Ordered mesoporous silicon-dioxide-substrate fluorescence nanometer material and preparing method thereof

A technology of fluorescent nanomaterials and mesoporous silica, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of uneven dispersion of fluorescent groups, susceptibility to environmental erosion, low fluorescence quantum yield, etc., and achieve synthesis Simple and easy process, good fluorescence stability, high fluorescence quantum yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, with Rhodamine B (RhB) and aminopropyltriethoxysilane (APTES) as raw materials, dry N, N-dimethylformamide (DMF) as solvent, 1-ethyl-(3 -Dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl) as catalyst and dehydrating agent, stirred in anhydrous and light-proof environment for 24 hours, prepared silane coupling agent with RhB fluorescent functional group (RhB-APTES).

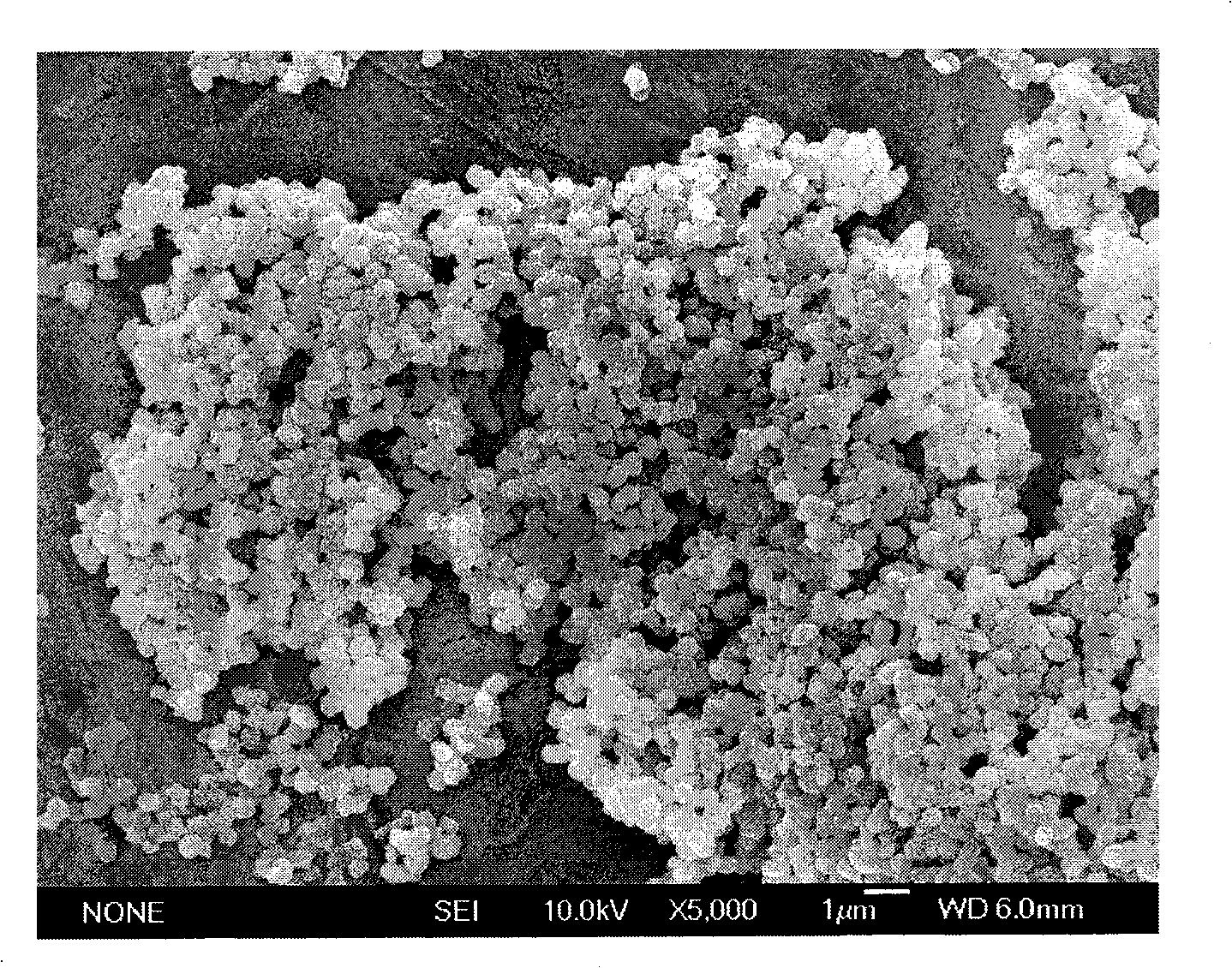

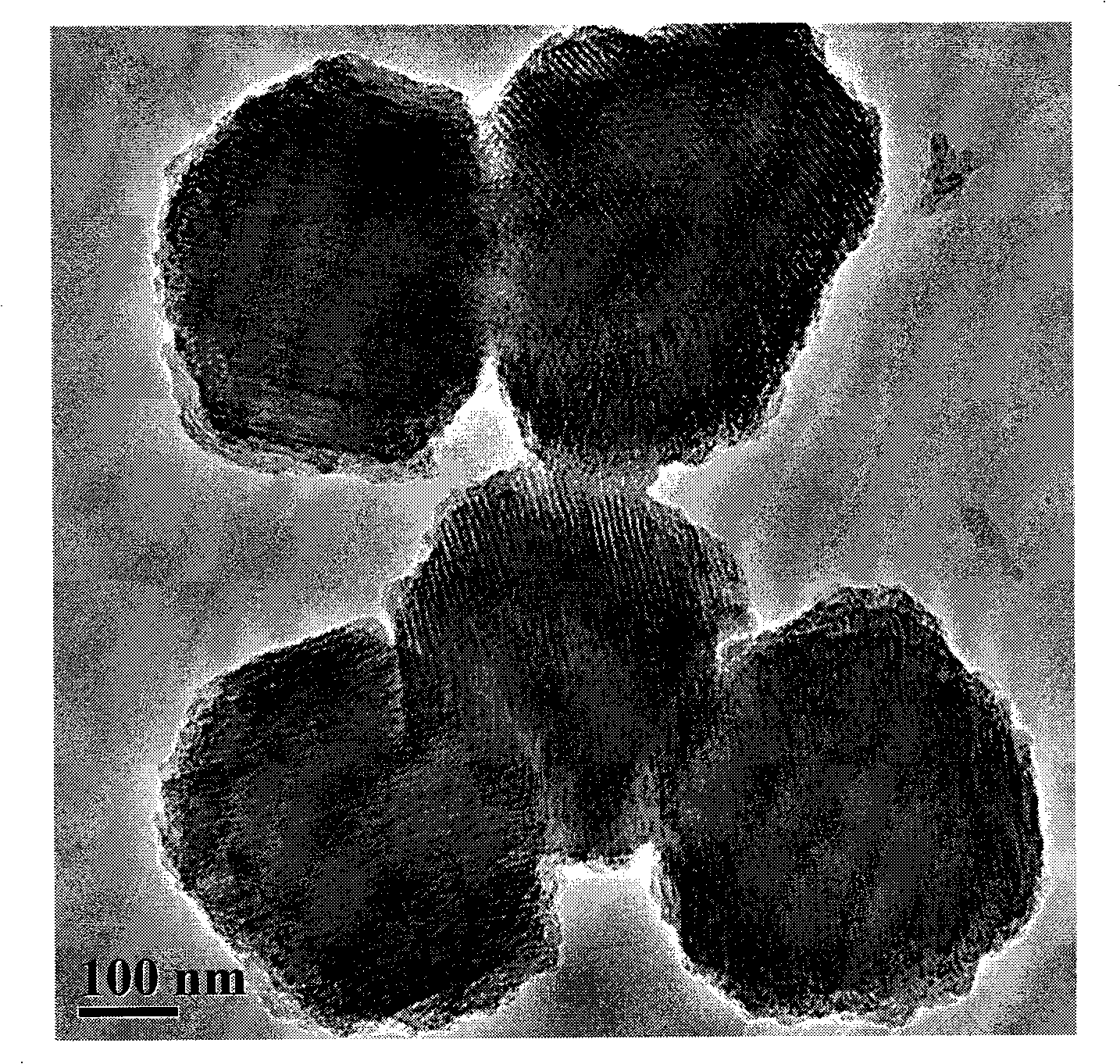

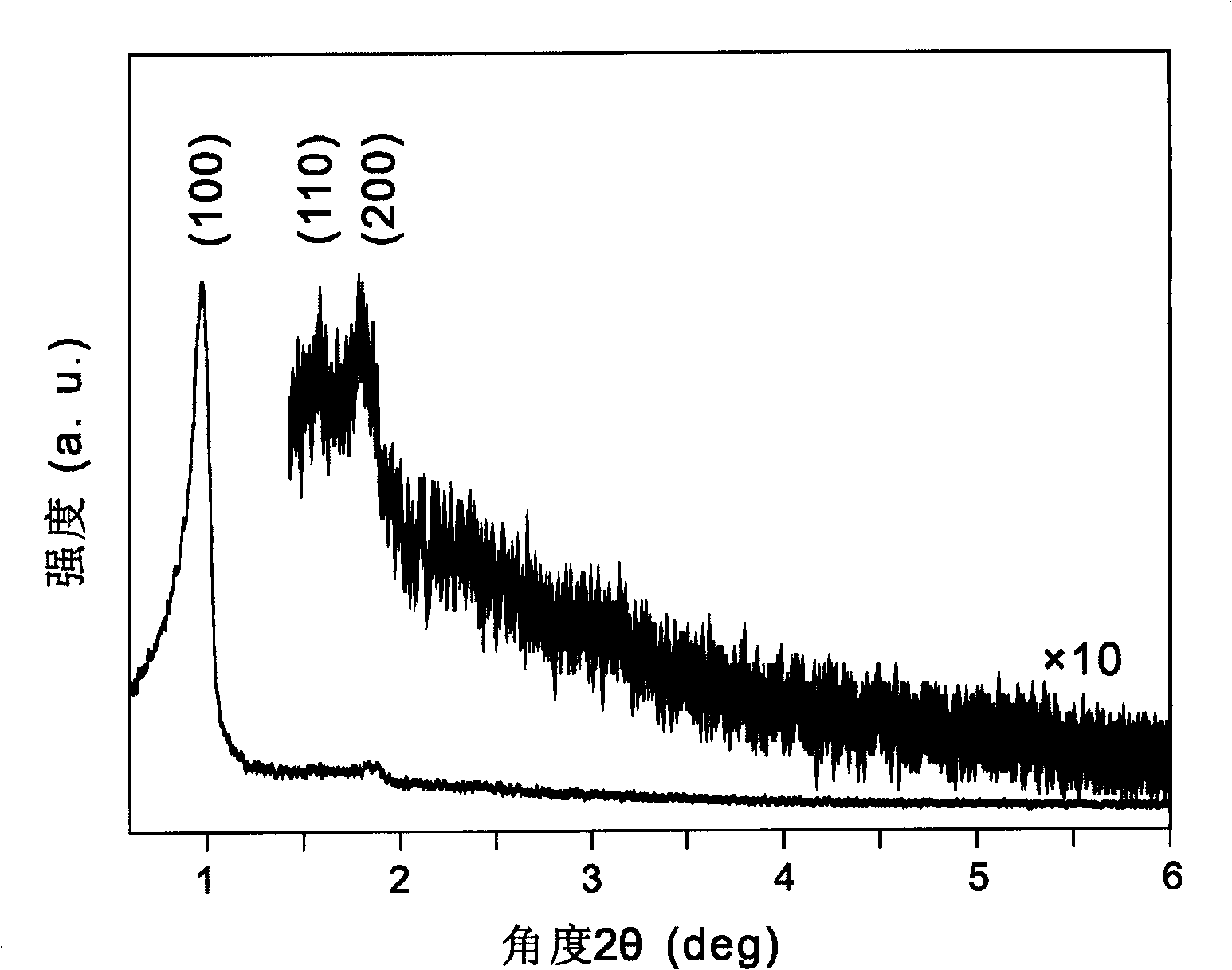

[0034] 1.2gP123 and 0.4gZrOCl 2 ·8H 2Add O together to 100mL 2mol / L hydrochloric acid solution, stir at 35°C to dissolve completely, and then add 0.02gRhB-APTES to the system. Add 2.1g TEOS after 30 minutes, continue stirring for 24 hours, then centrifuge and wash. Finally, it was refluxed for 6 hours in 250 mL of ethanol solution of hydrochloric acid (0.5% by volume), centrifuged and dried. The obtained ordered mesoporous silica-based fluorescent nanomaterial has an average particle diameter of 400nm, an average pore diameter of 4.8nm, and a pore volume of 0.7cm 3 g -1 , BET specific su...

Embodiment 2

[0036] Firstly, RhB and APTES were used as raw materials, dry DMF was used as solvent, EDC·HCl was used as catalyst and dehydrating agent, and the silane coupling agent RhB- APTES.

[0037] 1.2gP123 and 0.8gZrOCl 2 ·8H 2 Add O together into 100mL 2mol / L hydrochloric acid solution, stir at 35°C to dissolve completely, and then add 0.4gRhB-APTES to the system. After 30 minutes, add 2 g of methyl orthosilicate, continue to stir for 24 hours, then centrifuge and wash. Finally, it was refluxed for 6 hours in 250 mL of ethanol solution of hydrochloric acid (0.5% by volume), centrifuged and dried. The obtained ordered mesoporous silica-based fluorescent nanomaterial has an average particle size of 200 nm, an average pore size of 4.8 nm, and a pore volume of 0.7 cm 3 g -1 , BET specific surface area is 700m 2 g -1 . The grafting rate of the obtained ordered mesoporous silica-based fluorescent nanomaterial is 0.13 RhB functional groups / nm -2 , the fluorescence quantum yield is...

Embodiment 3

[0039] Firstly, using fluorescein isothiocyanate (FITC) and aminopropyltrimethoxysilane (APTMS) as raw materials, using absolute ethanol as solvent, stirring in anhydrous and light-proof environment for 24 hours, prepared the fluorescent functional group with FITC Silane coupling agent (FITC-APTMS).

[0040] 1gF127 and 1gZnCl 2 Add together 100mL 2mol / L hydrochloric acid solution, stir at 38°C to dissolve completely, then add 0.5g FITC-APTMS to the system. Add 2.1g TEOS after 30 minutes, continue stirring for 24 hours, then centrifuge and wash. Finally, it was refluxed for 6 hours in 250 mL of ethanol solution of hydrochloric acid (0.5% by volume), centrifuged and dried. The obtained ordered mesoporous silica-based fluorescent nanomaterials have an average particle diameter of 350 nm, an average pore diameter of 5 nm, and a pore volume of 0.8 cm 3 g -1 , BET specific surface area is 680m 2 g -1 . The obtained ordered mesoporous silica-based fluorescent nanomaterials hav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com