Light splitting manufacturing process for five-junction solar cell system

A solar cell and manufacturing method technology, applied in the photovoltaic field of solar energy utilization, can solve the problems such as the photovoltaic technology can not achieve the best matching, the material growth yield is low, the solar cell is difficult, etc., so as to improve the photoelectric conversion efficiency, achieve absorption, reduce The effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and easy to understand, the following special embodiments of the present invention are described in detail as follows:

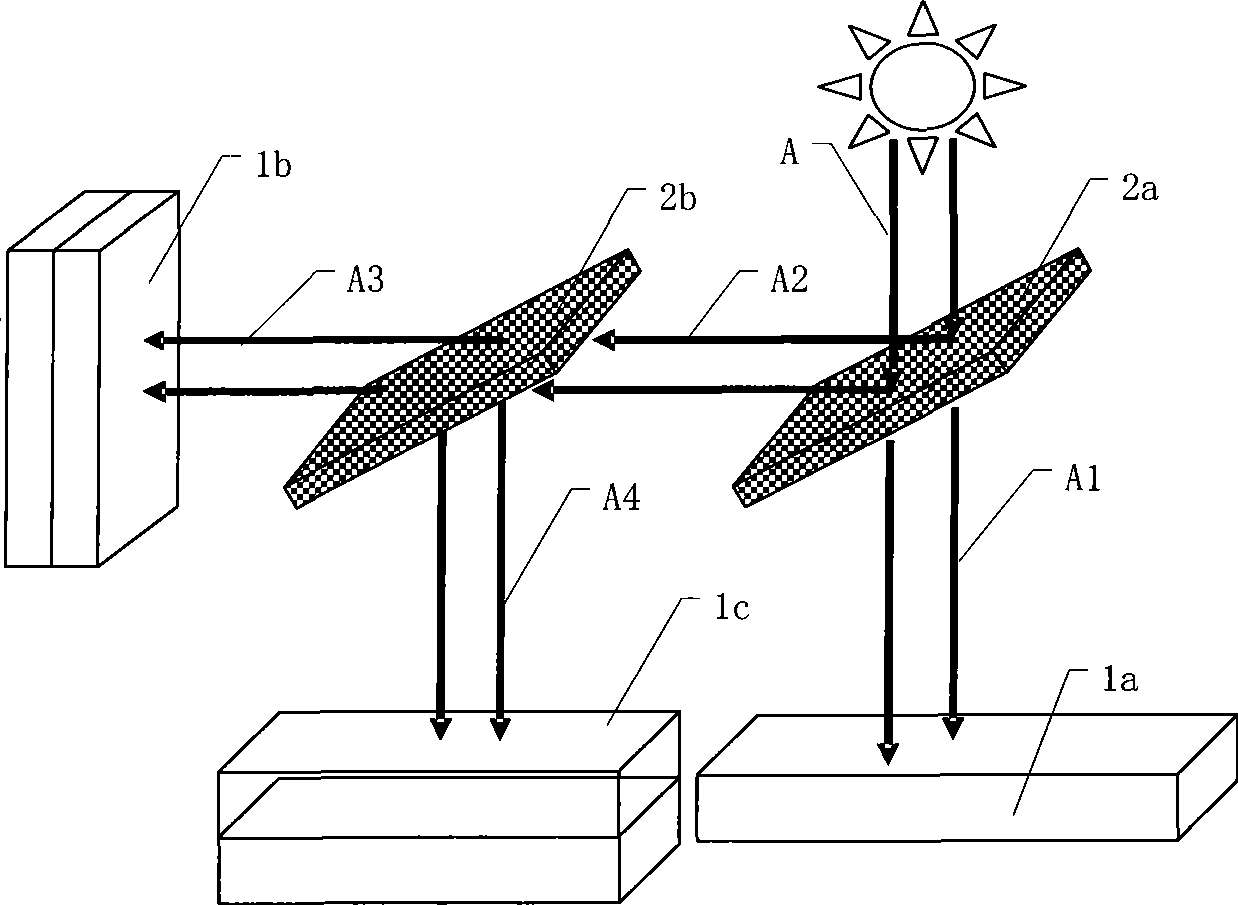

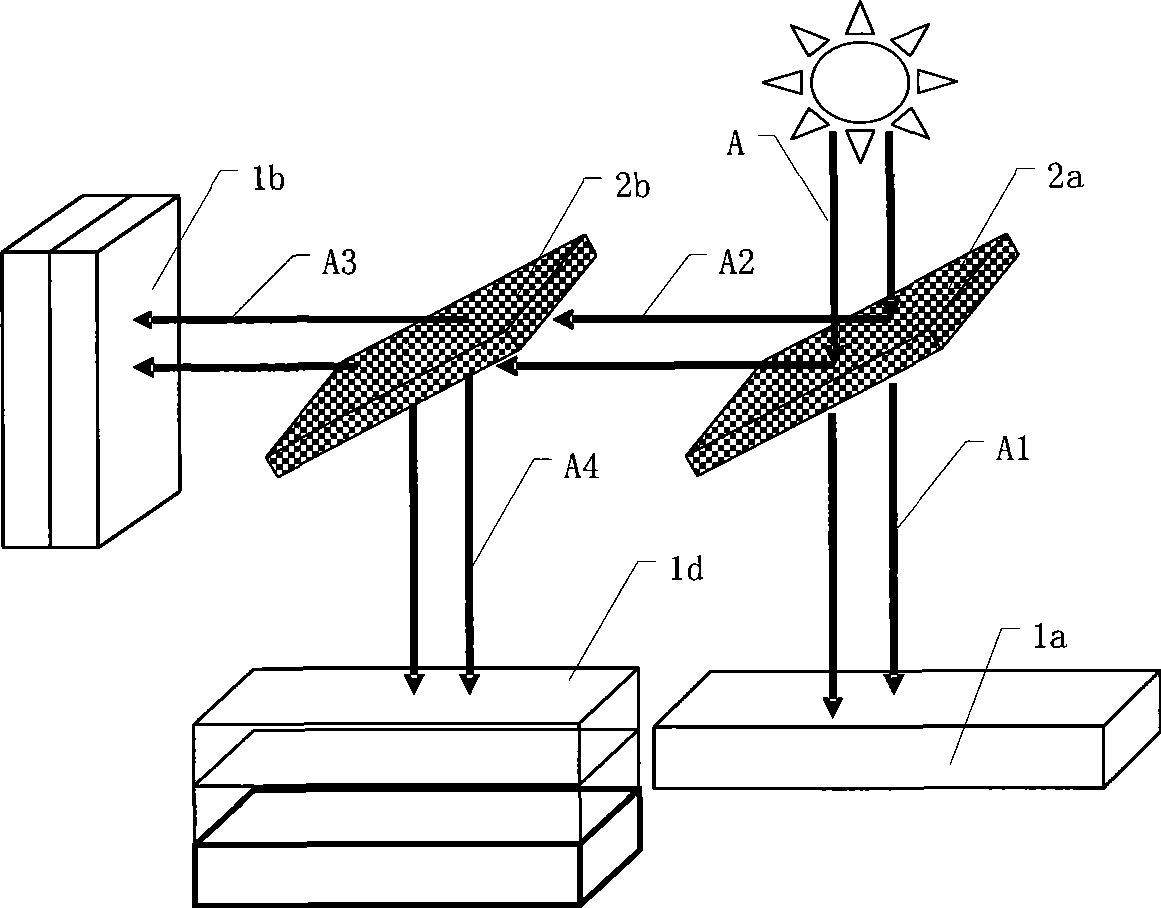

[0022] Such as figure 1 and figure 2 A schematic diagram of the structure of the light-splitting multi-junction solar cell system of the present invention shown. It can be clearly seen from the drawings that the multi-junction solar cell system structure includes: a cell panel body, an epitaxial wafer and its semiconductor substrate, and a light splitting device. In particular, the solar cell system is a two-plus-two-plus-one junction configuration, that is, the double junction In 0.3 Ga 0.7 As / Ge or InGaAsP / In grown on InP substrate 0.58 Ga 0.42 As cascaded solar cell 1c or 1d, double-junction InGaP / GaAs cascaded solar cell b and single-junction InGaN or ZnSe solar cell 1a are electrically connected. As the core technology of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com