Organic modification method for attapulgite stone and uses of organic modified attapulgite stone

A technology of attapulgite and attapulgite clay, applied in chemical instruments and methods, inorganic chemistry, adsorption water/sewage treatment, etc., can solve problems such as increased industrial costs, complicated experimental operations, complex systems, etc., and achieves organophilicity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

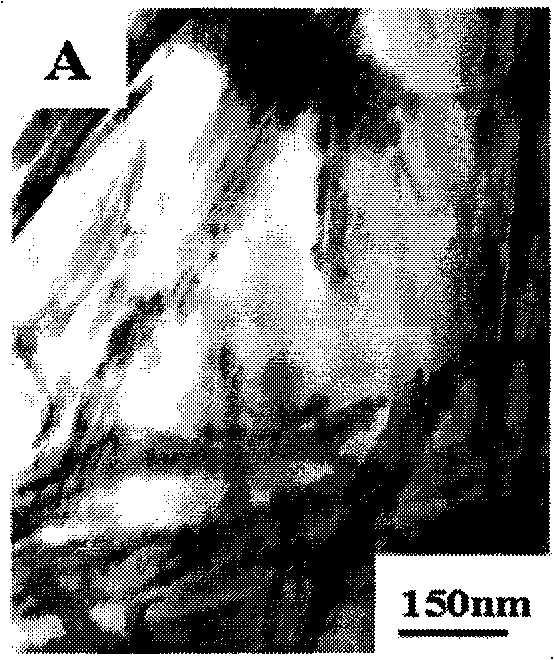

[0023] Take 1 g of attapulgite clay and 1 g of glucose, mix them in 100 ml of distilled water, and ultrasonically disperse for 30 minutes, while adjusting the pH of the solution to 9 with NaOH. The uniformly dispersed mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, and the filling rate was maintained at 80%. The reaction temperature was 180°C, and the carbonization was carried out for 48 hours. After the reaction, the product was naturally cooled to room temperature, the collected product was centrifuged, washed alternately with water and ethanol, and dried at 100°C to obtain a black product. Elemental analysis gave a carbon content of 14%. Infrared analysis shows that attapulgite / carbon composites contain organic functional groups such as C-H, such as figure 2 In the curve a, the product morphology is characterized by TEM (such as Figure 1A shown), it was found that amorphous carbon was supported on attapulgite.

Embodiment 2

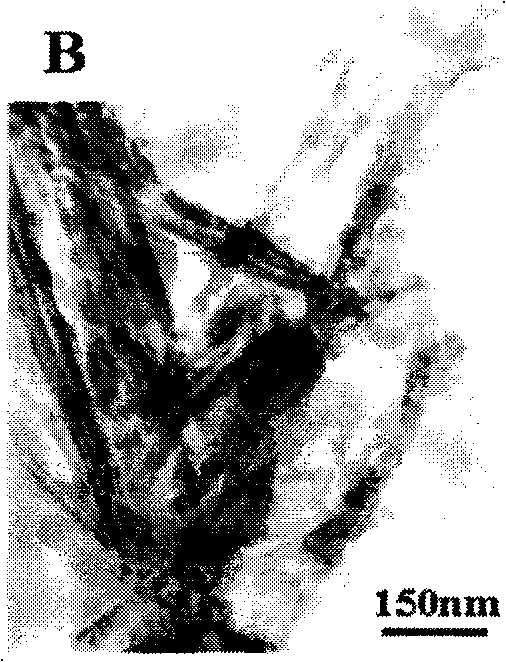

[0025] Take 1 g of attapulgite clay and 2 g of glucose, mix them in 100 ml of distilled water, and disperse them ultrasonically, while adjusting the pH of the solution to 7 with NaOH. The uniformly dispersed mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, and the filling rate was kept at 75%. The reaction temperature was 160°C, and the carbonization was carried out for 12 hours. After the reaction, the product was naturally cooled to room temperature, collected and centrifuged, washed alternately with water and ethanol, and dried at 80°C to obtain a tan product. Infrared analysis shows that attapulgite / carbon composites contain organic functional groups such as C-H, such as figure 2 Middle curve b. Product morphology was characterized by TEM (such as Figure 1B shown), it was found that amorphous carbon was supported on attapulgite.

Embodiment 3

[0027] Take 1 g of attapulgite clay and 4 g of glucose, mix them in 100 ml of distilled water, and disperse them ultrasonically. The initial pH value of the solution was 6.8, and the uniformly dispersed mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, and the filling rate was maintained at 80%. The reaction temperature was 180°C, and the carbonization was carried out for 48 hours. After the reaction, the product was naturally cooled to room temperature, collected and centrifuged, washed alternately with water and ethanol, and dried at 90°C to obtain a black product. Elemental analysis gave a carbon content of 21%. Infrared analysis shows that attapulgite / carbon composites contain organic functional groups such as C-H, such as figure 2 Shown in curve c. The product morphology is characterized by SEM as Figure 1C As shown, it was found that amorphous carbon was supported on attapulgite.

[0028] figure 2 The middle curve d is the infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com