Dissymmetrical supercapacitor with high energy density and method for preparing same

A supercapacitor, high energy density technology, applied in the direction of capacitors, electrolytic capacitors, capacitor parts, etc., can solve the problem of low energy density of capacitors, achieve the effect of widening the working voltage range, increasing specific capacitance, and increasing energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] α-MnO Synthesized by Liquid Phase Precipitation 2 , Weigh 0.40g of potassium permanganate and put it in a flask, add 15ml of deionized water to make solution A. Weigh 0.93g of manganese acetate and put it in a flask, add 25ml of deionized water to make solution B. Solution B was slowly dropped into solution A, and the mixture was continuously stirred for 6h. The reactant was filtered, washed with ethanol or water, and the collected product was dried at 110°C, and the product α-MnO 2 The BET specific surface area is 147m 2 / g; the α-MnO 2 , acetylene black and polytetrafluoroethylene by α-MnO 2 : Acetylene black: polytetrafluoroethylene = 70wt%: 20wt%: 10wt% mixed to form a manganese oxide anode;

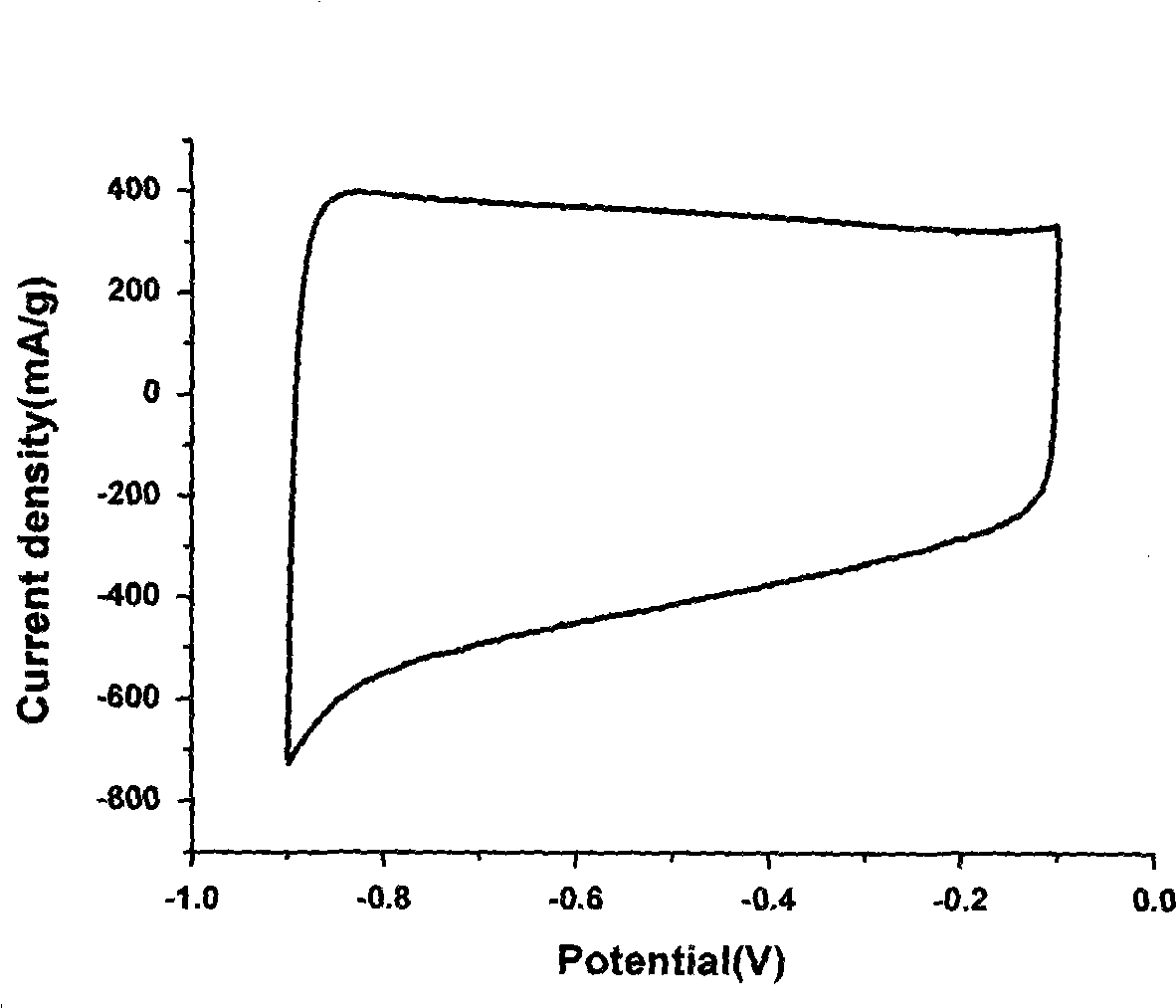

[0036] Porous carbon and polytetrafluoroethylene are mixed according to porous carbon: polytetrafluoroethylene = 90wt%: 10wt% to form a porous carbon cathode, and the BET specific surface area of nitrogen-containing porous carbon is 2492m 2 / g;

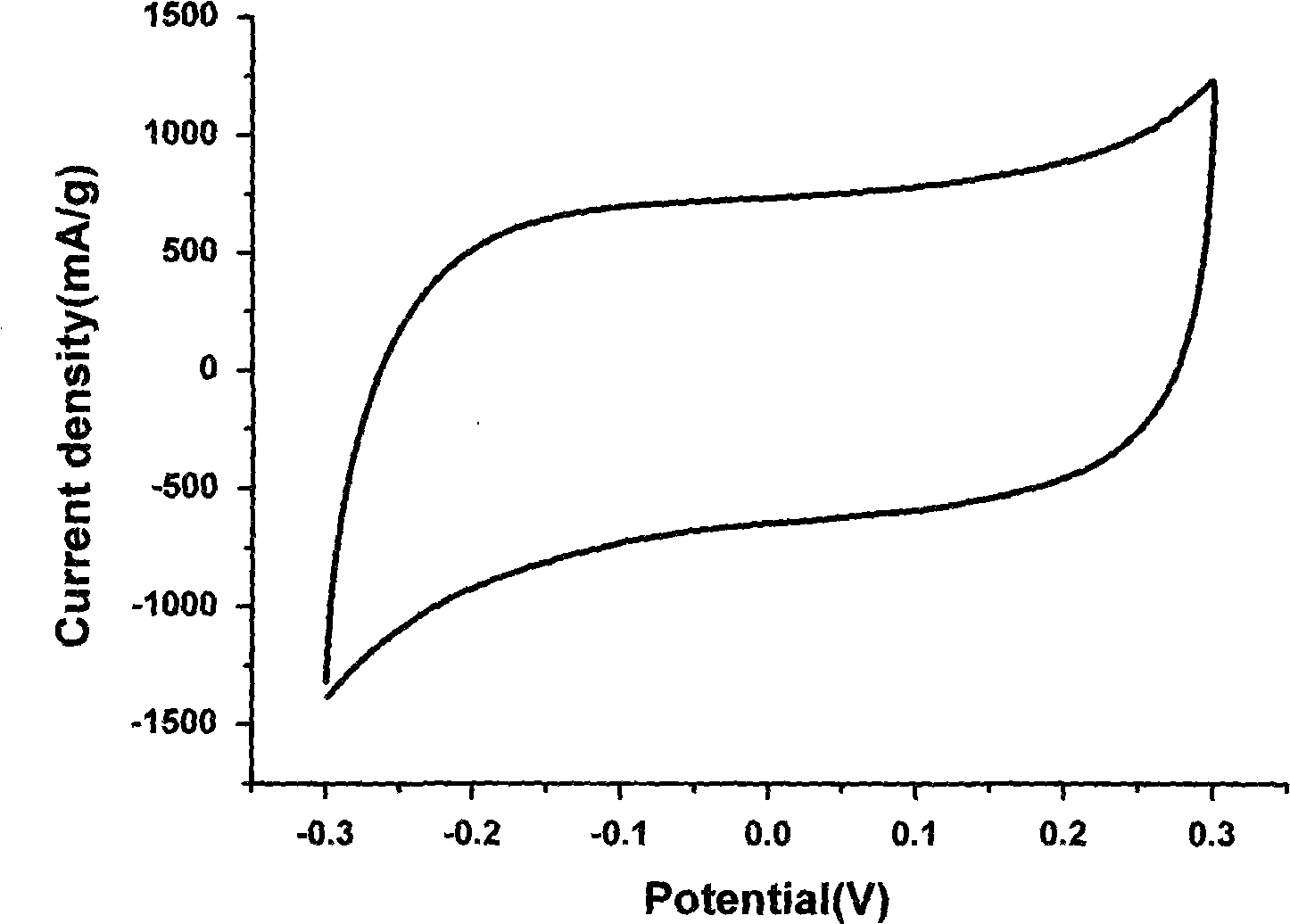

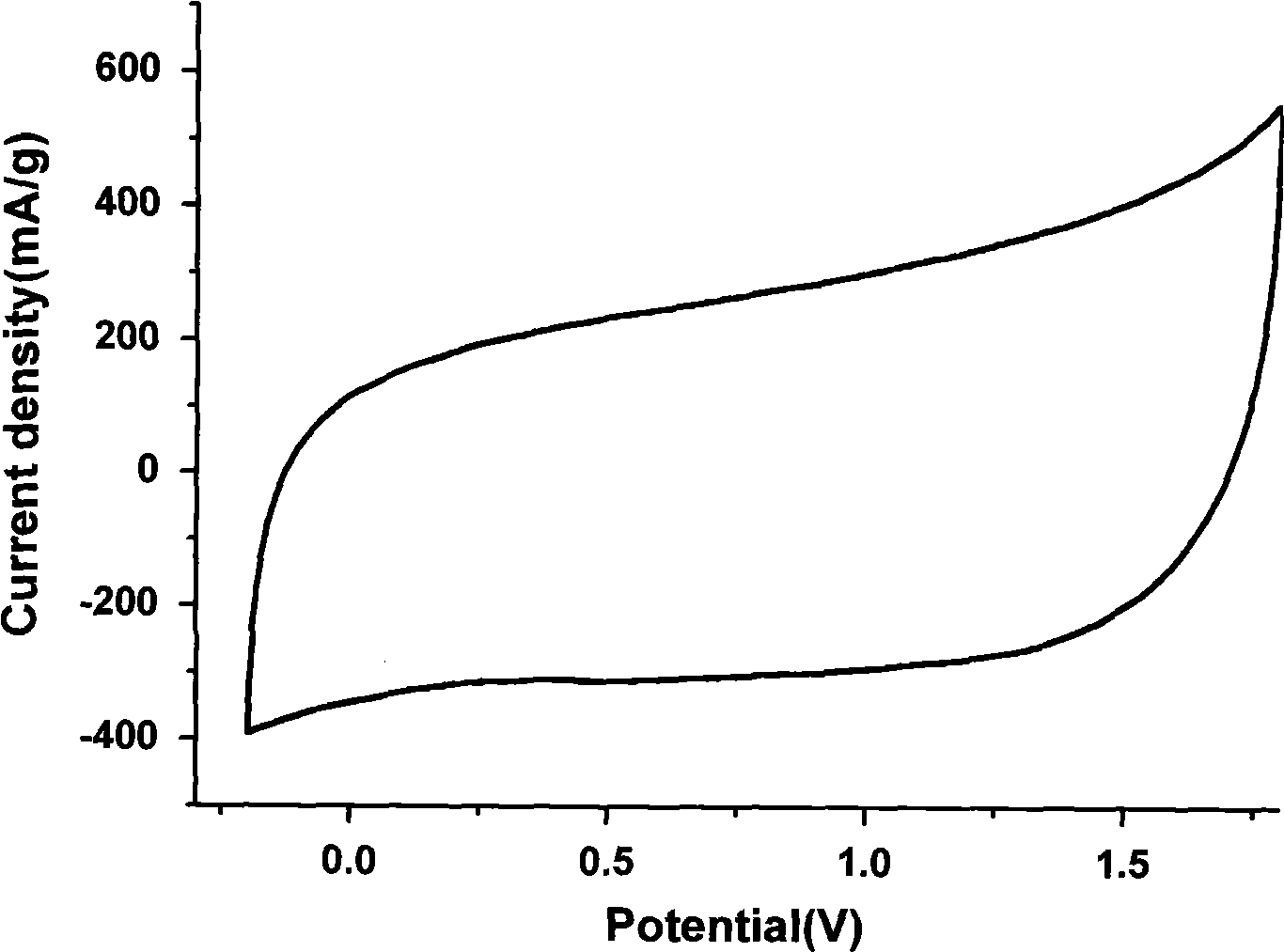

[0037] Stack the anod...

Embodiment 2

[0039] α-MnO Synthesized by Hydrothermal Method 2 , Weigh 1.0g of potassium permanganate and 0.42g of manganese sulfate in a flask, and keep stirring until the solution is clear. The solution was poured into a 150ml Teflon reaction kettle, sealed with stainless steel, and reacted at 160°C for 12h. The reactant was filtered, washed with ethanol or water, and the collected product was dried at 110°C, and the product α-MnO 2 The BET specific surface area is 51m 2 / g. α-MnO 2 , acetylene black and polytetrafluoroethylene by α-MnO 2 : Acetylene black: polytetrafluoroethylene = 70wt%: 20wt%: 10wt% mixed to form a manganese oxide anode;

[0040] Porous carbon and polytetrafluoroethylene are mixed according to porous carbon: polytetrafluoroethylene = 90wt%: 10wt% to form a porous carbon cathode, and the BET specific surface area of nitrogen-containing porous carbon is 2492m 2 / g;

[0041] Stack the anode, diaphragm and cathode in sequence to form a compact structure, inject e...

Embodiment 3

[0043] The operating method is the same as in Example 2, and the hydrothermal method synthesizes β-MnO 2, the difference is: Potassium permanganate weighed 0.28g, manganese sulfate weighed 0.90g, the reaction product β-MnO 2 The BET specific surface area is 10m 2 / g, the BET specific surface area of nitrogen-containing porous carbon is 2492m 2 / g. The operating voltage of the capacitor in this example is 2V, and the measured specific capacitance is 19F / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com