Constant current driver of digital semiconductor laser

A technology for constant current drivers and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of poor performance of lasers, endangering the safe use of devices, and not seeing specific structures, etc., to improve output stability and protect safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

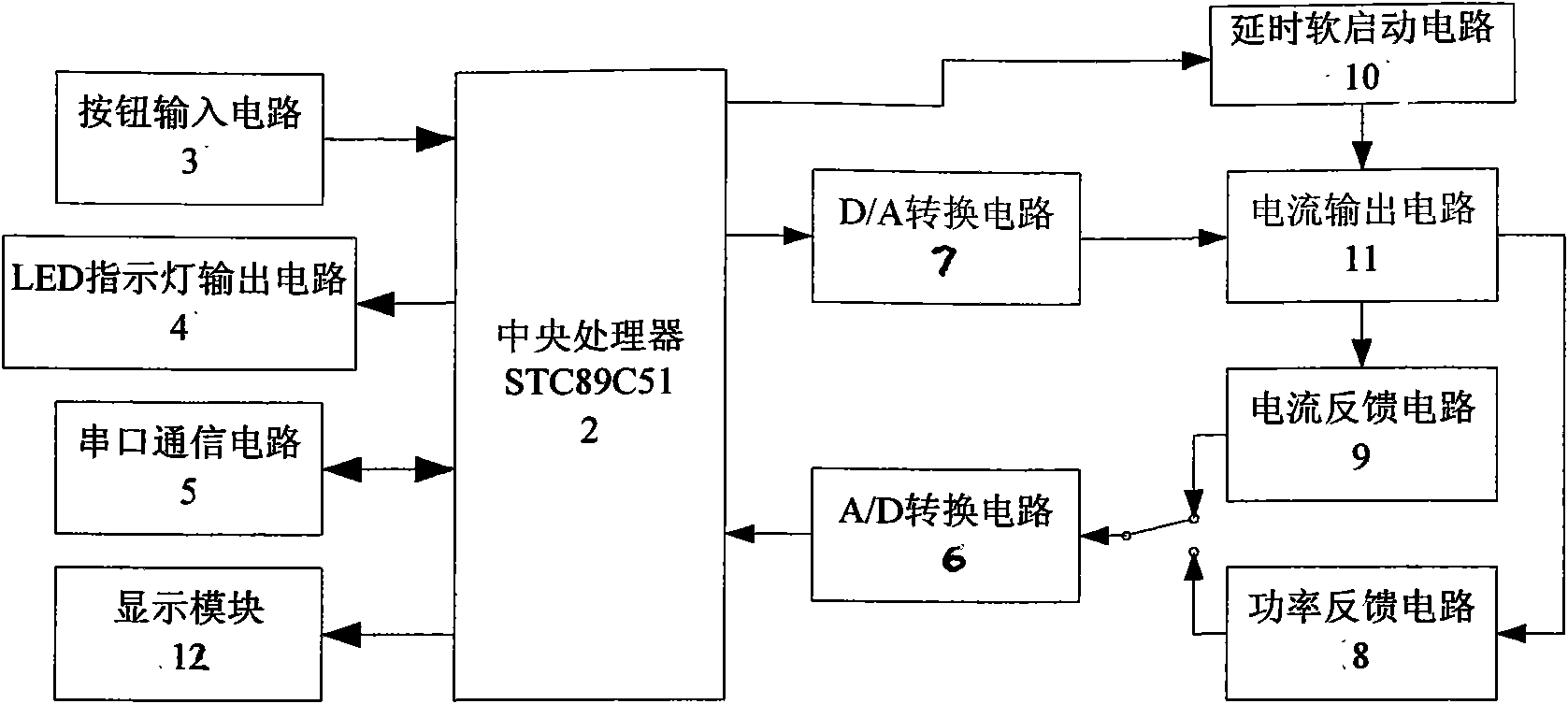

[0059] Example 1 combined figure 1 Explain the general structure of the present invention

[0060] Such as figure 1 As shown, the digital semiconductor laser constant current driver of the present invention consists of a front panel 1, a central processing unit 2, a button input circuit 3, an LED indicator light output circuit 4, a serial port communication circuit 5, an A / D conversion circuit 6, and a D / A The conversion circuit 7 , the power feedback circuit 8 , the current feedback circuit 9 , the delayed soft start circuit 10 , the current output circuit 11 and the display module 12 are composed.

[0061] The central processing unit 2 is composed of a STC89C51 single-chip microcomputer, and the STC89C51 provides the voltage value corresponding to the set current to the D / A conversion circuit 7 to convert it into an analog voltage, and then controls the current output circuit 11 to generate an output current. In order to ensure the stability of the output current, accordin...

Embodiment 2

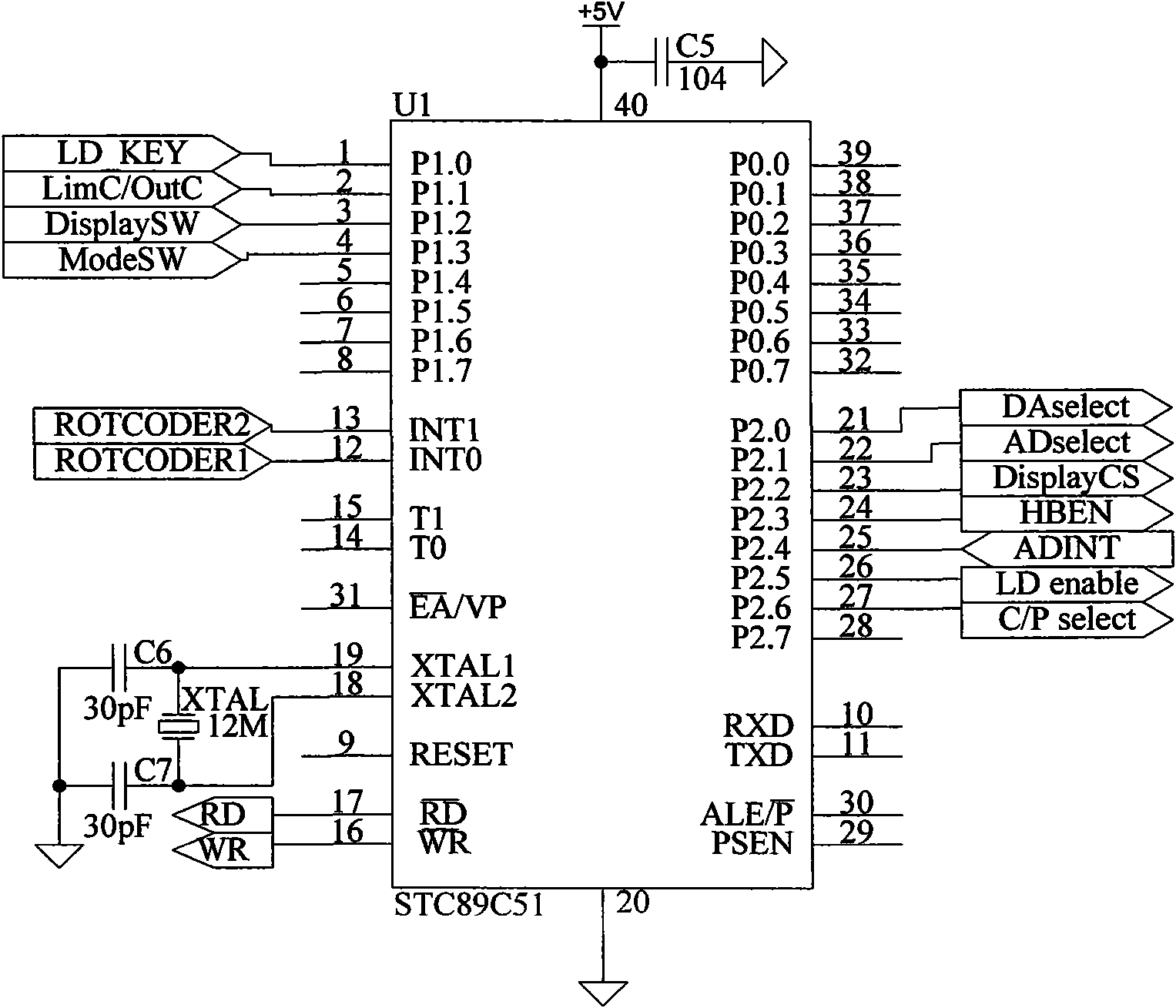

[0062] Embodiment 2 CPU 2

[0063] Such as figure 2 As shown, the central processing unit 2 is composed of STC89C51 single-chip microcomputer; the button input circuit 3 is connected with the INT0, INT1, P1.0, P1.1, P1.2 and P1.3 pins of the STC89C51 to provide the current button information for the central processing unit 2 Input state; LED indicator light output circuit 4 is connected with P1.4, P1.5, P1.6 and P1.7 pins of STC89C51, and the display state of LED indicator light output circuit 4 is controlled by central processing unit 2; display module 12 It is connected with P0.0, P0.1, P0.2, P0.3, P0.4, P0.5, P0.6 and P0.7 pins of STC89C51, and the display of the display module 12 is controlled by the central processing unit 2; The serial port communication circuit 5 is connected with the TXD and RXD pins of STC89C51, and communicates with the upper computer through the serial port communication circuit 5 . A / D conversion circuit 6 is connected with P0 port, P2.1, P2.3, ...

Embodiment 3

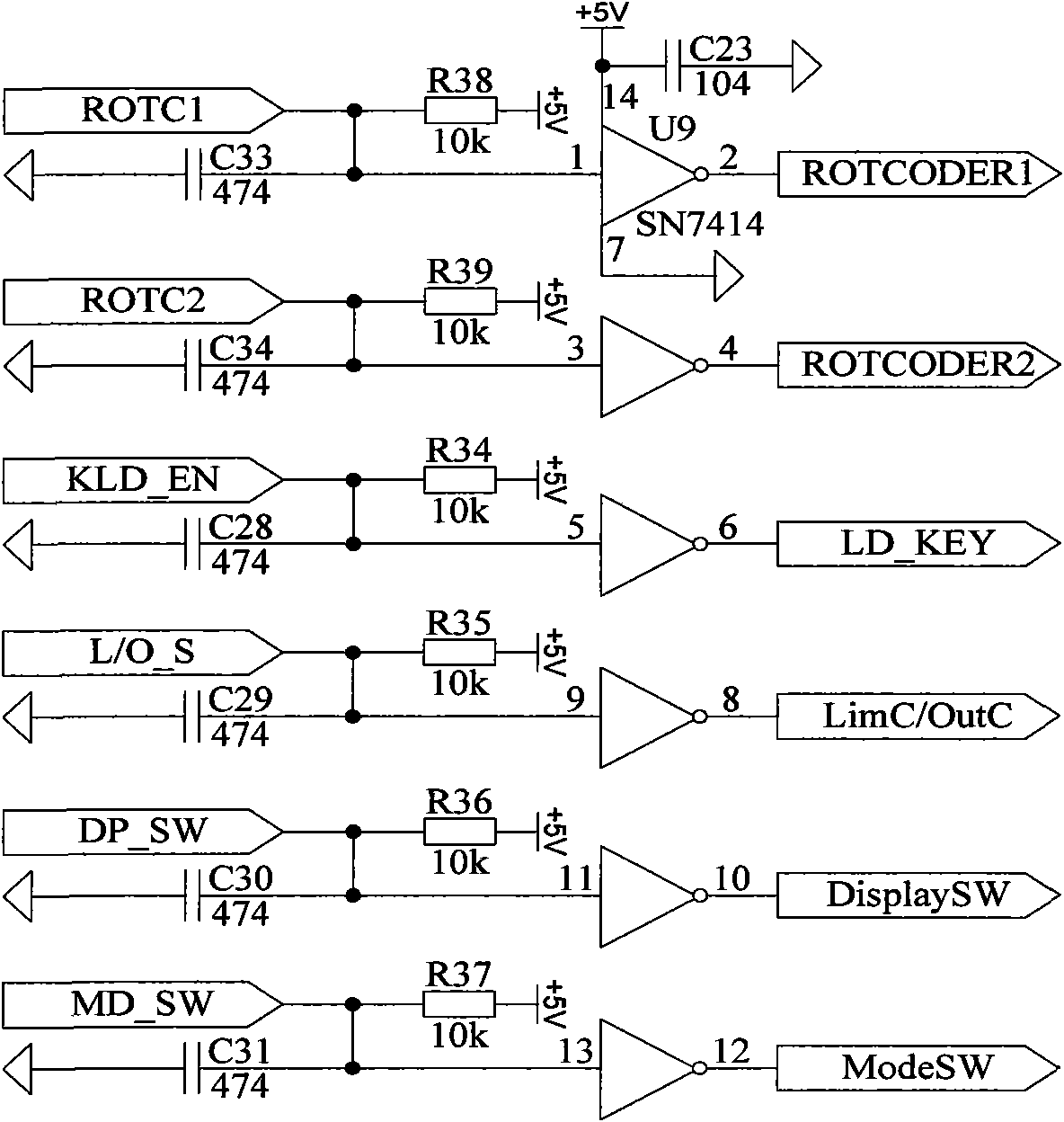

[0064] Embodiment 3 button input circuit 3

[0065] Such as image 3As shown, the button input circuit 3 includes: the 14th pin of the Schmitt trigger chip SN7414 is connected to the +5V power supply, and is grounded through the filter capacitor C32 (0.1uF); the 7th pin of the SN7414 is grounded; the 1st pin of the SN7414 is connected to the resistor R38 (10kΩ) is connected to +5V power supply, grounded through capacitor C33 (0.47uF), connected to port "ROTC1", which is pin 1 of the rotary encoder corresponding to the current adjustment knob on the front panel 1; pin 2 of SN7414 is connected to port "ROTCODER1 "That is, the external interrupt pin INT0 of the central processing unit STC89C51; the 3 pin of the SN7414 is connected to the +5V power supply through the resistor R39 (10kΩ), grounded through the capacitor C34 (0.47uF), and connected to the port "ROTC2", which is the current adjustment of the front panel 1 The 2 pins of the rotary encoder corresponding to the knob; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com