Rigid polyurethane foam and preparation method thereof

A technology of rigid polyurethane and foamed plastics, applied in the field of rigid polyurethane foamed plastics and its preparation, capable of solving problems such as low thermal conductivity, low thermal conductivity, and destruction of the ozone layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

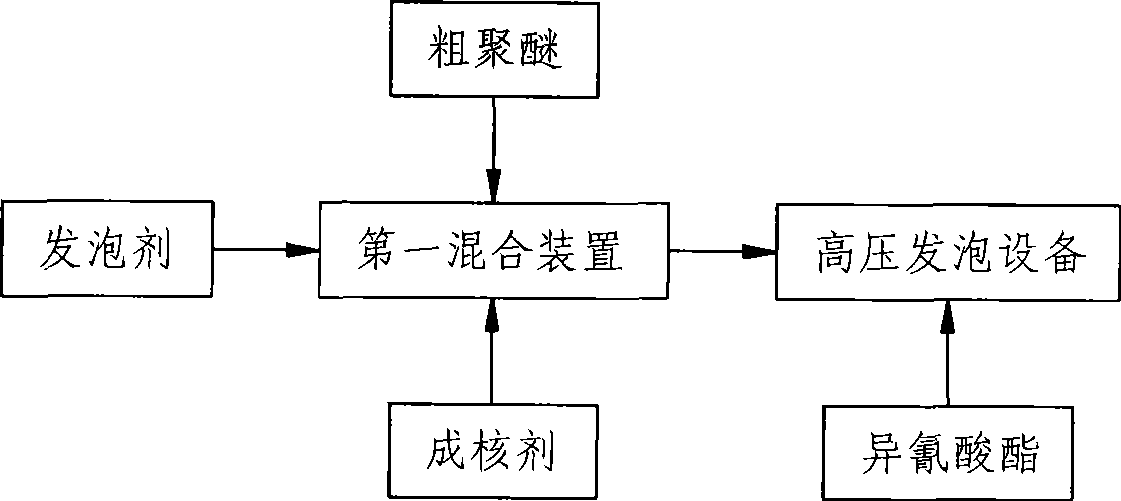

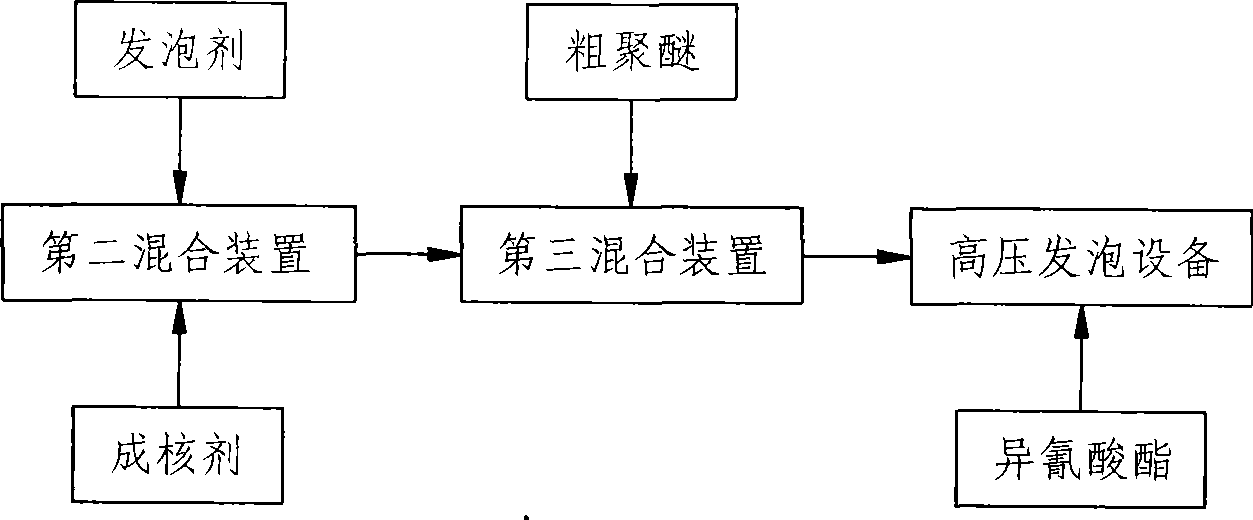

[0050] see Figure 1-Figure 2 , when this rigid polyurethane foam is made,

[0051] first plan

[0052] Step 1: Uniformly mix the foaming agent, nucleating agent and crude polyether through the first mixing device to obtain the first mixture; the first mixing device uses a pneumatic agitator with a rotating speed of 1500rpm-6000rpm, and the stirring time is 15 minutes to 60 minutes;

[0053]In the first mixture composed of foaming agent, nucleating agent and crude polyether, the mass percentages of foaming agent, nucleating agent and crude polyether in the total mass of the entire first mixture are: 1% to 12% , 9% to 29%, 70% to 90%;

[0054] Step 2, the above-mentioned first mixture is sent to high-pressure foaming equipment through the delivery pipeline, and the preparation of rigid polyurethane foam plastics is carried out with isocyanate accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com