Novel method for producing iron ore sintering mine additive

A production method and sintering technology, applied in the production field of iron ore sintering additives, can solve the problems of low sintering rate and strength, high production cost, poor sintering granulation effect, etc., so as to improve ironmaking production efficiency, Low production cost and improved granulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

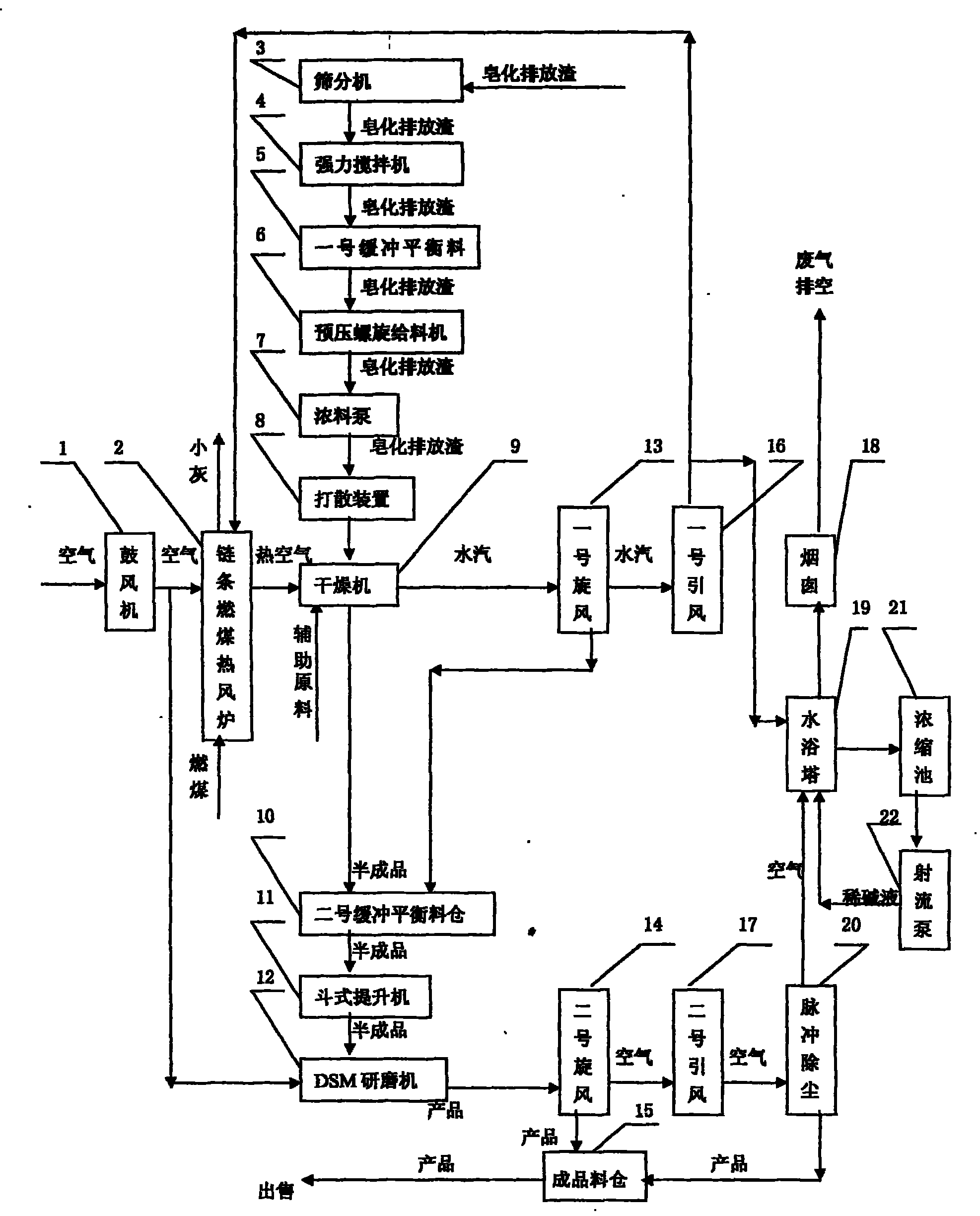

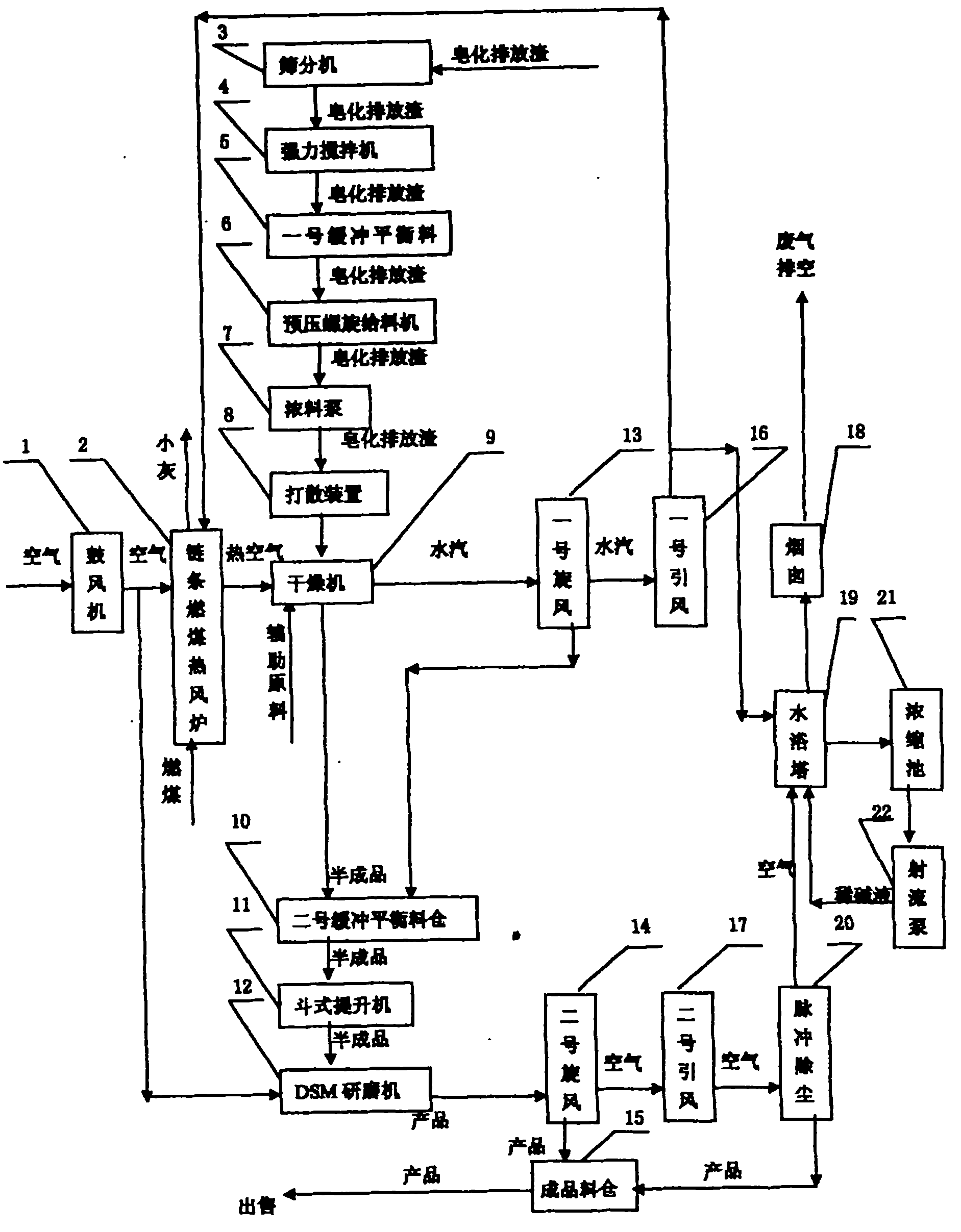

[0020] The production method of the iron ore sinter additive of the present invention is realized in this way, and will be described in detail below in conjunction with the accompanying drawings.

[0021] See figure 1 , the screening machine 3 is connected with the powerful mixer 4, the powerful mixer 4 is connected with the No. The pump 7 is connected, the concentrated material pump 7 is connected with the dispersing device 8, the dispersing device 8 is connected with the material inlet of the WJG type forced fluidized scraper dryer 9, and the WJG type forced fluidized scraper dryer The hot air inlet of the dryer 9 is connected to the outlet of the chain coal-fired hot blast stove 2, and the inlet of the chain coal-fired hot blast stove 2 is connected to the outlet of the blower 1; the WJG rotor type forced fluidization scraping wall dryer 9 material outlet is balanced with the No. 2 buffer The material inlet of the silo 10 is connected, the material outlet of the second buf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com