Liquid crystal oriented agent, liquid crystal oriented film and liquid crystal indicator element

A technology of liquid crystal aligning agent and liquid crystal aligning film, applied in the directions of liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of coating and printability, and achieve excellent printability, high pretilt angle, and high voltage retention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0145] 196 g (1.0 mol) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride, and 2,2'-dimethyl-4,4'- Diaminobiphenyl 212g (1.0 mole) is dissolved in the mixed solvent that is made up of 370g N-methyl-2-pyrrolidone and 3300g gamma-butyrolactone, makes it react at 40 ℃ for 3 hours, obtains about 3700g containing 10 weight % solution of polyamic acid (A-1). The solution viscosity of this solution was 160 mPa·s.

Synthetic example 2

[0147] 98 g (0.50 moles) of 1,2,3,4-cyclobutanetetracarboxylic dianhydride as tetracarboxylic dianhydride and 109 g (0.50 moles) of pyromellitic dianhydride, and 4 as diamine compound, 198g (1.0 mole) of 4'-diaminodiphenylmethane was dissolved in the mixed solvent that is made up of 230g N-methyl-2-pyrrolidone and 2060g gamma-butyrolactone, after making it react at 40 ℃ for 3 hours, 1350 g of (gamma)-butyrolactone was added, and about 3600 g of solutions containing 10 weight% of polyamic acids (A-2) were obtained. The solution viscosity of this solution was 125 mPa·s.

[0148]

Synthetic example 3

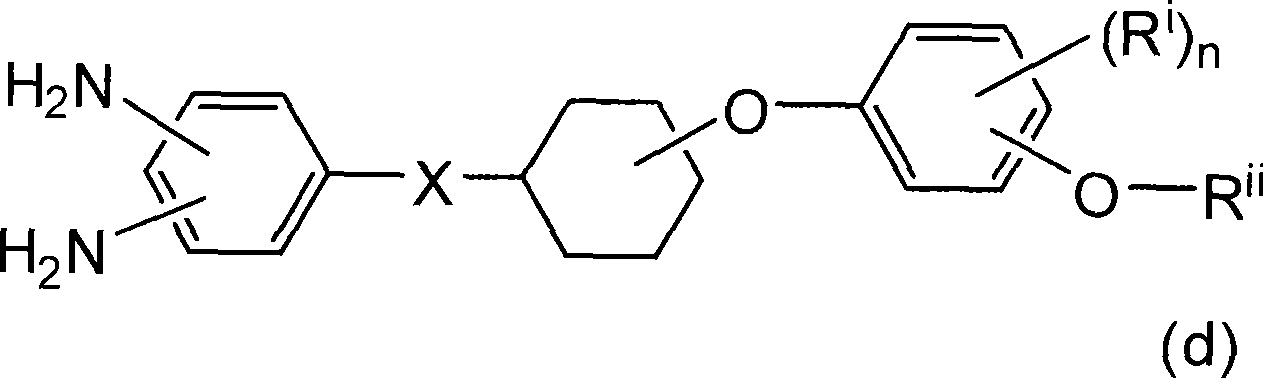

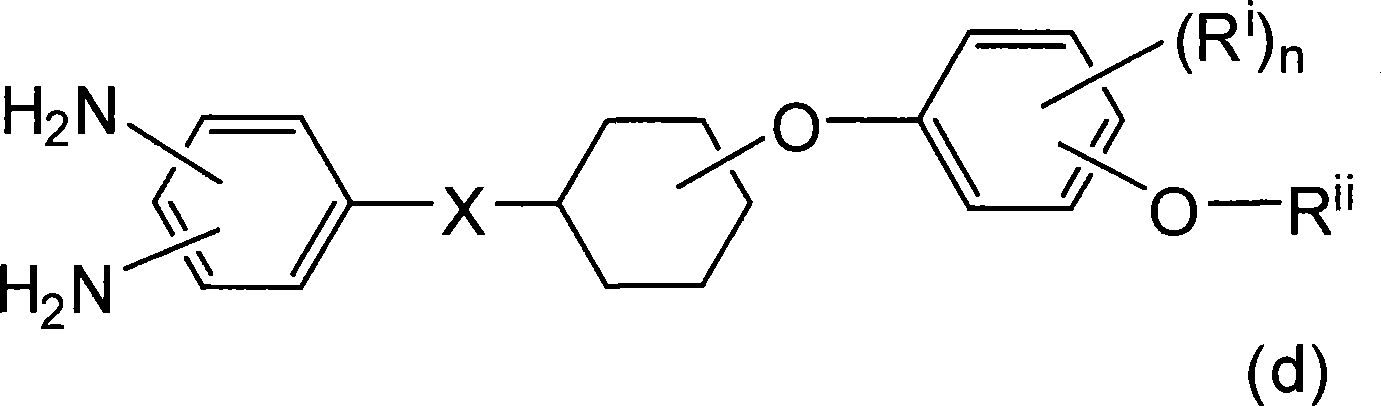

[0150] 112g (0.50 moles) of 2,3,5-tricarboxycyclopentylacetic dianhydride as tetracarboxylic dianhydride and 1,3,3a,4,5,9b-hexahydro-8-methyl-5- (Tetrahydro-2,5-dioxo-3-furyl)-naphthalene[1,2-c]-furan-1,3-dione 157g (0.50 mol), p-phenylenediamine as diamine compound 88g (0.81 mol), 25g (0.10 mol) of diaminopropyltetramethyldisiloxane and 4-(4'-trifluoromethoxyphenoxy) cyclohexyl ester of 3,5-diaminobenzoate ( 33 g (0.080 mol) of the compound represented by the above formula (d-1), and 1.4 g (0.015 mol) of aniline as a monoamine were dissolved in 1250 g of N-methyl-2-pyrrolidone and reacted at 60° C. hours, a solution containing polyamic acid was obtained. A small amount of this solution was taken, and N-methyl-2-pyrrolidone was added to prepare a solution with a polyamic acid concentration of 10% by weight. The measured solution viscosity was 50 mPa·s.

[0151] 2500 g of N-methyl-2-pyrrolidone was added to the obtained polyamic acid solution, and 397 g of pyridine and 410 g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com