Thermoplastic organic-inorganic hybrid material and process for production of the same

A hybrid material, thermoplastic technology, applied in the direction of dyeing polymer organic compound treatment, silicon oxide, silicon dioxide, etc., can solve the problems of no interaction, excellent mechanical strength, etc., and achieve easy manufacturing, excellent mechanical strength, and formability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

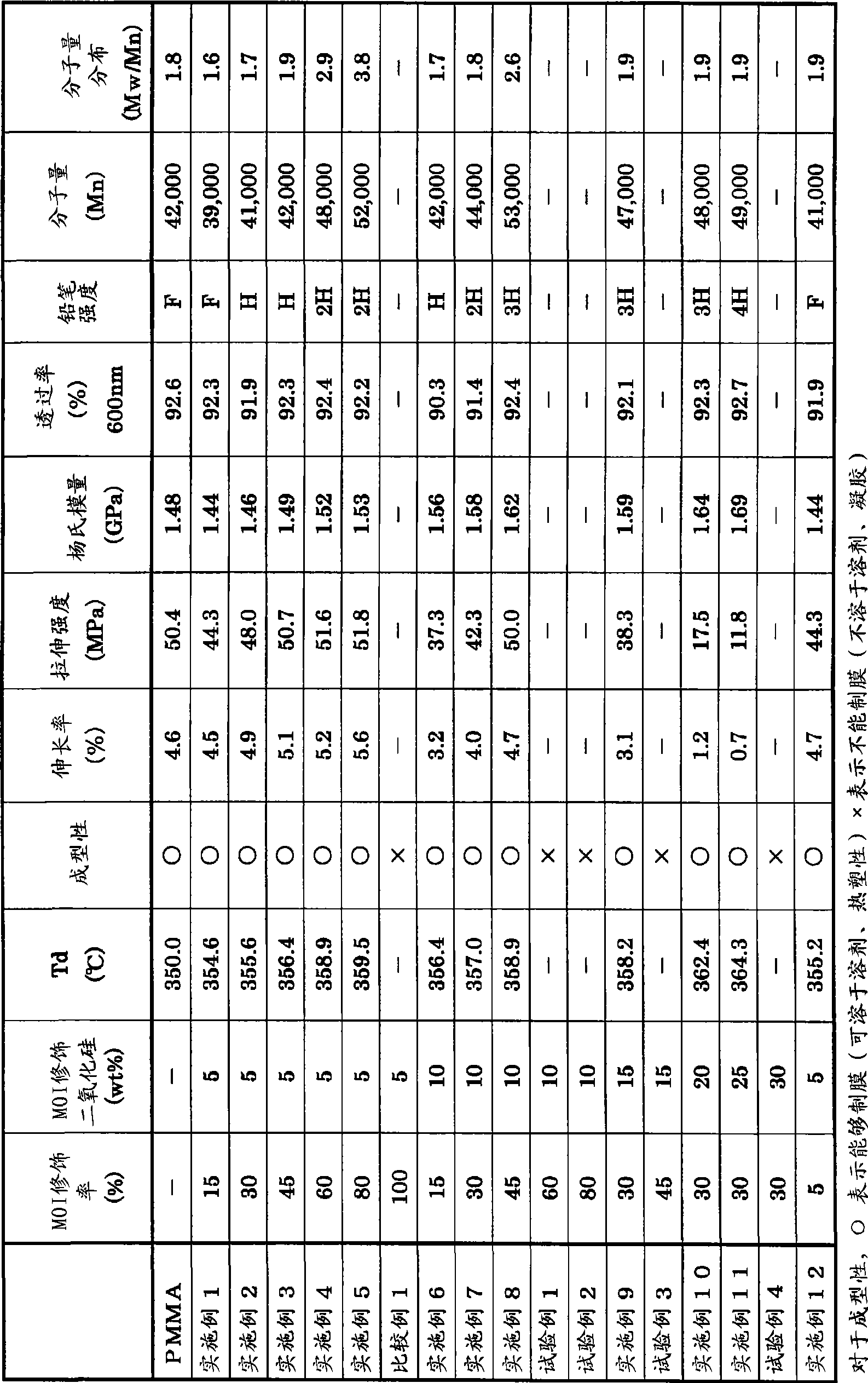

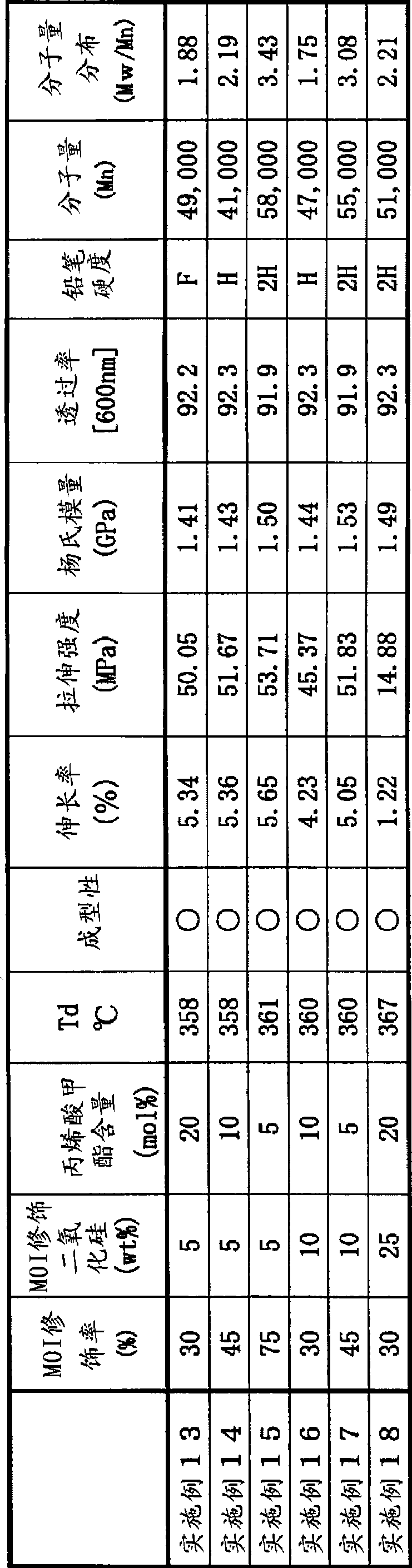

[0031] Hereinafter, embodiments of the embodiments of the invention will be described in detail.

[0032] PMMA-silica hybrid material

[0033]

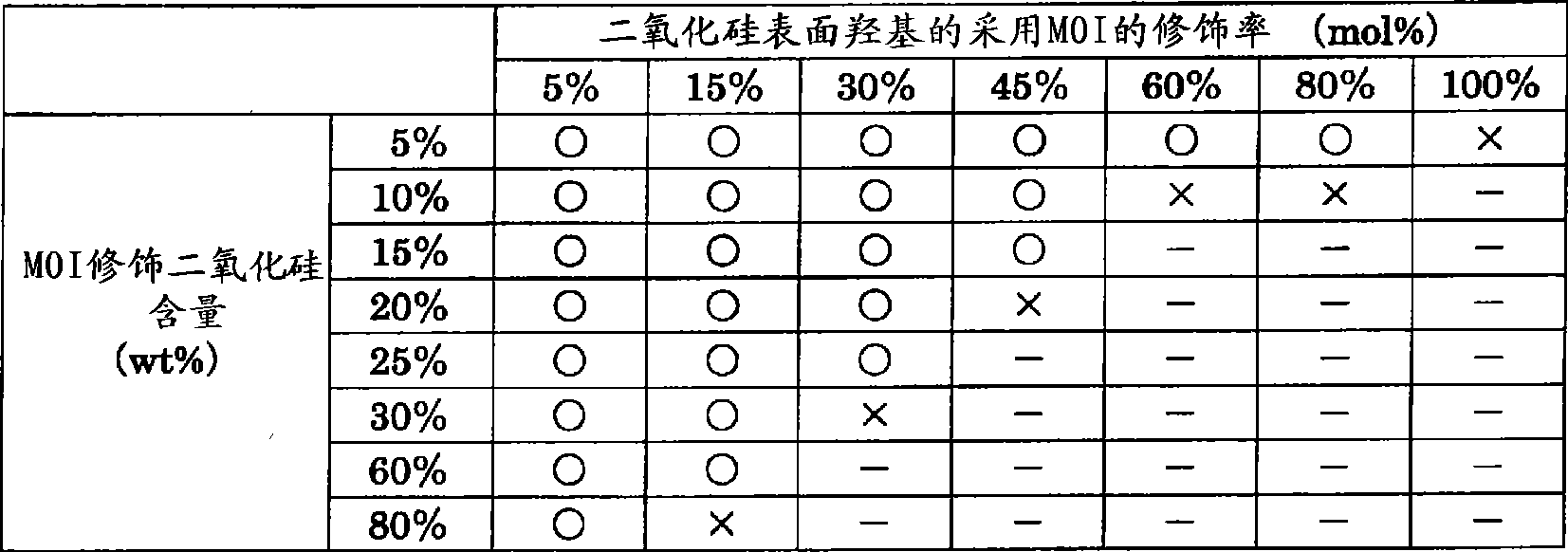

[0034] In the 3-scale flask, methyl ethyl ketone dispersion colloidal silica (MEK-ST particle diameter 10 to 15 nm, silica content by 30% by weight) and isocyanic acid were added in accordance with various proportions. Acryloyloxy) ethyl ester (hereinafter referred to as "MOI"), adding a weight of about 650 ppm relative to colloidal silica (hereinafter referred to as "DBTDL") as a catalyst, stirring at room temperature One day, it gave MOI modified colloidal silica.

[0035]

[0036] The thermometer, cooling tube and stirring pad were mounted in the 4-mouth flask, and after the flask was replaced with nitrogen, methyl ethyl ketone, grease-benzoyl and MOI were added, and the flask was heated in the oil bath. After 80 ° C, the mixture was stirred at a rate of about 120 rpm, while 15 minutes was added dropwise, and the mixture was comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com