Method for preparing block polyester polyether copolymer from polyester prepolymer and polyether prepolymer

A technology of polyester polyether copolymerization and polyether prepolymer, which is applied in the field of preparation of block polyester polyether copolymers, can solve the problems of poor thermal stability and low melting point, and achieve low price, low polymerization temperature and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

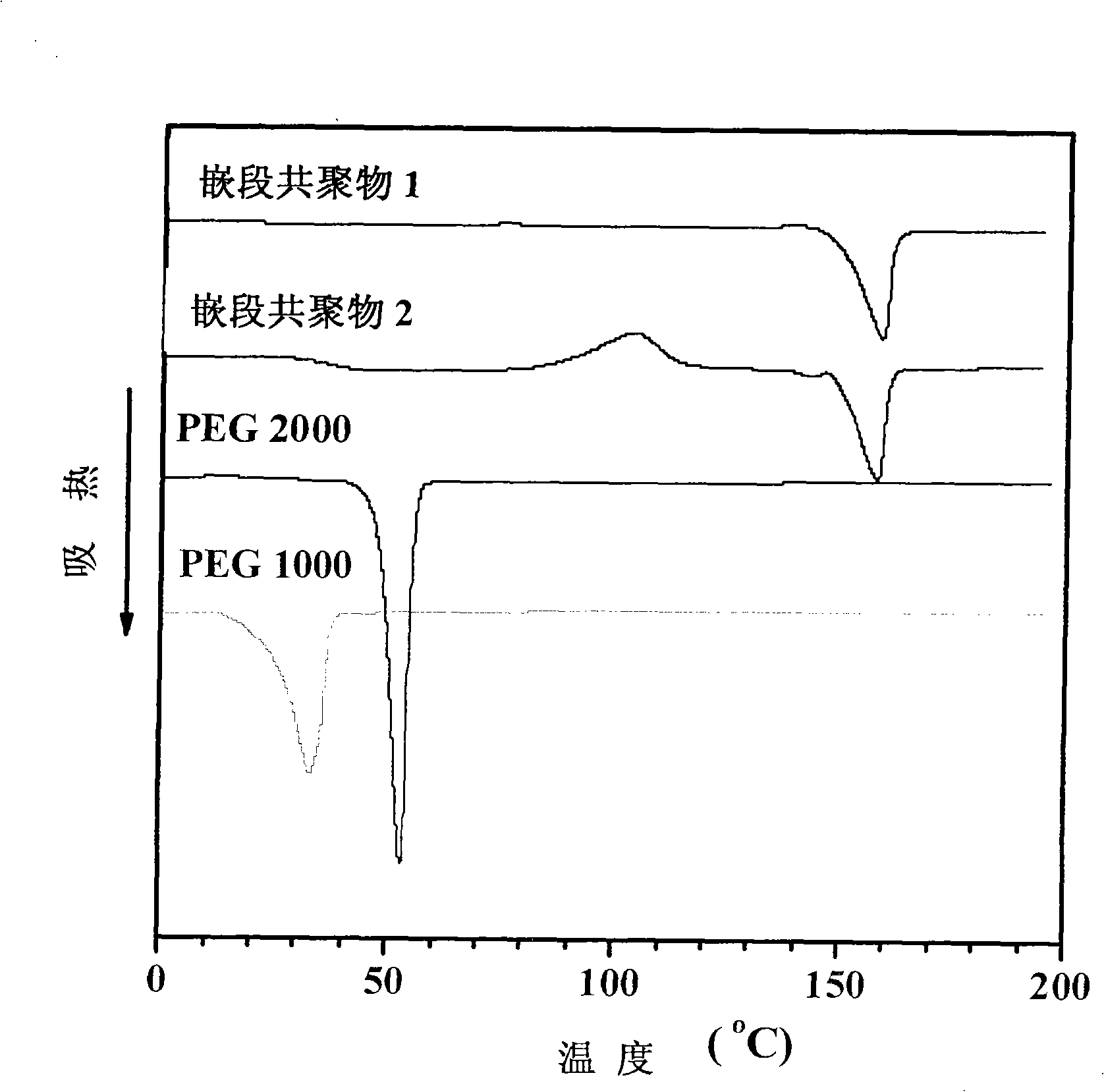

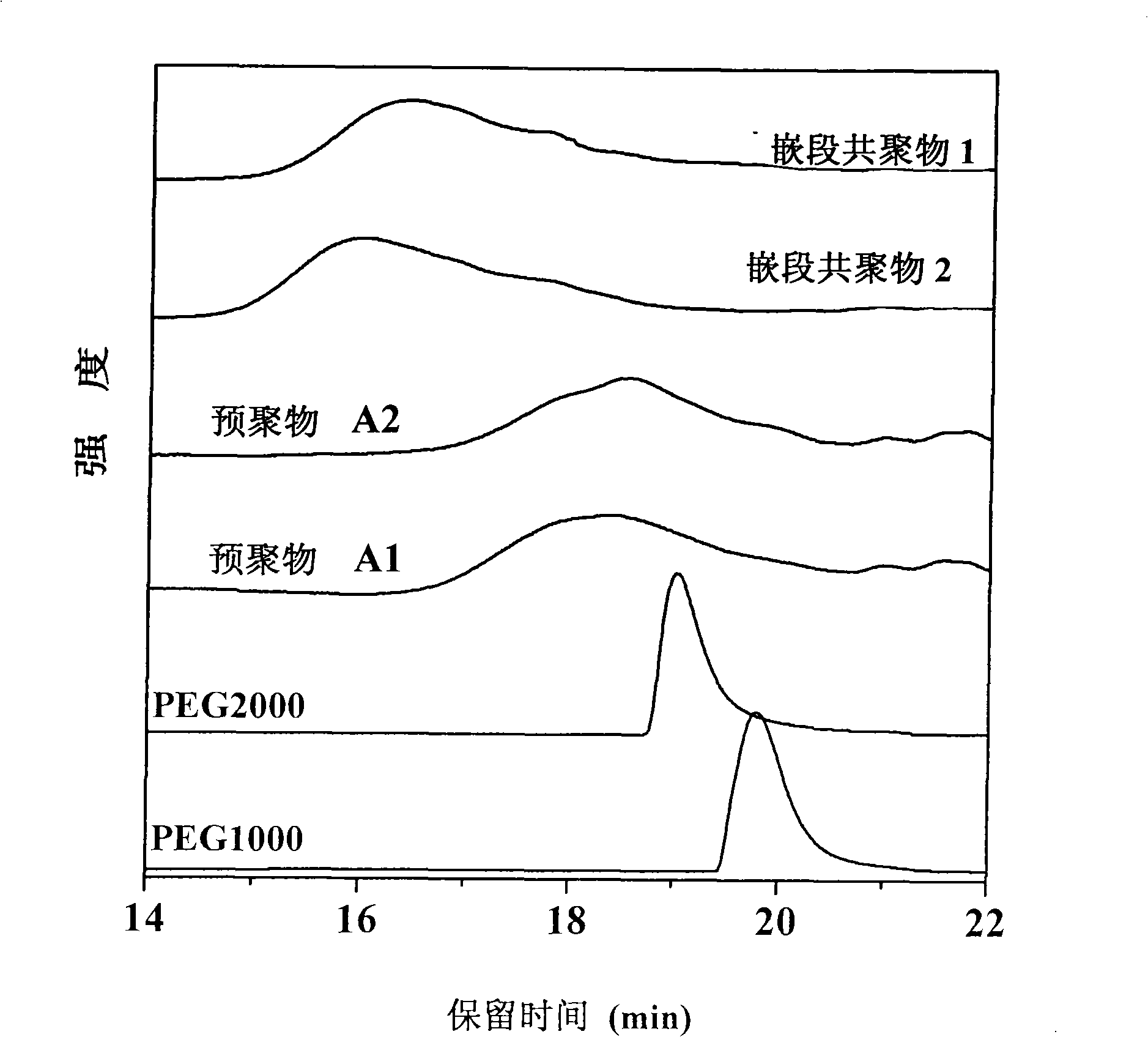

[0070] Add 140g of crystalline polyester prepolymer A1, 7g of polyether prepolymer B2, 0.45g of stannous acetate, 0.6g of p-toluenesulfonic acid and 0.83g of succinic acid into a 500ml three-necked bottle, connect mechanical stirring, nitrogen and vacuum lines. After the system was replaced with nitrogen three times, under the flow of ultra-pure nitrogen, the temperature was raised to 165° C. and after the prepolymer was completely melted, stirring was started at 100 rpm for 10 minutes. After cooling down to 100°C, the mixture was crystallized at 100°C for 2 hours. Take out and crush the mixture, take 50g of 100-250um powder and put it into a vacuum oven, depressurize to 200Pa, perform solid-state polymerization at 145°C for 10 hours, and obtain 45g of block copolymer 1 (DSC and GPC results see attached figure 1 and 2 ). As determined by GPC, the weight average molecular weight Mw is 45000.

Embodiment 2

[0072] Add 160g of crystalline polyester prepolymer A2, 40g of polyether prepolymer B1, and 5.09g of succinic acid into a 500ml three-necked bottle, and connect the mechanical stirring, nitrogen and vacuum pipelines. After the system was replaced with nitrogen three times, under the flow of ultra-pure nitrogen, the temperature was raised to 170° C. and after the prepolymer was completely melted, stirring was started at 100 rpm for 10 minutes. After cooling down to 100°C, the mixture was crystallized at 100°C for 2 hours. Take out and crush the mixture, take 50g of 100-250um powder and put it into a vacuum oven, depressurize to 200Pa, perform solid phase polymerization at 148°C for 10 hours to obtain 46g of block copolymer 2 (see DSC and GPC results in attached figure 1 and 2 ). As determined by GPC, the weight average molecular weight Mw is 85000.

Embodiment 3

[0074] Add 120g of crystalline polyester prepolymer A4, 80g of polyether prepolymer B3, and 4.000g of succinic anhydride into a 500ml three-necked bottle, and connect the mechanical stirring, nitrogen and vacuum pipelines. After the system was replaced with nitrogen three times, under the flow of ultra-pure nitrogen, the temperature was raised to 220° C. and after the prepolymer was completely melted, stirring was started at 100 rpm for 10 minutes. After cooling down to 160°C, the mixture was crystallized at 160°C for 2 hours. Take out and crush the mixture, take 50g of 100-250um powder and put it into a vacuum oven, reduce the pressure to 200Pa, perform solid phase polymerization at 200°C for 16 hours to obtain 46g of block copolymer. As determined by GPC, the weight average molecular weight Mw is 53000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com