Preparation of nonaqueous synthesized lead stearate

The technology of lead stearate and dibasic lead stearate is applied in the fields of plastics and rubber additives, which can solve the problems of high labor intensity, large alkali and acid consumption, high energy consumption, etc., so as to reduce the labor intensity of workers. , the effect of reducing labor intensity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

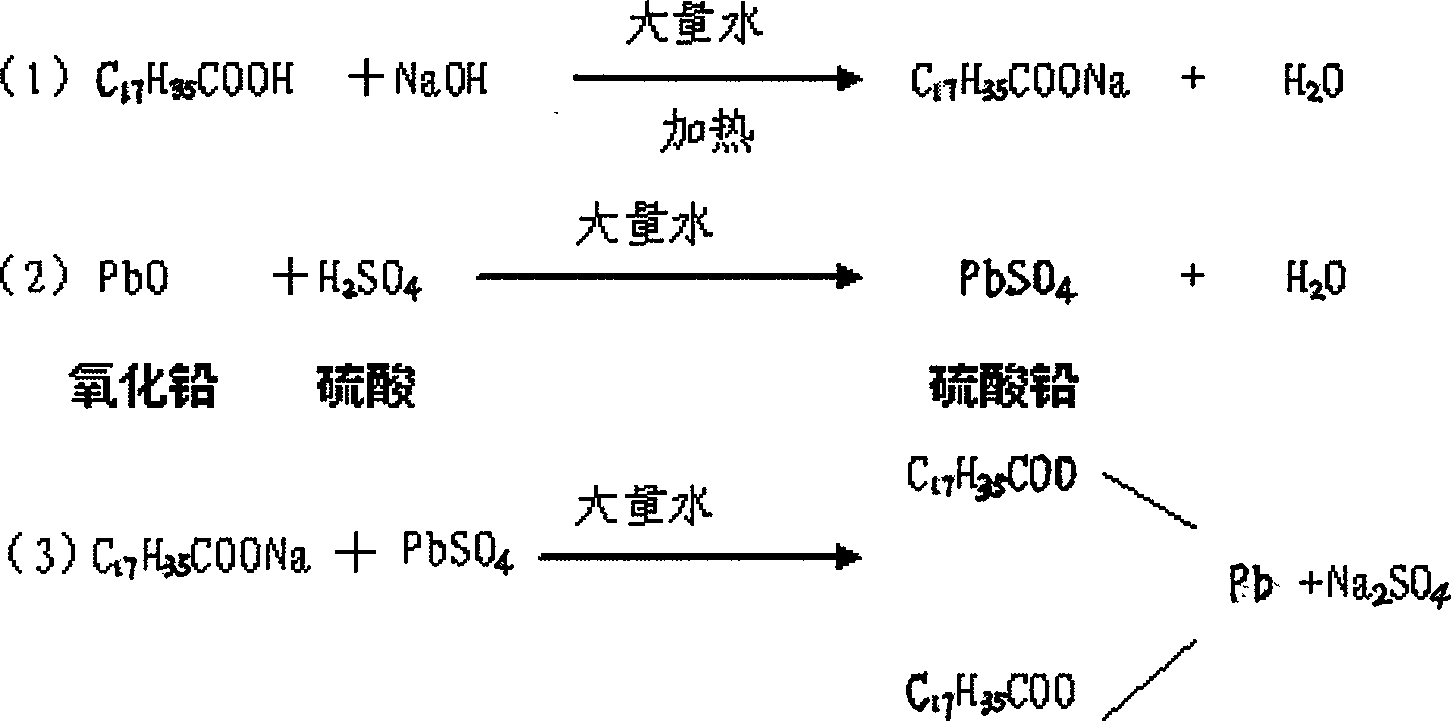

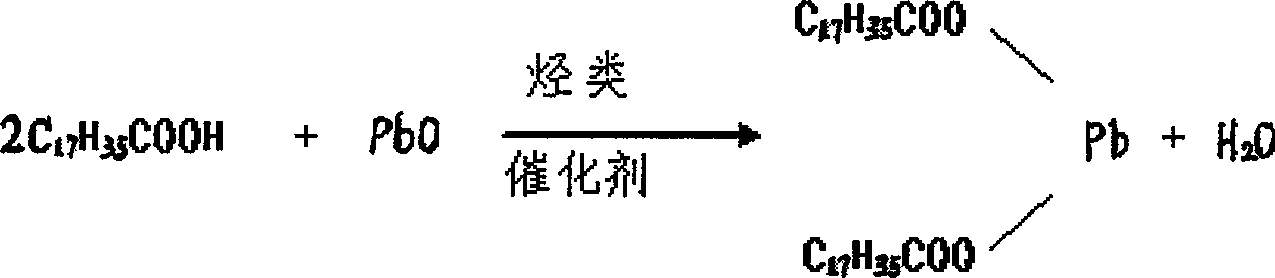

Method used

Image

Examples

Embodiment 1

[0020] Formula: (unit: kg)

[0021] Stearic acid 75

[0022] Lead oxide 75

[0023] Ethylene bis stearamide 3

[0024] Paraffin 95

[0025] Weigh the above reactants respectively, add them into the Xingxing stirring reactor, and react for 2 hours under stirring, the reaction temperature is 70-80°C, and discharge the materials to obtain lead n-stearate and dibasic lead stearate. Mixture, the yield is ninety-nine percent of the theoretical value. The product contains no water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com