Method for purifying methyl isobutyl ketone exhaust gas in vacuum system using waste compressor oil

A technology of methyl isobutyl ketone and air compressor oil, applied in chemical instruments and methods, separation methods, organic chemistry and other directions, can solve problems such as environmental pollution, achieve high removal efficiency, reduce treatment costs, and save water resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

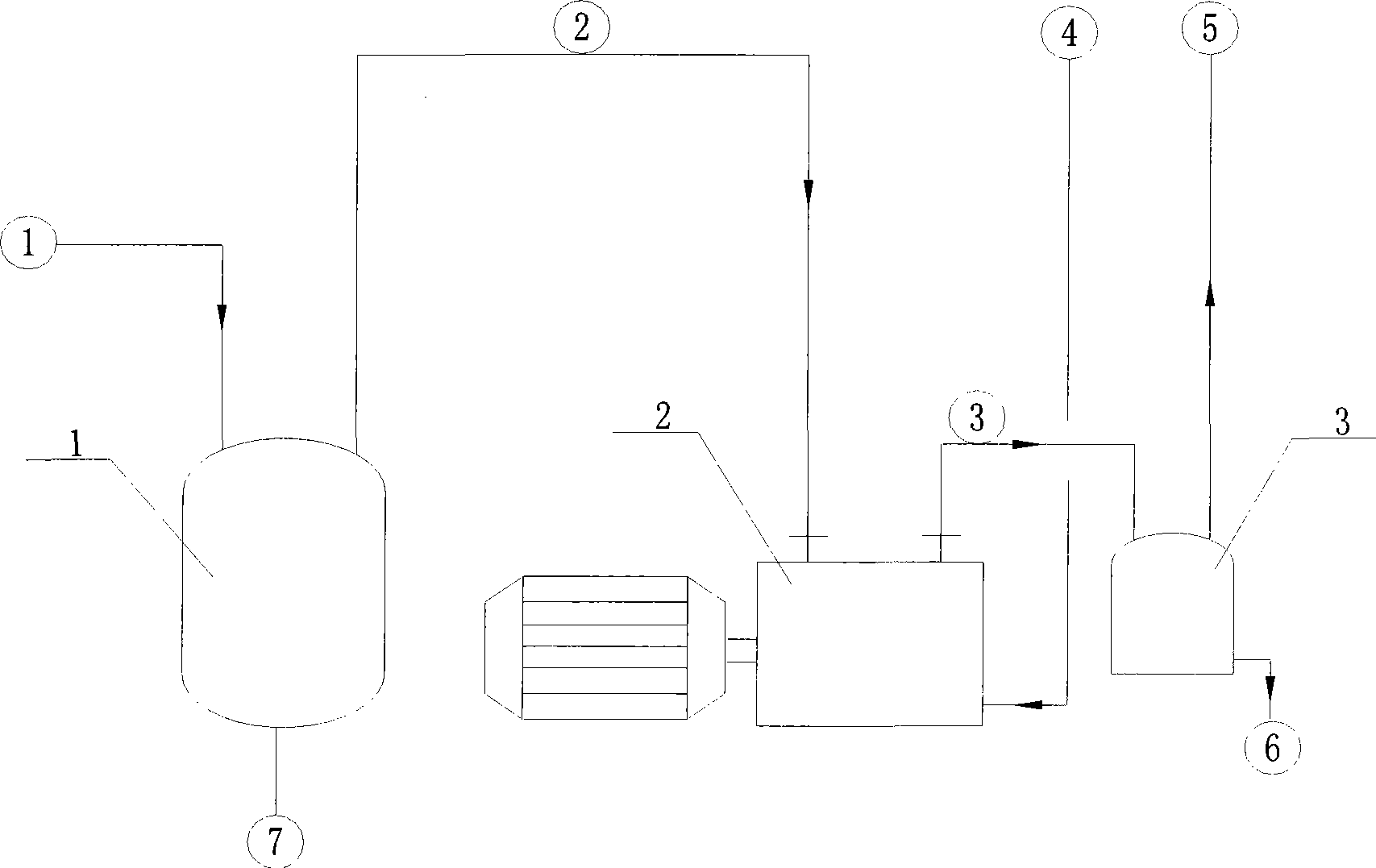

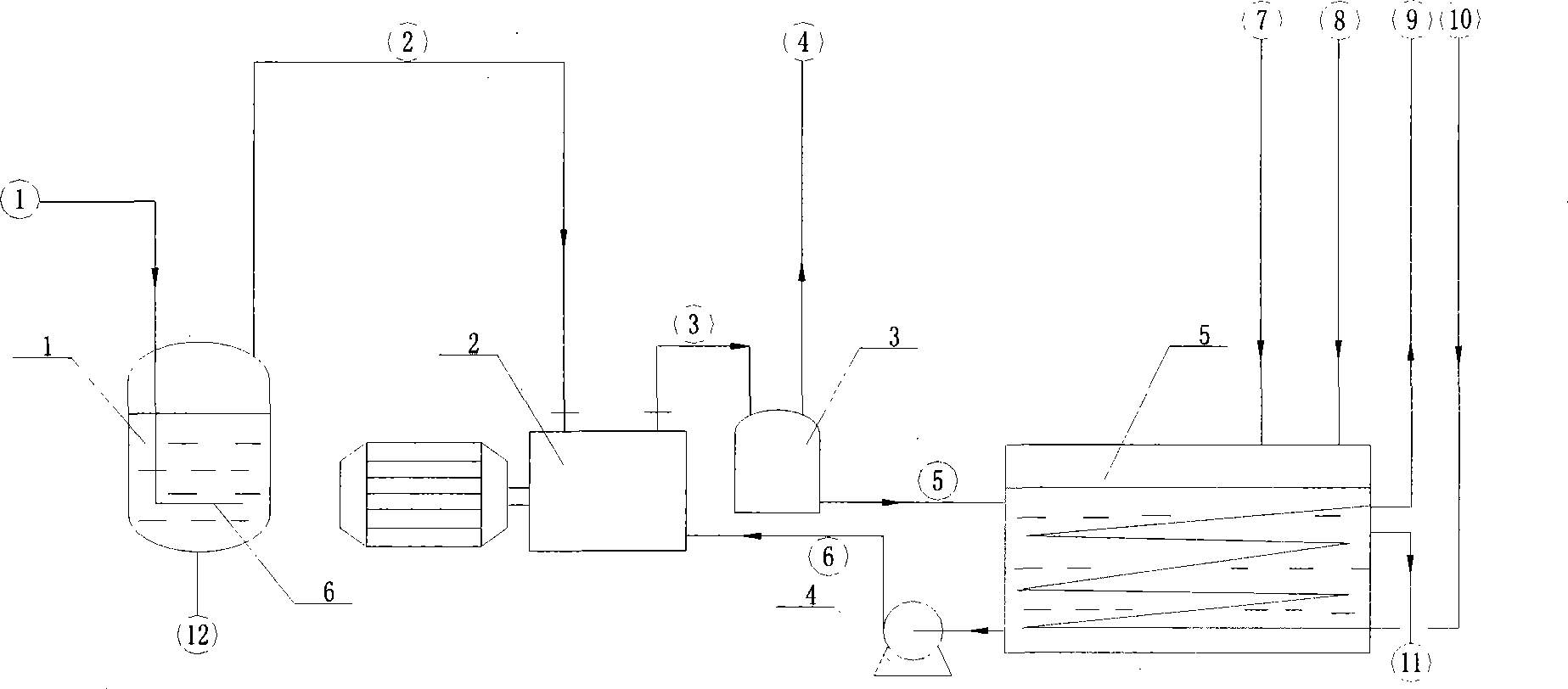

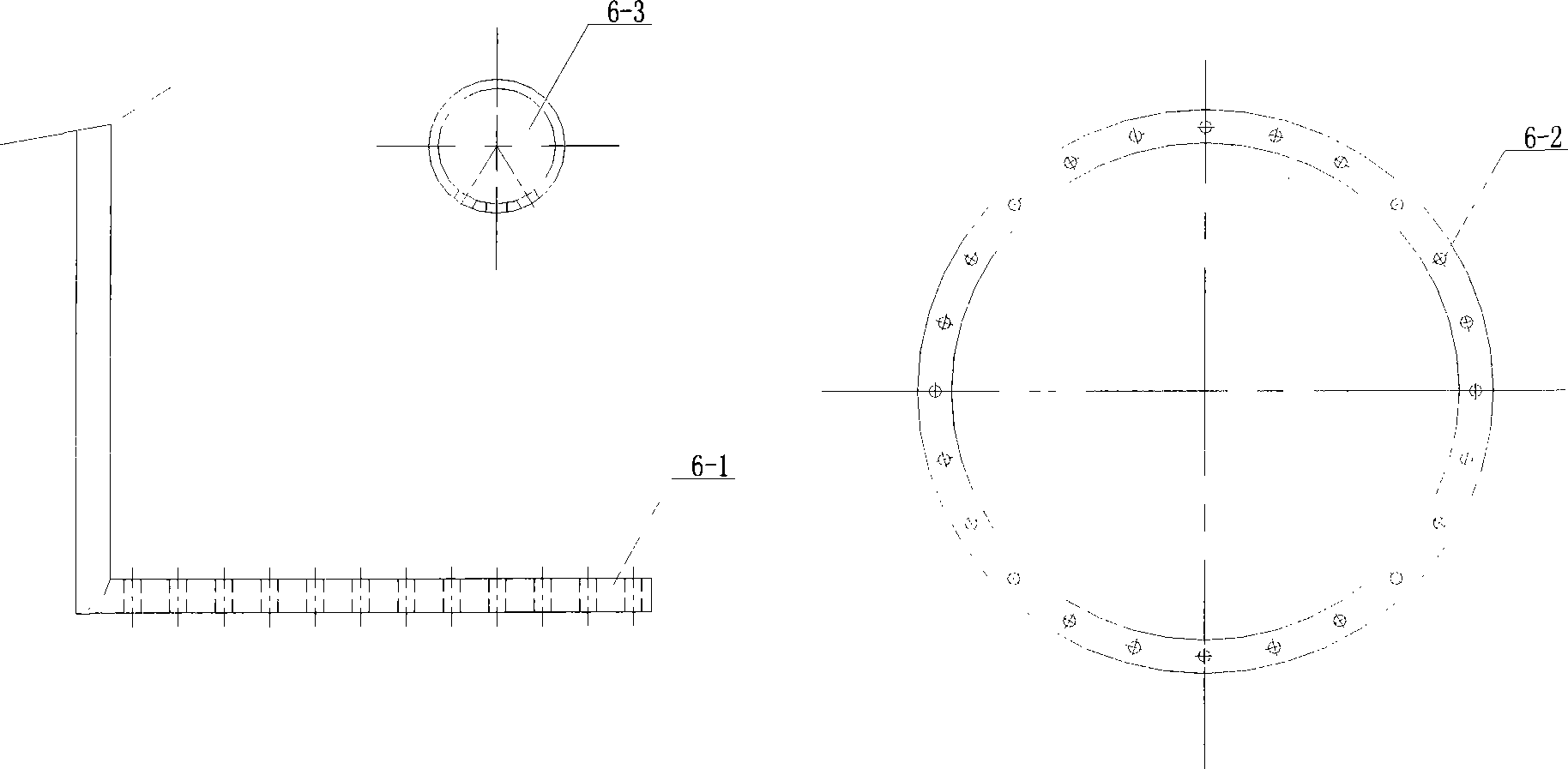

[0011] For the method of waste air compressor oil purification vacuum system methyl isobutyl ketone waste gas of the present invention, refer to the attached figure 2 The technical process is described as follows: The concentration of MIBK waste gas in the gas from the concentration and vacuum drying system ① is 800-2500mg / m 3 , enter the vacuum buffer tank 1 equipped with waste air compressor oil 600mm higher than the circular distribution pipe through the intake distribution pipe 6, and after the waste air compressor oil in the buffer tank 1 absorbs MIBK gas, it enters through the water ring vacuum pump Gas ② enters the water ring vacuum pump 2; the pumping rate of the water ring vacuum pump 2 is 4-6m 3 / min, the gas containing a small amount of MIBK in the water ring vacuum pump 2 is in full contact with unsaturated circulating water below 25°C, and after further absorbing the MIBK waste gas, it is exhausted by the water ring vacuum pump ③Enters the gas-water separator 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com