Cyclic heating rapid nitridation catalytic cementation process

A cycle heating and nitriding technology, which is applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of large ammonia gas, long time, large power consumption, etc., to improve absorption capacity and reduce exhaust gas Effects of discharge and acceleration of infiltration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

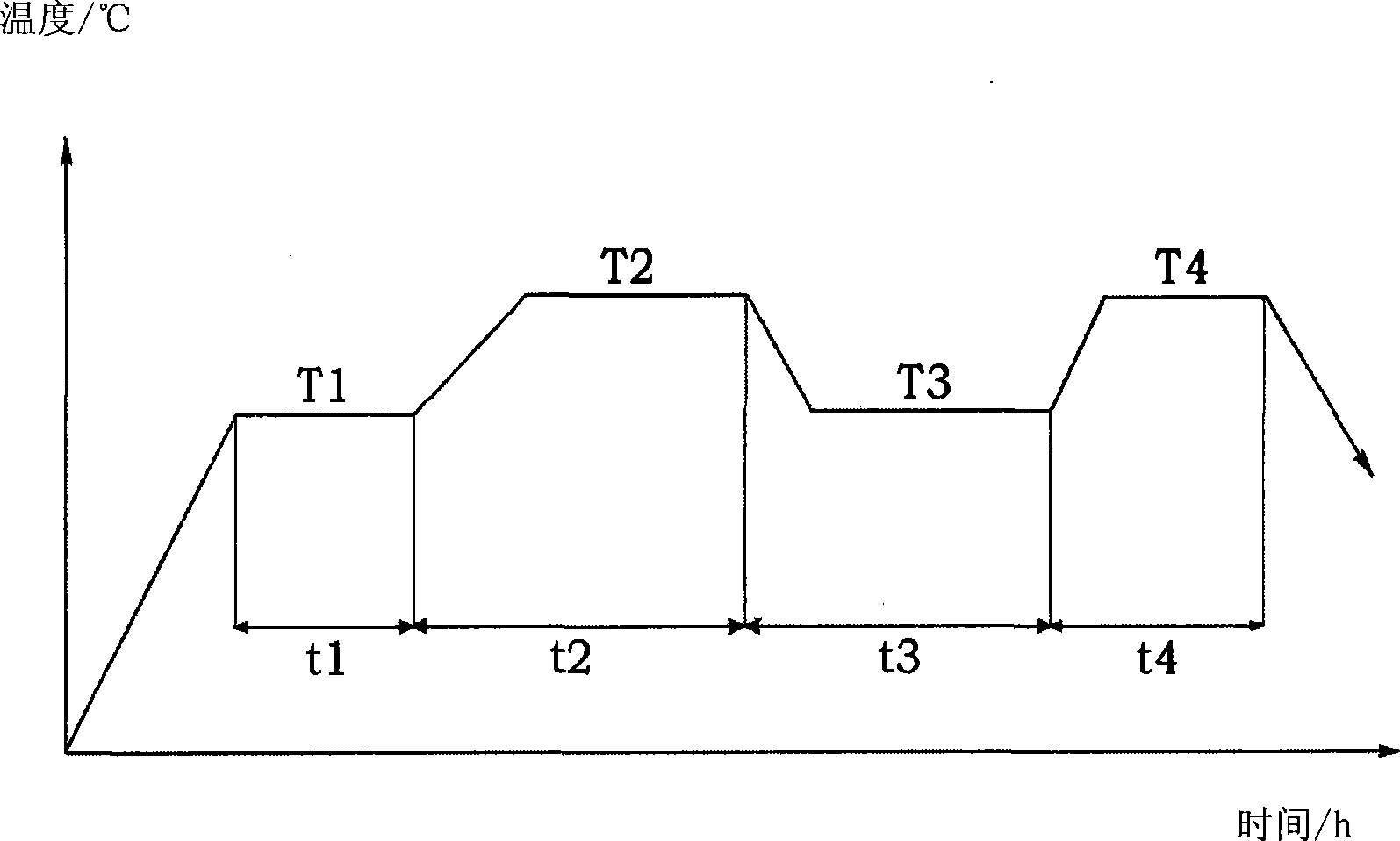

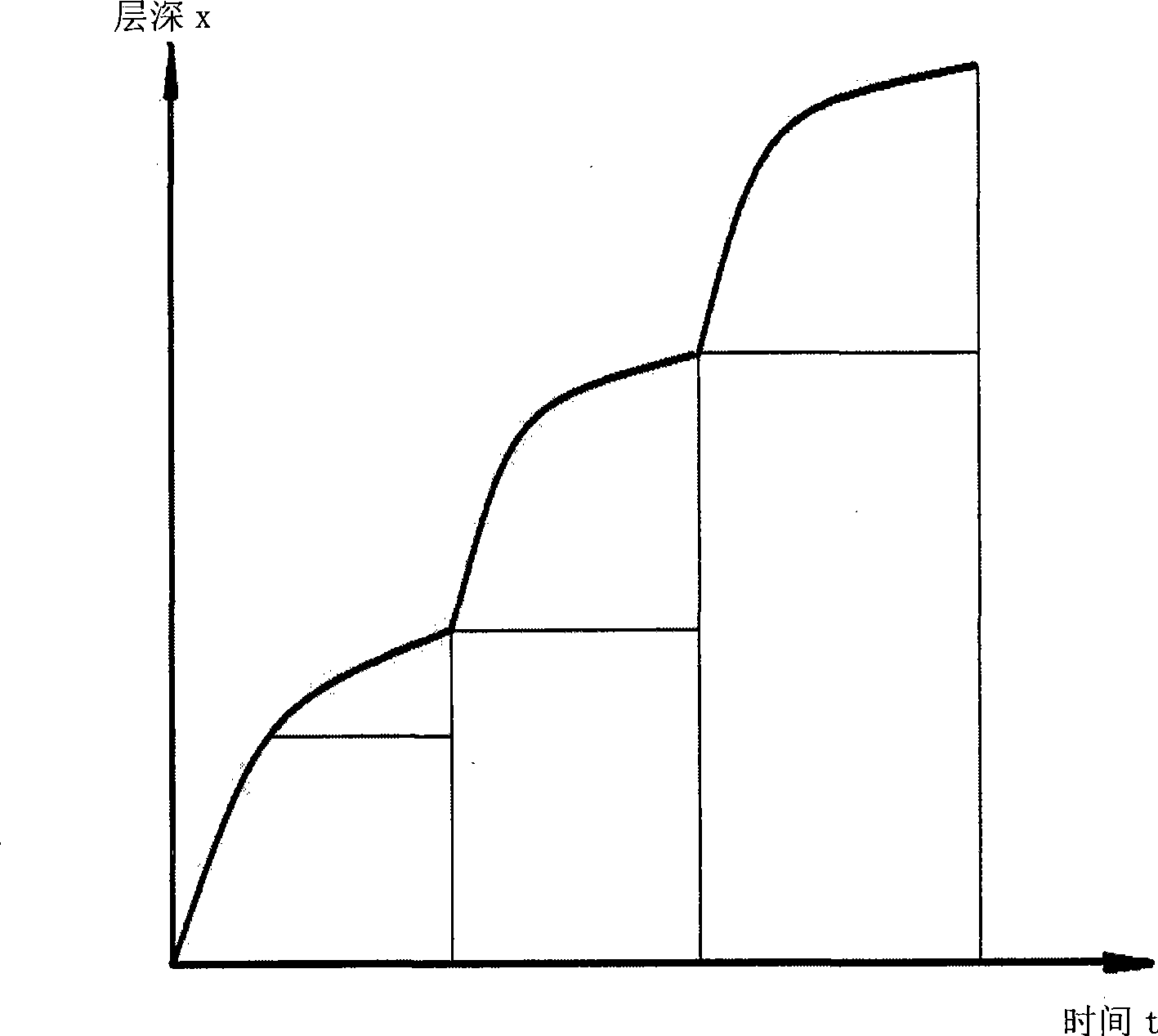

[0013] (1) After loading the workpiece into the nitriding furnace, pass in ammonia gas to discharge the air, heat from room temperature to T1 temperature of 500°C, T2 temperature of 520°C after two stages of heat preservation, and then carry out another T1 temperature of 500°C, T2 temperature is 520°C, two-stage heating and heat preservation, and the ammonia decomposition rate is controlled within the range of 18%, 40%, 30%, 55%-60% for nitriding, making full use of the high-speed stage of strong infiltration, and the depth of nitriding layer and Time is thickened according to multiple parabolas, and the P value of each parabola is different according to each specific process (assuming that the equation of the parabola is X 2 =Pt),

[0014] (2) From nitriding furnace loading, the white powder containing rare earth elements will be mixed with the workpiece, by weight percentage: containing 10% rare earth chloride, 10% ammonium chloride, 50% calcium chloride, and 30% sodium carb...

Embodiment 2

[0016] (1) After loading the workpiece into the nitriding furnace, pass in ammonia gas to discharge the air, heat from room temperature to T1 temperature of 630°C, T2 temperature of 650°C after two stages of heat preservation, and then carry out another T1 temperature of 500°C, The T2 temperature is 520°C, two-stage heating and heat preservation, and the ammonia decomposition rate is controlled within the range of 30%, 45%, 35%, 58%-60% for nitriding, making full use of the high-speed stage of strong infiltration, and the depth of nitriding layer and Time is thickened according to multiple parabolas, and the P value of each parabola is different according to each specific process (assuming that the equation of the parabola is X 2 =Pt),

[0017] (2), from the nitriding furnace, the white powder containing rare earth elements will be mixed with the workpiece, by weight percentage: containing 3% rare earth chloride, 15% ammonium chloride, 42% calcium chloride, 40% sodium carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com