Process for continuous preparation of diisopropylbenzene dihydroperoxide

A technology of dicumyl dihydroperoxide and a preparation process is applied in the preparation of peroxy compounds, preparation of organic compounds, organic chemistry, etc., and can solve problems such as low production efficiency, long precipitation time, increased energy consumption, and the like, Achieve the effect of saving energy consumption, improving quality and purity, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A kind of continuous preparation process of dicumyl dihydroperoxide of the present invention, comprises the following steps:

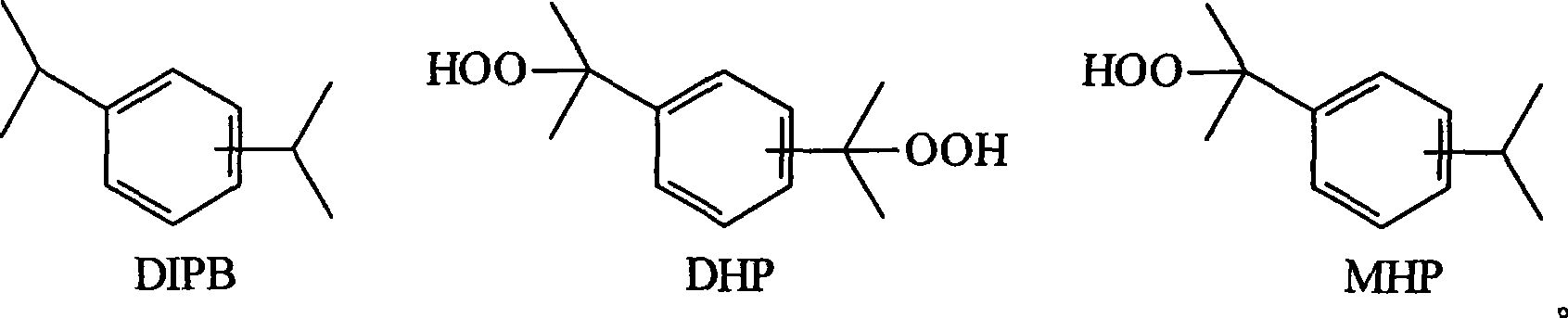

[0017] First drop into 430gDIPB in oxidation reactor as reaction raw material (the mass ratio of its middle dicumyl and p-dicumyl is 35: 65), then add 0.25g dibenzoyl peroxide, then be heated to 95 ℃ and Keep warm, feed compressed air at a flow rate of 90L / h for bubbling oxidation, keep the pressure of the reaction system at 0.45MPa during the reaction, and the reaction time is 14h; The liquid is analyzed by high-performance liquid chromatography (HPLC), and its main components (here, the component content is expressed by area percentage, the same below) include 3.9% DIPB, 60.7% DHP and 31.6% MHP;

[0018] The oxidation solution after the above oxidation reaction is sent into an extraction reactor equipped with 220g sodium hydroxide solution (mass concentration 15%), after stirring and extracting for 30min, the DHP in the oxidation solution is d...

Embodiment 2

[0020] A kind of continuous preparation process of dicumyl dihydroperoxide of the present invention, comprises the following steps:

[0021] First drop into 430gDIPB in oxidation reactor as reaction raw material (the weight ratio of middle dicumyl and p-dicumyl is 35:65), then add 1.2g dihydroperoxide dicumyl, then heat to 115 ℃ and heat preservation, and the flow rate of 70L / h is passed into the compressed air for bubbling oxidation. During the reaction, the pressure of the reaction system is kept at 0.45MPa, and the reaction time is 16h; Take the oxidized solution for HPLC analysis, its main components include 2.4% DIPB, 63.5% DHP and 28.7% MHP;

[0022] The oxidized solution after the above reaction is sent into an extraction reactor equipped with 260 g of sodium hydroxide solution (mass concentration is 20%), and after stirring and extracting for 30 minutes, the DHP in the oxidized solution is dissolved in the sodium hydroxide solution, and the unconverted DIPB and MHP ar...

Embodiment 3

[0024] A kind of continuous preparation process of dicumyl dihydroperoxide of the present invention, comprises the following steps:

[0025] First put 430g DIPB into the oxidation reactor as the reaction raw material (the weight ratio of m-dicumene and p-dicumene is 35:65), then add 1.3g of azobisisobutyronitrile, and then heat to 85°C And keep warm, pass into compressed air with the flow rate of 85L / h and carry out bubbling oxidation, keep the pressure of reaction system during the reaction process as 0.56MPa, and the reaction time is 18h; The oxidation solution was analyzed by HPLC, and its main components included 1.6% DIPB, 66.5% DHP and 28.1% MHP;

[0026] The oxidation solution after the above-mentioned oxidation reaction is sent into the extraction reactor that 300g sodium hydroxide solution (mass concentration is 18%) is housed, after stirring and extracting for 30 minutes, the DHP in the oxidation solution is dissolved in the sodium hydroxide solution, and does not T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com