Color cured composition, a color filter, a method for manufacturing the color filter and a liquid crystal display device

A technology of curable composition and color filter, which can be used in instruments, optical filters, nonlinear optics, etc., can solve the problems of undocumented coloring patterns, difficulty in forming high-precision coloring patterns, etc., and achieve the effect of excellent film strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0162] In preparation of the alkali-soluble resin, for example, a method by a known radical polymerization method can be employed. Various polymerization conditions such as temperature, pressure, the type and amount of the radical initiator, the type of solvent, etc. when preparing the alkali-soluble resin by the radical polymerization method can be easily set by those skilled in the art. Conditions can be determined experimentally.

[0163] As the linear organic high molecular polymer, a polymer having a carboxylic acid in a side chain is preferable. Can mention for example, in No. 59-44615, No. 54-34327, No. 58-12577, No. 54-25957, No. 59-53836, No. 59-71048 Methacrylic acid copolymers, acrylic acid copolymers, itaconic acid copolymers, crotonic acid copolymers, maleic acid copolymers, partially esterified maleic acid copolymers, etc. Acidic cellulose derivatives of acids, polymers obtained by addition of polymers having hydroxyl groups and acid anhydrides, etc., also incl...

Embodiment 1

[0336]

[0337] The components of the following composition were mixed, stirred and mixed with a homogenizer at a rotation speed of 3000 r.p.m. for 3 hours, and a mixed solution containing a pigment was prepared.

[0338] (composition)

[0339] ·Pigment Green 36 (average primary particle size is 25nm) 70 parts

[0340] ·Pigment Yellow 150 (average primary particle size is 25nm) 30 parts

[0341] ·Phthalocyanine derivatives 10 parts

[0342] (SOLSPERSE 3000, manufactured by Avecia Co., Ltd.)

[0343] ・75 parts of propylene glycol monomethyl ether acetate solution (solid content 40%) of benzyl methacrylate / methacrylic acid (=70 / 30 [molar ratio]) copolymer (Mw: 5,000)

[0344] · Dispersant (BYK-161, manufactured by BYK Company) 35 parts

[0345] ·Propylene glycol monomethyl ether acetate 495 parts

[0346] Next, the mixed solution obtained above was further subjected to a dispersion treatment for 6 hours with a bead disperser (dispermat) (manufactured by GETZMANN) using 0....

Embodiment 2

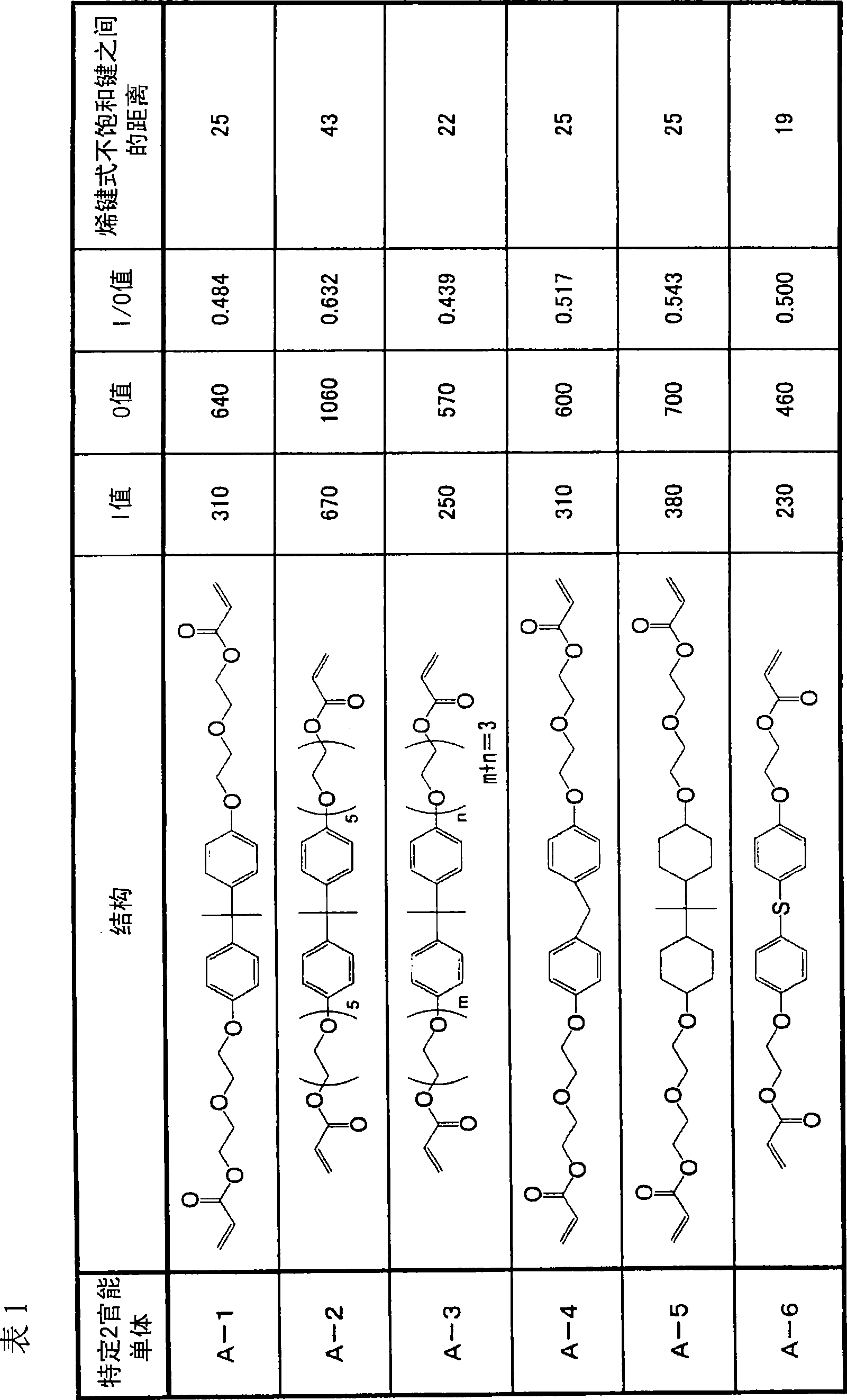

[0363] A colored curable composition was produced in the same manner as in Example 1, except that Exemplary Compound A-1, which was the specific bifunctional monomer used in Example 1, was replaced by Exemplary Compound A-2 described in Table 1 above. 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com