PEG-grafted polysulfone or polyethersulfone hollow fiber membrane and its preparation method and use

A technology of polyethersulfone and fiber membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as inability to deduce membrane-forming parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

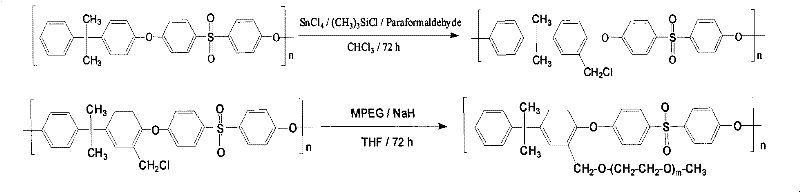

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the PEG-grafted polysulfone or polyethersulfone hollow fiber membrane comprises the following steps:

[0032] a) After the compound represented by molecular formula I and the compound represented by molecular formula II are mixed in a ratio of 1:3 to 9, they are dissolved in a solvent with a weight ratio of 15 to 30%. The solvent is N-methylpyrrolidone and dimethylformamide , dimethylacetamide and dimethyl sulfoxide or a mixture of several;

[0033] b) stirring, dissolving for 10 to 12 hours, degassing, and obtaining the spinning stock solution;

[0034] c) Two concentric hollow fiber spinnerets are used to extrude the spinning dope through the spinnerets. The ambient temperature is 20-25°C, the relative humidity is 30-80%, and the extrusion speed is 5-20ml / min. The as-spun fibers go through 10-30cm in the environment and then solidify and form in a water bath with a temperature of 50-80°C. The line speed is 5-40m / min.

[0035] The hollow fi...

Embodiment 1

[0047] The PEG molecular weight is 350, the PEG-polysulfone graft product of graft rate 32%, mixes with polysulfone by the ratio of 1: 3, and dissolves in N-methylpyrrolidone by 15% (w / v), stirs Let it dissolve completely for 12 hours and remove the air bubbles. When the room temperature is 20°C and the relative humidity is 50%, the spinning solution is extruded through two concentric hollow fiber spinnerets at a speed of 5ml / min. It is solidified and formed in water at 50°C, and the fluid linear velocity is 5.5m / min.

[0048] The inner diameter of the obtained novel hollow fiber membrane is 1000 μm, the wall thickness is 100 μm, the porosity detected by mercury porosimetry is 78%, the average pore diameter is 0.8 μm, and no albumin interception can be detected.

Embodiment 2

[0050] The PEG molecular weight is 750, the PEG-polyethersulfone graft product of graft rate 16%, mixes with polyethersulfone by the ratio of 1:5, and dissolves in dimethylacetamide by 20% (w / v) , stirred for 12 hours to dissolve it completely, and remove air bubbles. When room temperature is 25°C and relative humidity is 70%, the spinning solution is extruded through two concentric hollow fiber spinnerets at a speed of 12ml / min. It is solidified and formed in water at 75°C, and the fluid linear velocity is 10m / min.

[0051] The inner diameter of the obtained novel hollow fiber membrane is 700 μm, the wall thickness is 100 μm, the porosity detected by mercury porosimetry is 74%, the average pore diameter is 0.11 μm, and the albumin rejection rate is 65%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com