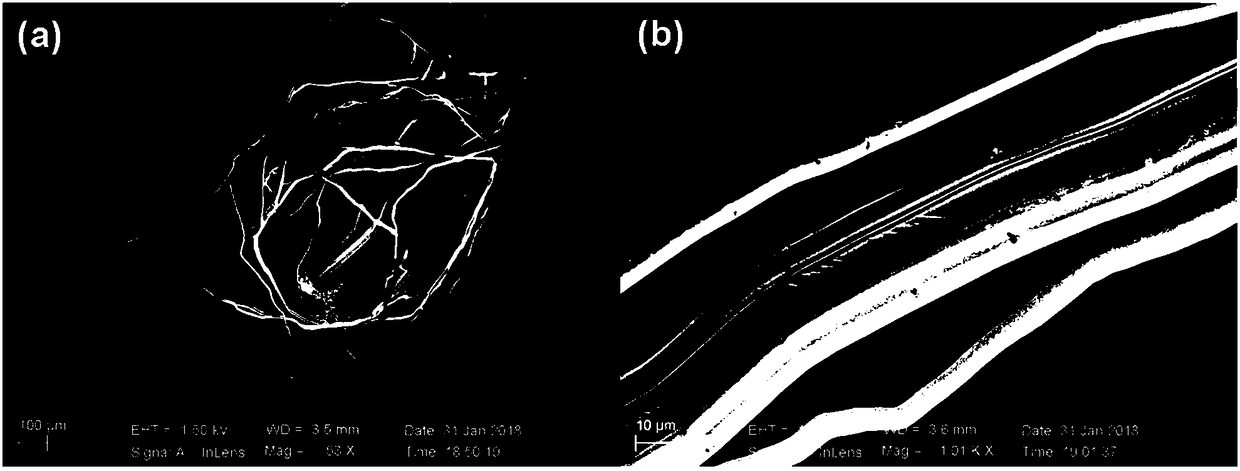

[0052] 4) Keep the atmosphere unchanged, and the copper wire is covered with whiskers when it reaches room temperature, such as figure 2 As shown in a, the arrows in the figure show copper wires (thickened after vulcanization), and the small-diameter wir...

Embodiment 2

[0054] The present embodiment provides a kind of method for preparing copper whisker on copper powder, comprising:

[0055] 1) Put the copper powder with a diameter of 200 mesh into 5g / L thiourea solution, pour the whole into the reaction kettle for 24 hours at 150°C and vulcanize for 24 hours; after cooling down, take out the copper powder, filter it, wash it with deionized water, and then dry it.

[0056] 2) Put the dry copper powder vulcanized on the surface into the heating area of the quartz tube furnace, evacuate, pass in 200sccm hydrogen to normal pressure, open the gas outlet of the cavity, and continue to pass in 200sccm hydrogen to maintain the inside of the quartz cavity Atmospheric pressure.

[0057] 3) Heat to 500°C and maintain for 4h.

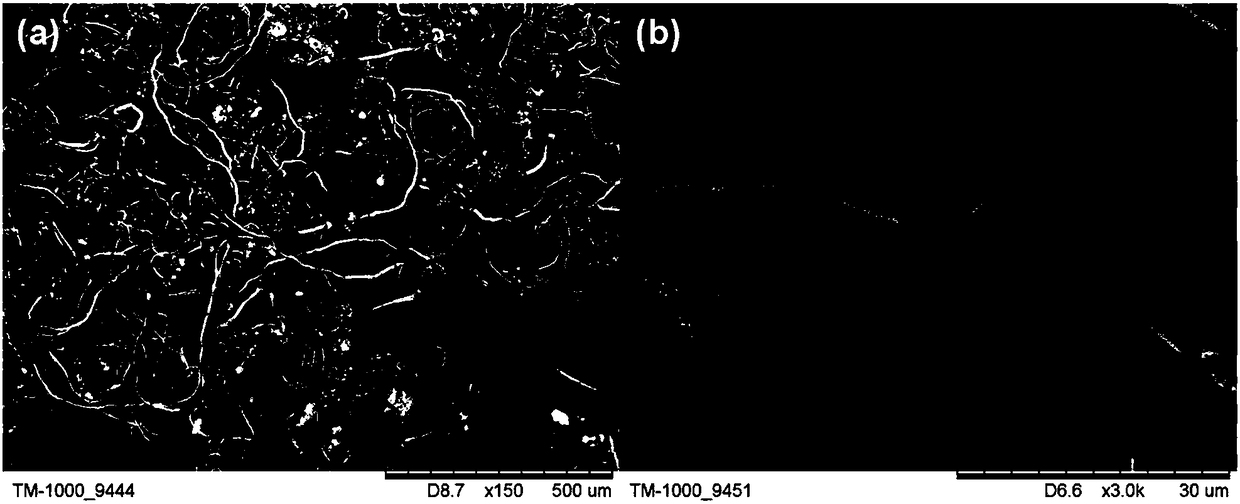

[0058] 4) Keep the atmosphere constant, and get to room temperature to obtain copper whiskers, such as image 3 As shown in a, it can be clearly seen that many copper whiskers over 1mm are grouped together. image 3 b is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com