Tungsten carbide/conductive polyaniline composite particle and preparation method thereof

A technology of tungsten carbide particles and conductive polyaniline, which is applied in the field of tungsten carbide/conductive polyaniline composite particles and their preparation, can solve the problems of high price of precious metals, limited use of widely used, high production cost, etc., and achieves low cost and simple preparation process. Easy and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

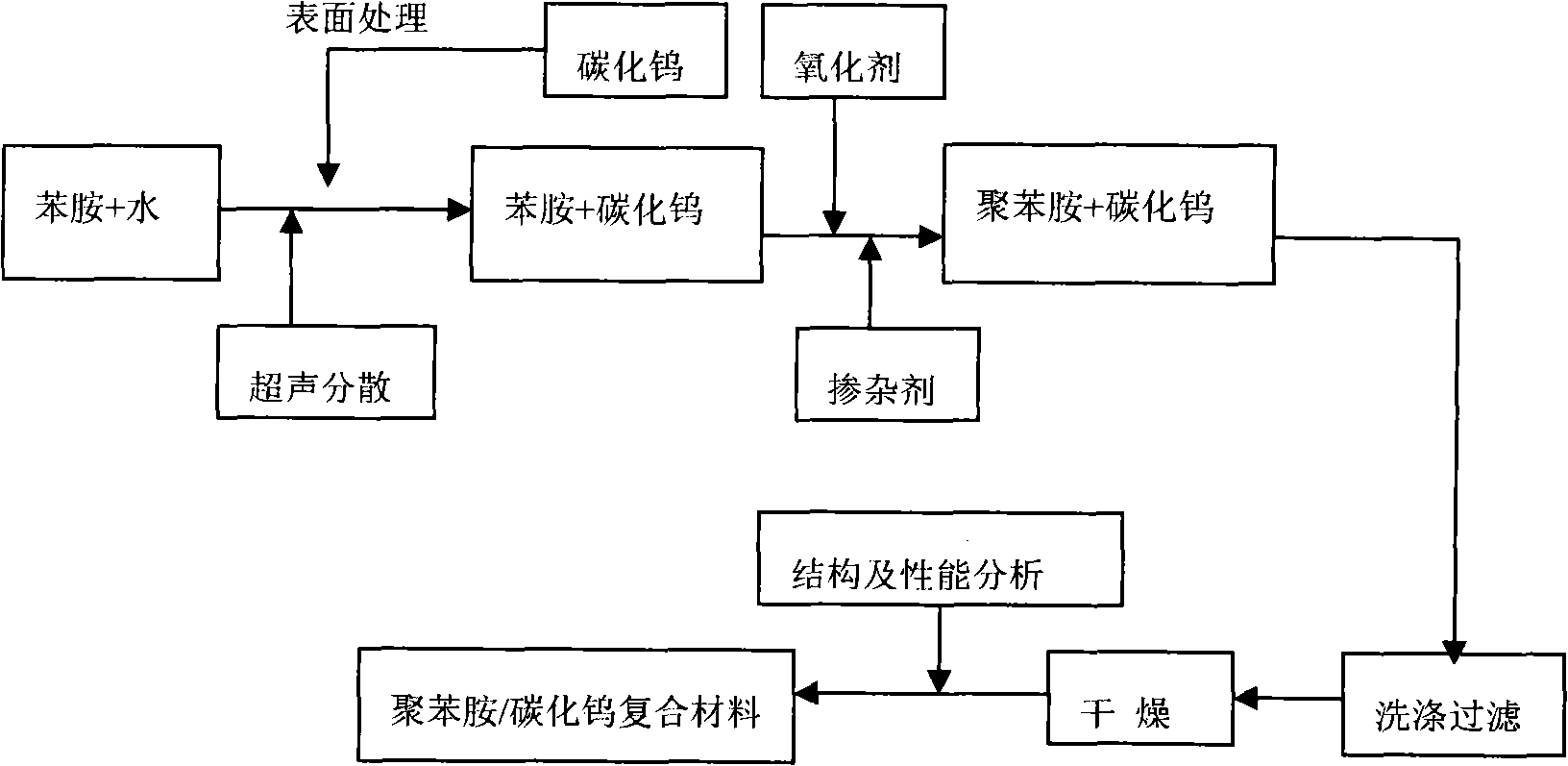

Method used

Image

Examples

Embodiment 1

[0023] ①Preparation of tungsten carbide seed particles: disperse 0.235g tungsten carbide into 25mL water, add 0.1g polyvinyl alcohol, and raise the temperature to 60°C for 0.5 hours, then turn to ultrasonic dispersion for 30 minutes to obtain tungsten carbide emulsion;

[0024] ②Swelling of aniline monomer in tungsten carbide particles: Add 4.7g of aniline to 25mL water, ultrasonically disperse and stir for 15 minutes, then add the tungsten carbide emulsion obtained in step ①, continue ultrasonically disperse and stir for 30 minutes to obtain a mixed emulsion;

[0025] ③ Aniline is polymerized on the surface of tungsten carbide particles to form composite particles: under magnetic stirring, transfer the mixed emulsion prepared in step ② to a three-necked bottle, and after the system is cooled to 15°C in an ice-water bath, continue to stir for 15 minutes; then Add 16mL of ammonium persulfate solution with a concentration of 2.5mol / L, start to add 40mL of sulfuric acid solution w...

Embodiment 2

[0027] ①Preparation of tungsten carbide seed particles: disperse 0.9g tungsten carbide into 25mL water, add 0.3g polyvinyl alcohol, and raise the temperature to 70°C for 1.5 hours with magnetic stirring, then turn to ultrasonic dispersion for 40 minutes to obtain tungsten carbide emulsion;

[0028] ②Swelling of aniline monomer in tungsten carbide particles: Add 2.5g of aniline into 25mL of water, ultrasonically disperse and stir for 20 minutes, then add the tungsten carbide emulsion obtained in step ①, continue ultrasonically dispersing and stir for 40 minutes to obtain a mixed emulsion;

[0029] ③ Aniline is polymerized on the surface of tungsten carbide particles to form composite particles: under magnetic stirring, transfer the mixed emulsion prepared in step ② to a three-necked bottle, and after the system is cooled to 10°C in an ice-water bath, continue to stir for 20 minutes; then Add 21.5mL of hydrogen peroxide solution with a concentration of 1.25mol / L, and start to dro...

Embodiment 3

[0031] ①Preparation of tungsten carbide seed particles: disperse 1.75g tungsten carbide into 25mL water, add 0.5g polyvinyl alcohol, and raise the temperature to 75°C for 2.5 hours with magnetic stirring, then switch to ultrasonic dispersion for 80 minutes to obtain tungsten carbide emulsion;

[0032] ②Swelling of aniline monomer in tungsten carbide particles: Add 5g of aniline into 25mL of water, ultrasonically disperse and stir for 30 minutes, then add the tungsten carbide emulsion obtained in step ①, continue ultrasonically disperse and stir for 45 minutes to obtain a mixed emulsion;

[0033] ③ Aniline is polymerized on the surface of tungsten carbide particles to form composite particles: under magnetic stirring, transfer the mixed emulsion prepared in step ② to a three-necked bottle, and after the system is cooled to 20°C in an ice-water bath, continue to stir for 30 minutes; then Add 107 mL of potassium iodate solution with a concentration of 1 mol / L, and start to drop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com