External loop air lift type membrane bioreactor

A membrane bioreactor, air stripping technology, applied in biochemical instruments, chemical methods for reacting liquids and gaseous media, biochemical equipment and methods, etc., can solve problems such as contamination, cell loss, etc. Improve, improve filtering performance, make full use of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

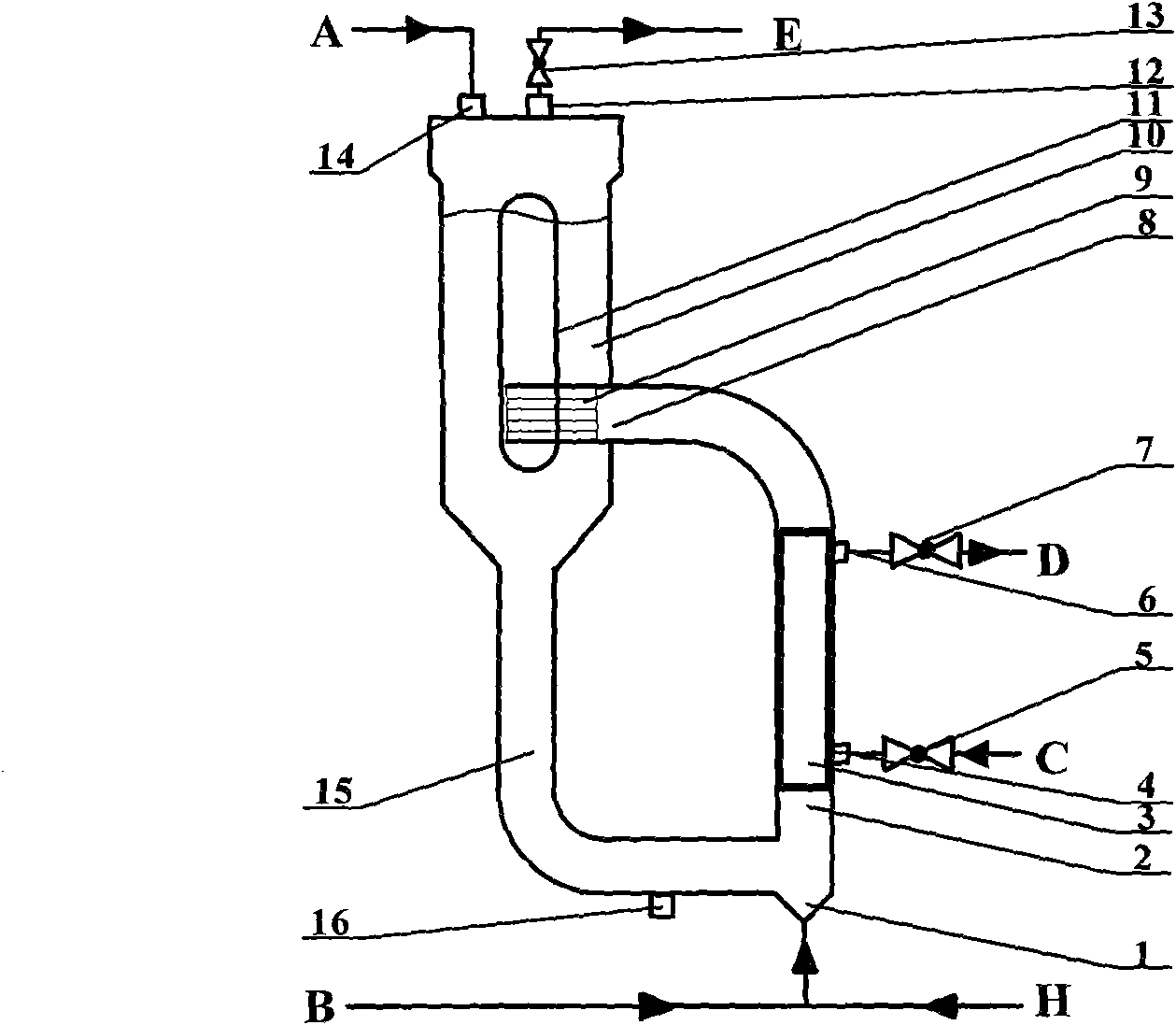

[0025] The outer circulation air-lift membrane bioreactor provided by the present invention is mainly composed of a reactor main body 10, a circulation pipeline 15, an air-lift tube 2, an aeration head 1, and an inorganic membrane element 3 encapsulated in the gas-lift tube. Air-lift return tube 8 , gas distributor 9 components, such as figure 1shown. The main body 10 of the reactor includes two parts, the shrinking section and the enlarged section. The inner diameter ratio of the two sections is determined by the ratio required for gas-liquid separation, which is about 1.5 to 8; the top of the main body 10 of the reactor is provided with a feed port 14 and an exhaust port 12 , A valve 13 is installed at the exhaust port to adjust the exhaust volume to adjust the pressure in the reactor. A pressure gauge is also installed on the top of the reactor to observe the pressure change of the reactor; there is a window on the reactor body for observing the reactor. The reaction pheno...

Embodiment 2

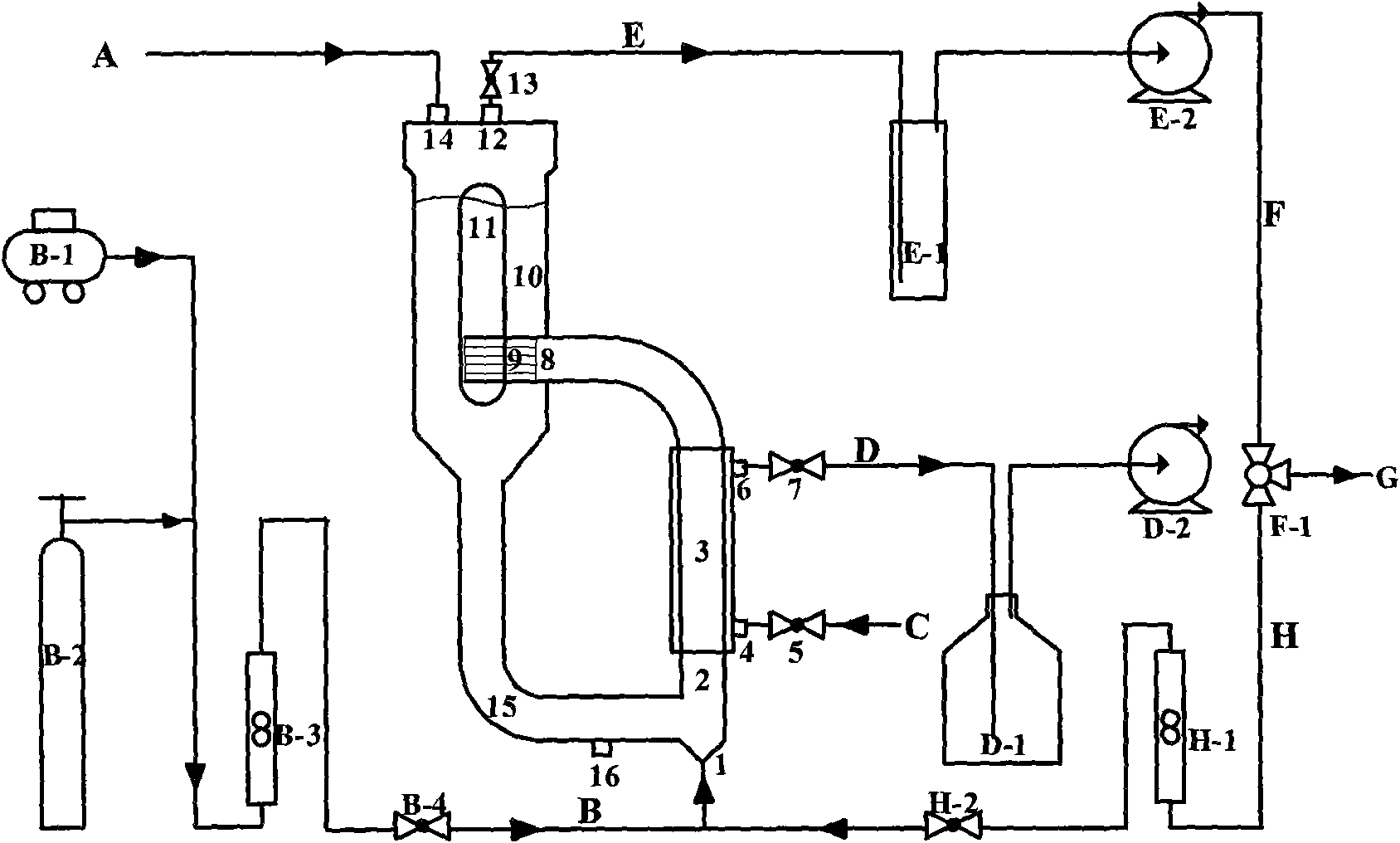

[0028] The system technology of the outer loop airlift type membrane bioreactor provided by the present invention is as follows figure 2 As shown, the details are as follows: feed liquid into the reactor through pipeline A, and blow compressed gas into it through pipeline B. The compressed gas is compressed air B-1 or cylinder-filled gas B-2, and the compressed gas passes through the flow meter B- 3 and valve B-4 control the measurement and enter the air lift pipe 2 through the aeration head 1. Driven by the compressed gas with initial velocity and the density difference, the liquid reaches the inorganic ceramic membrane separation unit 3 for microfiltration, and the valve 7 Controls whether to perform membrane separation. When the membrane separation is carried out under the pressure in the reactor or driven by the vacuum pump D-2, the valve 7 is opened, and the obtained filtrate is collected in the storage tank D-1. The concentrated solution continues to circulate through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com