Self circulation heat exchange method for materials in production of chlorinating paraffin-52 and chlorination reaction device therefor

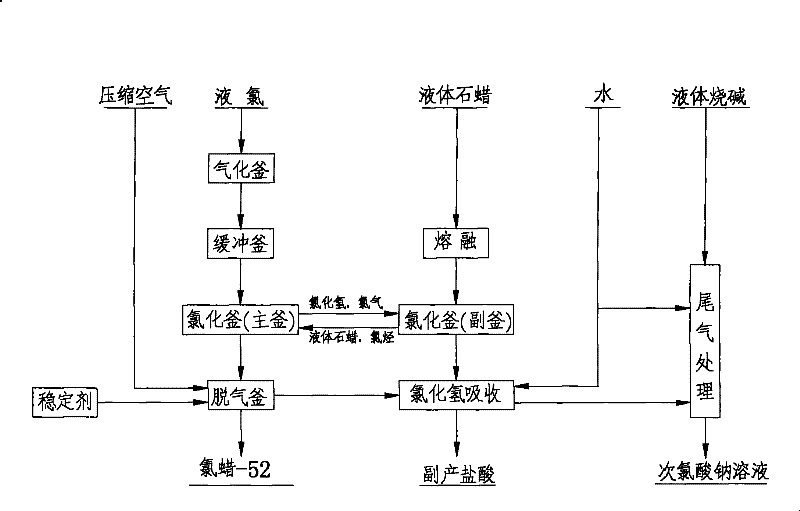

A technology of chlorinated paraffin and chlorinated reaction kettle, which is applied in the direction of petrochemical modification, etc., can solve the problems of limiting the reaction speed of chlorinated wax-52, increasing equipment investment and maintenance costs, affecting the quality of chlorinated wax-52, and eliminating Pollution and safety accidents, improving equipment utilization, and increasing the effect of chlorine intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

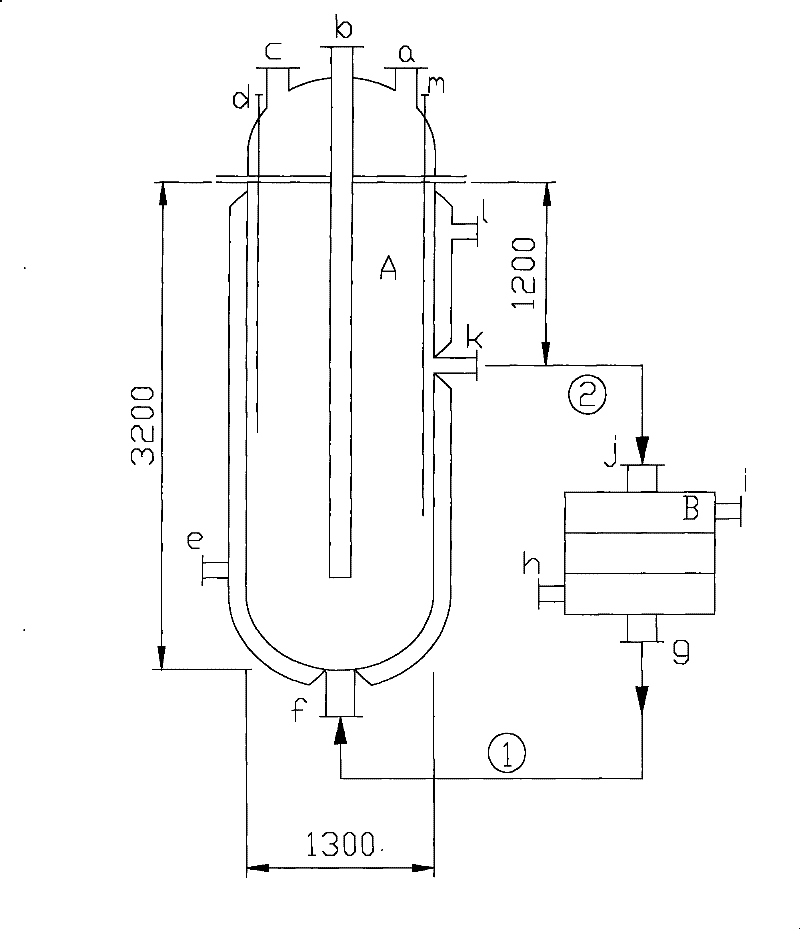

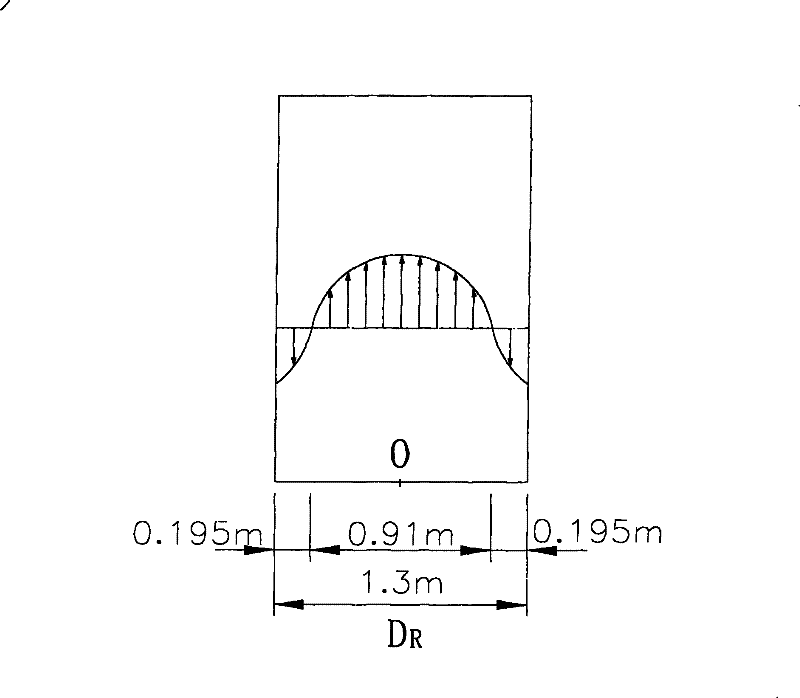

[0050] 1. Heat the liquid paraffin, raise the temperature to 80-90°C and let it stand for 1-8 hours. After the solid impurities settle, draw or pump the clarified liquid paraffin into the main and auxiliary chlorination reaction kettles (volume 4.15m 3 ), each kettle is 2500Kg, and the catalytic light source lamp in the kettle is turned on.

[0051] 2. After the liquid chlorine is vaporized in the gasification tank at 45°C, the pressure is stabilized by the buffer tank to stabilize the pressure at 130KPa (gauge pressure). The chlorine gas flow rate of 213Kg / h enters the main reactor through the chlorine pipe to chlorinate the liquid paraffin. Reaction, the chlorination reaction temperature is controlled at 105°C, the chlorination is about 24 hours, and when the chlorine content reaches 52%-54%, the reaction is stopped, and the crude product of chlorine wax-52 is pumped into the degassing kettle, and the air compressor is turned on. Blow compressed air to remove dissolved hydro...

Embodiment 2

[0054] Heat 2500kg of liquid paraffin, raise the temperature to 85°C and stand still for 4 hours, separate out 0.2kg of solid impurities and sediment, pump the clarified liquid into the chlorination reaction kettle (the kettle has a volume of 4.15m3), and turn on the catalytic light source lamp in the kettle.

[0055] The liquid chlorine passes through the gasification tank, and after being gasified at 45°C, the buffer tank stabilizes the pressure at 120KPa, and flows into the main tank of the chlorination tank at a flow rate of 230Kg / h to carry out the chlorination reaction. The temperature of the chlorination reaction is controlled at 105°C. After 24 hours, sample and analyze the chlorine content to 52.4%, stop the reaction, pump into the degasser, turn on the air compressor, blow off a small amount of hydrogen chloride and chlorine dissolved in the feed liquid with compressed air, add 10kg of stabilizer, and obtain chlorinated paraffin -52 products 5112kg. The tail gas comi...

Embodiment 3

[0057] Heat 2350kg of liquid paraffin, raise the temperature to 90°C and stand still for 2 hours, separate out 0.17kg of solid impurities and sediment, pump the clarified liquid into the chlorination reaction kettle (the kettle has a volume of 4.15m3), and turn on the catalytic light source lamp in the kettle.

[0058] The liquid chlorine passes through the gasification tank, and after being vaporized at 40°C, the pressure is stabilized at 100KPa through the buffer tank, and then passed into the main tank of the chlorination tank at a flow rate of 210Kg / h to carry out the chlorination reaction. The temperature of the chlorination reaction is controlled at 108°C. After 24 hours, sample and analyze the chlorine content to 51.53%, stop the reaction, pump into the degassing kettle, turn on the air compressor, blow off a small amount of hydrogen chloride and chlorine dissolved in the feed liquid with compressed air, add 9kg of stabilizer, and obtain chlorinated paraffin -52 product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com