Fertilizer with biological ferment and preparation method and use method thereof

A bio-enzyme and fertilizer technology, applied in fertilizer mixture, application, fertilization device and other directions, can solve the problems of large amount of fermentation raw materials, unsuitable for large-scale promotion, expensive and other problems, and achieve the effect of promoting the formation of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 preparation has the fertilizer of biological ferment

[0041] First, commercially available Bacillus subtilis, yeast and actinomycetes were mixed according to the weight parts of Bacillus subtilis accounting for 60 parts, yeast accounting for 25 parts and actinomycetes accounting for 15 parts to obtain the strain of this embodiment.

[0042] The protein raw material is a mixture of corn flour, fish meal and shrimp meal, the amino acid raw material is a mixture of egg and plant dregs, and the water-soluble nitrogen, phosphorus and potassium, mineral raw materials and trace elements are all commercially available.

[0043] The fertilizer with biological ferment of the present embodiment, its specific preparation steps are as follows:

[0044] (1) Ferment protein raw materials, water-soluble nitrogen, phosphorus and potassium and strains (accounting for one thousandth of the total mass of protein raw materials and water-soluble nitrogen, phosphorus and potassi...

Embodiment 2

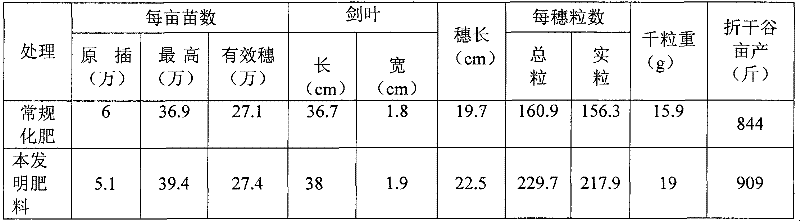

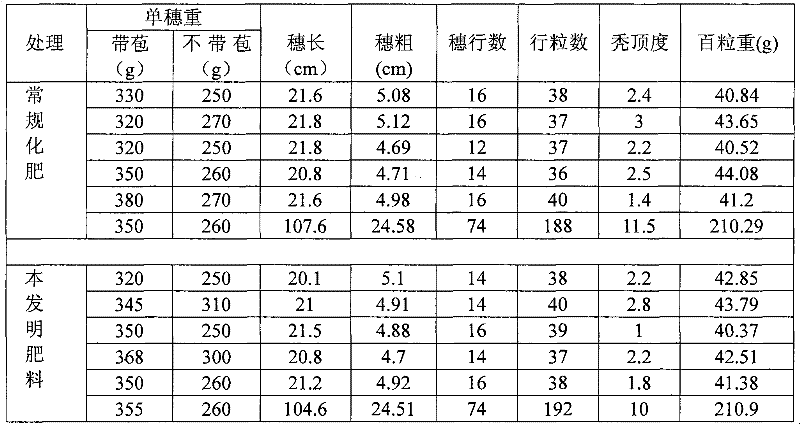

[0047] Example 2 Use of fertilizers with biological enzymes

[0048] Get the fertilizer with biological enzyme prepared by Example 1, and detect its application effect. First, buy a simple fermenter (or make one yourself) on the market, open the jar of adorned vitality agent, and put vitality into the fermenter. agent (dry powder), inject negative ionized filtered water, the volume of filtered water is about 3 / 5 of the volume of the fermenter, carry out the first fermentation, inflate for 8 hours a day, the inflated volume of 250W per ton, the temperature is 25 ℃, fermentation After 4 days, add negative ionized filtered water again, fill the entire fermenter, then open the jar containing the nutrient, put the nutrient (dry powder) into the fermenter, mix and carry out the second fermentation, inflate for 8 hours a day, every day The pumping capacity is 250W per ton, the temperature is 25°C, and after 16 days of fermentation, the obtained fermentation product is concentrated fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com