Preparation method of magnetic polymer inorganic composite micro-sphere

A technology of composite microspheres and polymers, which is applied in the field of preparation of magnetic polymer inorganic composite microspheres, can solve the problems of complex magnetic composite microspheres, achieve light density, simplify the process, and reduce the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

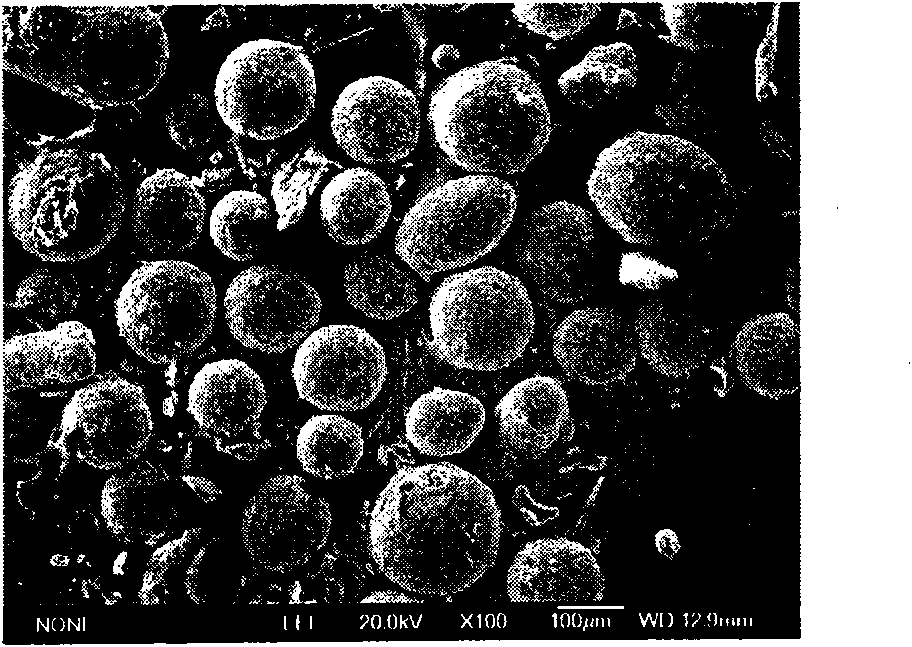

[0043] Embodiment 1 adopts ferric chloride to prepare porous magnetic powder:

[0044] Dissolve 13.5 g of ferric chloride in 100 g of water, add 50 g of 10 wt % sodium hydroxide solution, stir at room temperature for 30 min, and wash the obtained ferric hydroxide suspension with water three times. Pour the ferric hydroxide suspension into 100mL of 24wt% citric acid solution vigorously stirred at 70°C, then add 0.86g of barium carbonate and 6.49g of template n-butylamine, stir and evaporate at 75°C to make the solution into a viscous gel. After drying the viscous gel at 120°C, bake it at 550°C for 4 hours to remove the template agent and obtain porous magnetic powder.

[0045] The density of the obtained magnetic powder measured by the pycnometer method is 2.85g / cm 3 , the average pore diameter is 8.62nm.

Embodiment 2

[0046] Embodiment 2 adopts ferric nitrate to prepare porous magnetic powder:

[0047] Dissolve 20.2 g of ferric nitrate in 50 g of water, add 50 g of 10 wt % sodium hydroxide solution, stir at room temperature for 30 min, and wash the obtained ferric hydroxide suspension with water three times. Pour the ferric hydroxide suspension into 100mL of 24wt% citric acid solution vigorously stirred at 70°C, then add 0.86g of barium carbonate and 1.54g of template n-butylamine, stir and evaporate at 75°C to make the solution into a viscous gel. After drying the viscous gel at 120°C, bake it at 550°C for 4 hours to remove the template agent and obtain porous magnetic powder.

Embodiment 3

[0048] Embodiment 3 adopts ferric chloride to prepare porous magnetic powder:

[0049]Dissolve 13.5 g of ferric chloride in 50 g of water, add 50 g of 10 wt % sodium hydroxide solution, stir at room temperature for 30 min, and wash the obtained ferric hydroxide suspension with water three times. Pour the ferric hydroxide suspension into 100mL of 24wt% citric acid solution vigorously stirred at 70°C, then add 0.86g of barium carbonate and 4g of template agent hexamethylenediamine, stir and evaporate at 75°C to make the solution into a viscous gel. After drying the viscous gel at 120°C, bake it at 550°C for 4 hours to remove the template agent and obtain porous magnetic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com