Germanium nanopoint/silicon nanowire array structure thin film and preparation thereof

A silicon nanowire array, silicon nanowire technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of few layers of germanium nanodots, small diameter of germanium nanodots, low production cost, etc. Good, low cost of production equipment, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings;

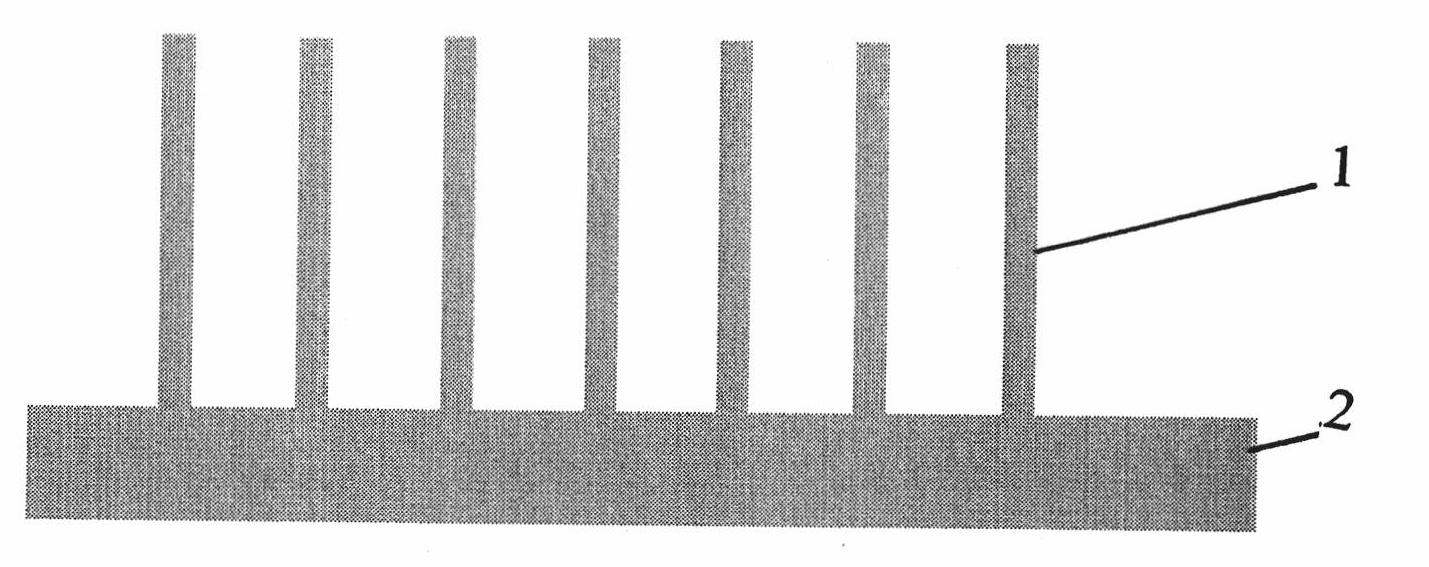

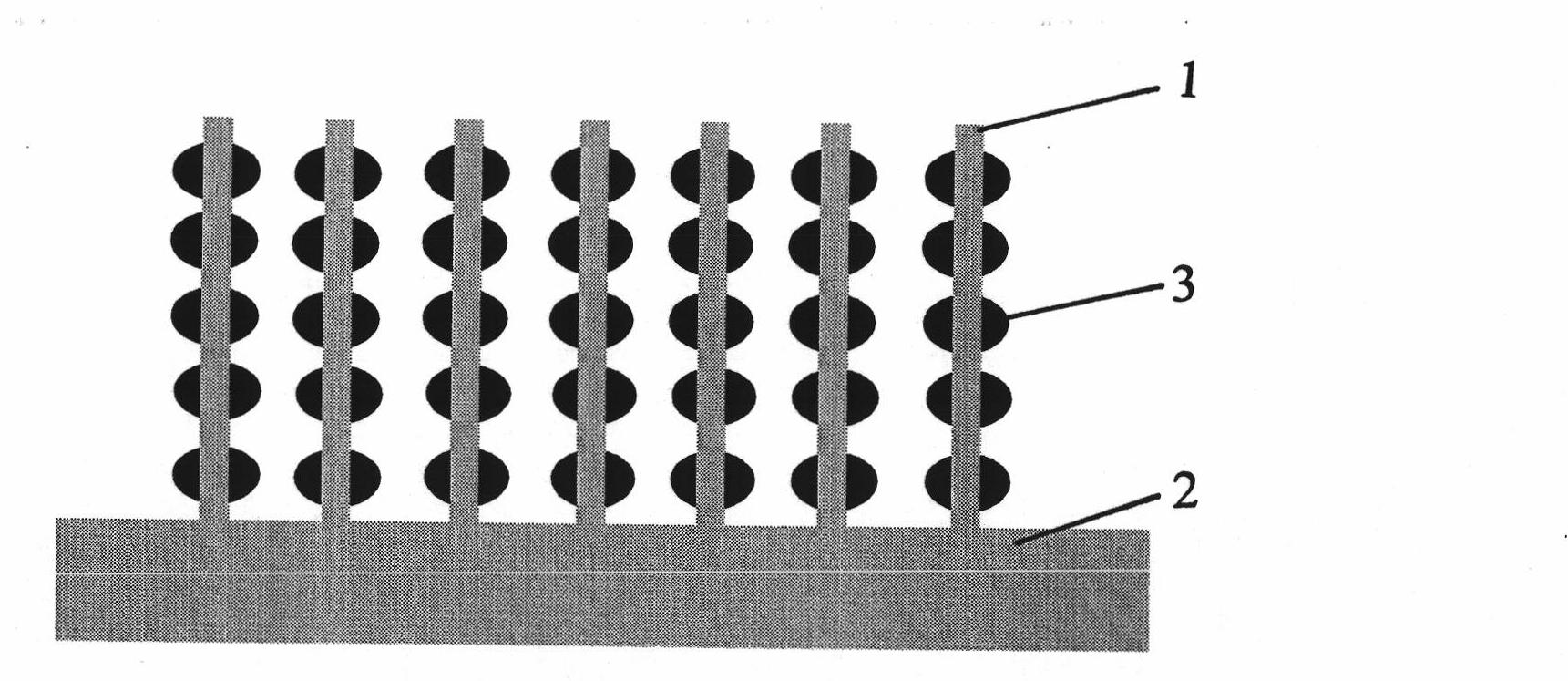

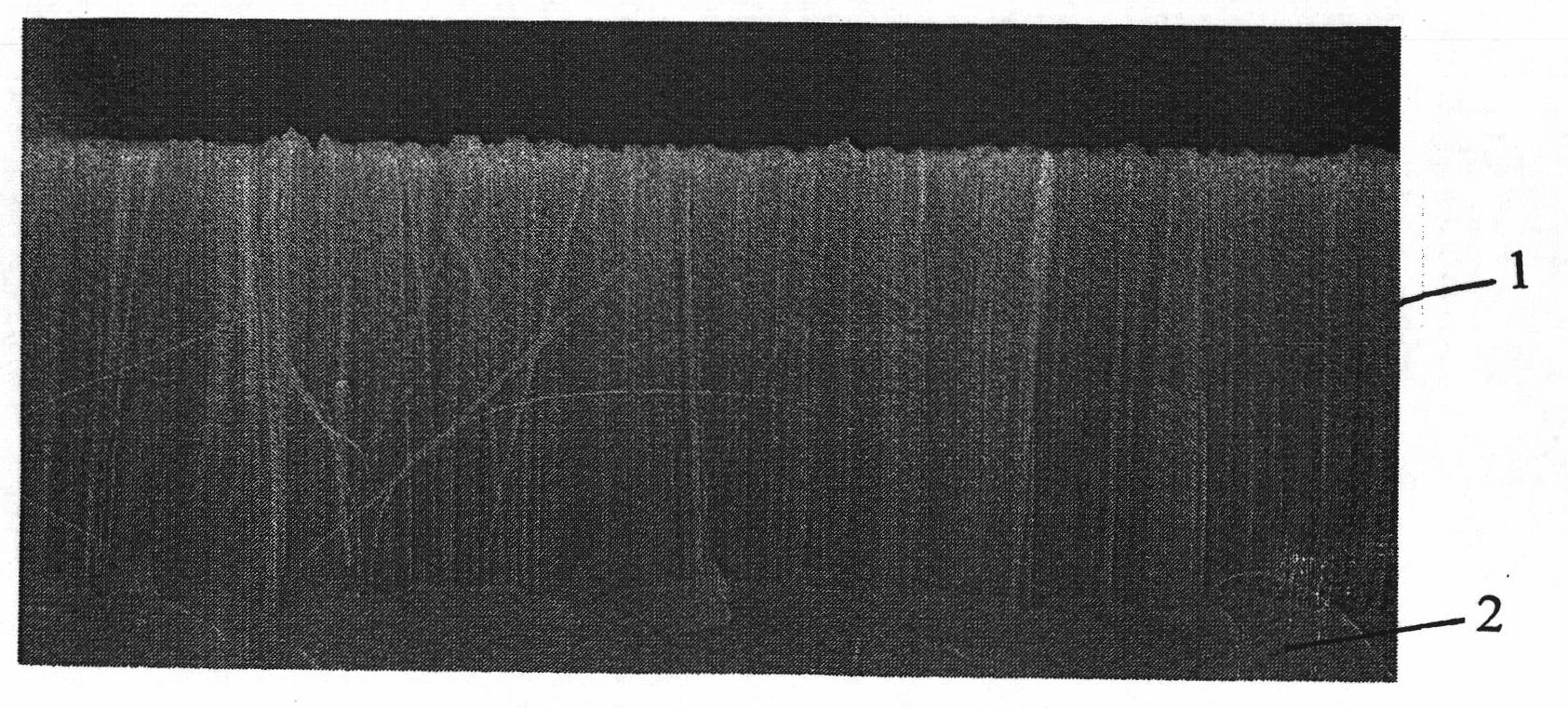

[0020] The germanium nano-dot / silicon nano-wire array structure thin film of the present invention is mainly composed of a silicon nano-wire array and germanium nano-dots, and the germanium nano-dots 3 are distributed on the silicon nano-wires 1 of the silicon nano-wire array.

[0021] Various techniques can be adopted for preparing the silicon nanowire array substrate in the present invention. For example, the method of utilizing chemical etching specifically includes: preparing a substrate, which can be a single crystal P-type silicon wafer, or a single crystal N-type silicon wafer, or a polycrystalline silicon wafer; After cleaning, silver is deposited on the surface of the substrate. The specific deposition method can be by evaporation, sputtering or chemical methods; substrate.

[0022] The solution etching method of the silicon na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com