Graphene modified nylon 66 composite material and preparation method thereof

A graphene modification and composite material technology, applied in the field of composite materials, can solve problems such as inability to realize large-scale industrial production, cumbersome in-situ polymerization preparation process, use of organic solvents, etc., and achieve good compatibility and interaction, The preparation process is simple and easy, and the dispersibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the mass parts of each raw material are as follows: 450 parts of nylon 66, 0.09 parts of graphite oxide, 7 parts of polyvinyl alcohol, and 170 parts of water.

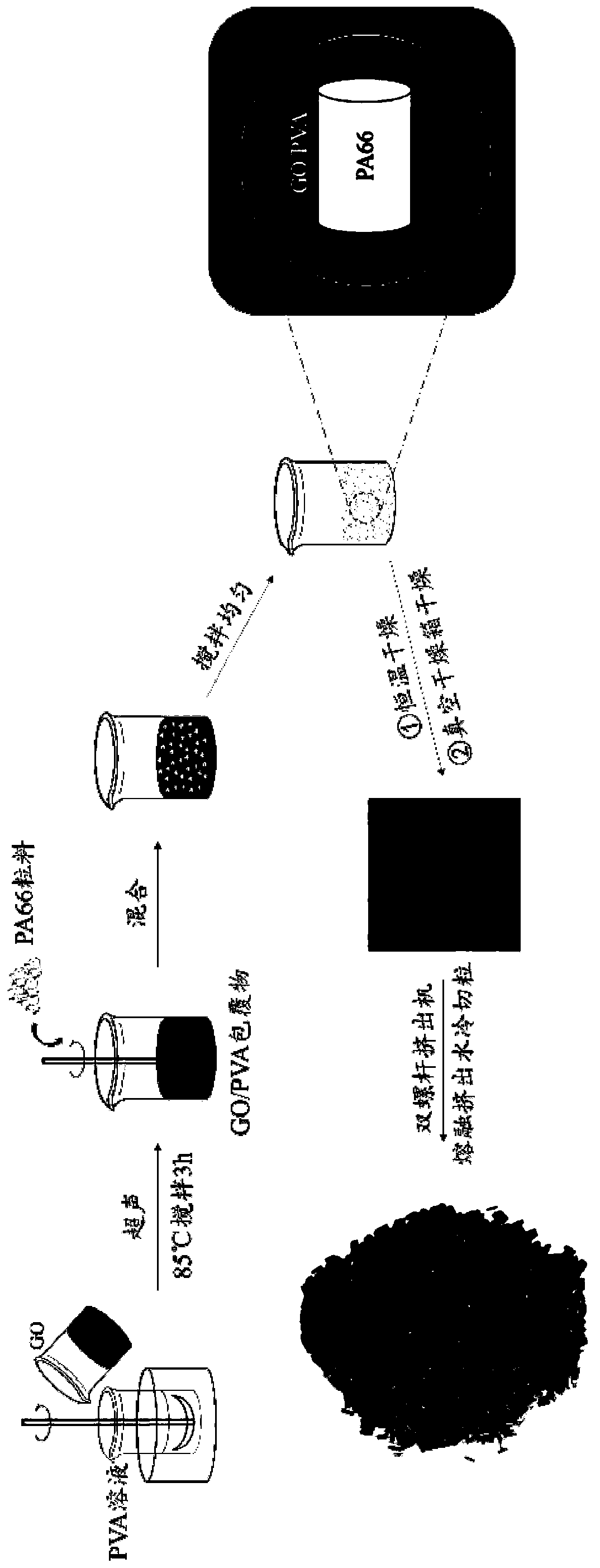

[0039] Such as figure 1 As shown, the specific preparation process is as follows:

[0040] (1) 0.09 parts of graphite oxide and 7 parts of polyvinyl alcohol are added to 30 parts of water and 140 parts of water respectively, and the graphite oxide is ultrasonically dispersed to obtain a graphene oxide dispersion;

[0041] (2) the graphene oxide dispersion liquid obtained in step (1) is mixed with polyvinyl alcohol solution, and ultrasonically dispersed to obtain a uniformly dispersed graphene oxide / polyvinyl alcohol mixed liquid;

[0042] (3) Place the mixed solution obtained in step (2) in a constant temperature water bath at 85° C., and stir for 3 hours at a speed of 360 rpm to obtain a viscous graphene oxide / polyvinyl alcohol coating material;

[0043] (4) The cladding material of step (...

Embodiment 2

[0048] In this embodiment, the mass parts of each raw material are as follows: 450 parts of nylon 66, 0.18 parts of graphite oxide, 7 parts of polyvinyl alcohol, and 200 parts of water.

[0049] Concrete preparation process is as follows:

[0050] (1) 0.18 parts of graphite oxide and 7 parts of polyvinyl alcohol are added to 60 parts of water and 140 parts of water respectively, and graphite oxide is ultrasonically dispersed to obtain a graphene oxide dispersion;

[0051] (2) the graphene oxide dispersion liquid obtained in step (1) is mixed with polyvinyl alcohol solution, and ultrasonically dispersed to obtain a uniformly dispersed graphene oxide / polyvinyl alcohol mixed liquid;

[0052] (3) Place the mixed solution obtained in step (2) in a constant temperature water bath at 85° C., and stir for 3 hours at a speed of 360 rpm to obtain a viscous graphene oxide / polyvinyl alcohol coating material;

[0053] (4) The cladding material of step (3) gained is physically mixed with 4...

Embodiment 3

[0058] In this embodiment, the mass parts of each raw material are as follows: 450 parts of nylon 66, 0.27 parts of graphite oxide, 7 parts of polyvinyl alcohol, and 230 parts of water.

[0059] Concrete preparation process is as follows:

[0060] (1) 0.27 parts of graphite oxide and 7 parts of polyvinyl alcohol are added to 90 parts of water and 140 parts of water respectively, and graphite oxide is ultrasonically dispersed to obtain a graphene oxide dispersion;

[0061] (2) the graphene oxide dispersion liquid obtained in step (1) is mixed with polyvinyl alcohol solution, and ultrasonically dispersed to obtain a uniformly dispersed graphene oxide / polyvinyl alcohol mixed liquid;

[0062] (3) Place the mixed solution obtained in step (2) in a constant temperature water bath at 85° C., and stir for 3 hours at a speed of 360 rpm to obtain a viscous graphene oxide / polyvinyl alcohol coating material;

[0063] (4) The coating material obtained in step (3) is physically mixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com