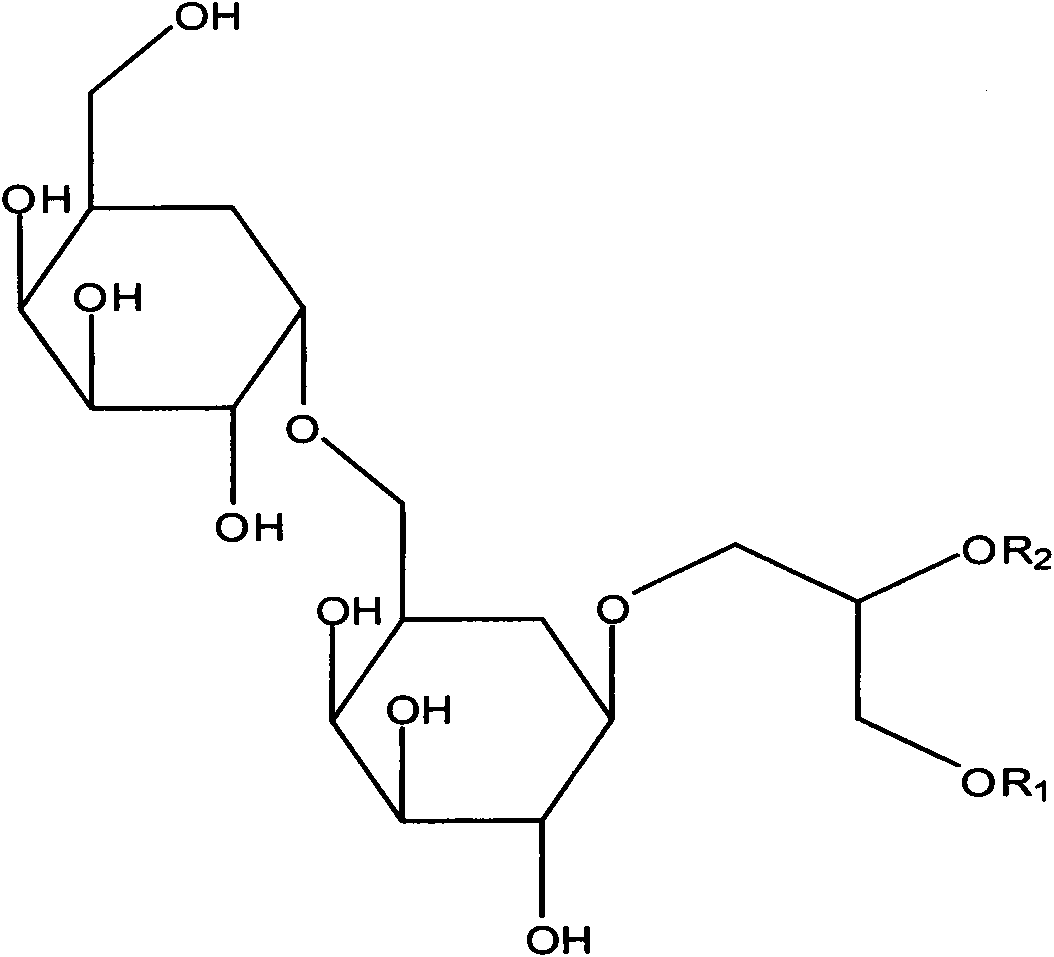

Preparation method for digalactosyl diacylglycerol (DGDG) and application thereof

A technology of lactosyl diacylglyceride and lactosyl diacylglycerol, which is applied in the field of preparation and application of medicinal natural surfactants, and can solve problems such as high cost, increased separation and purification, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

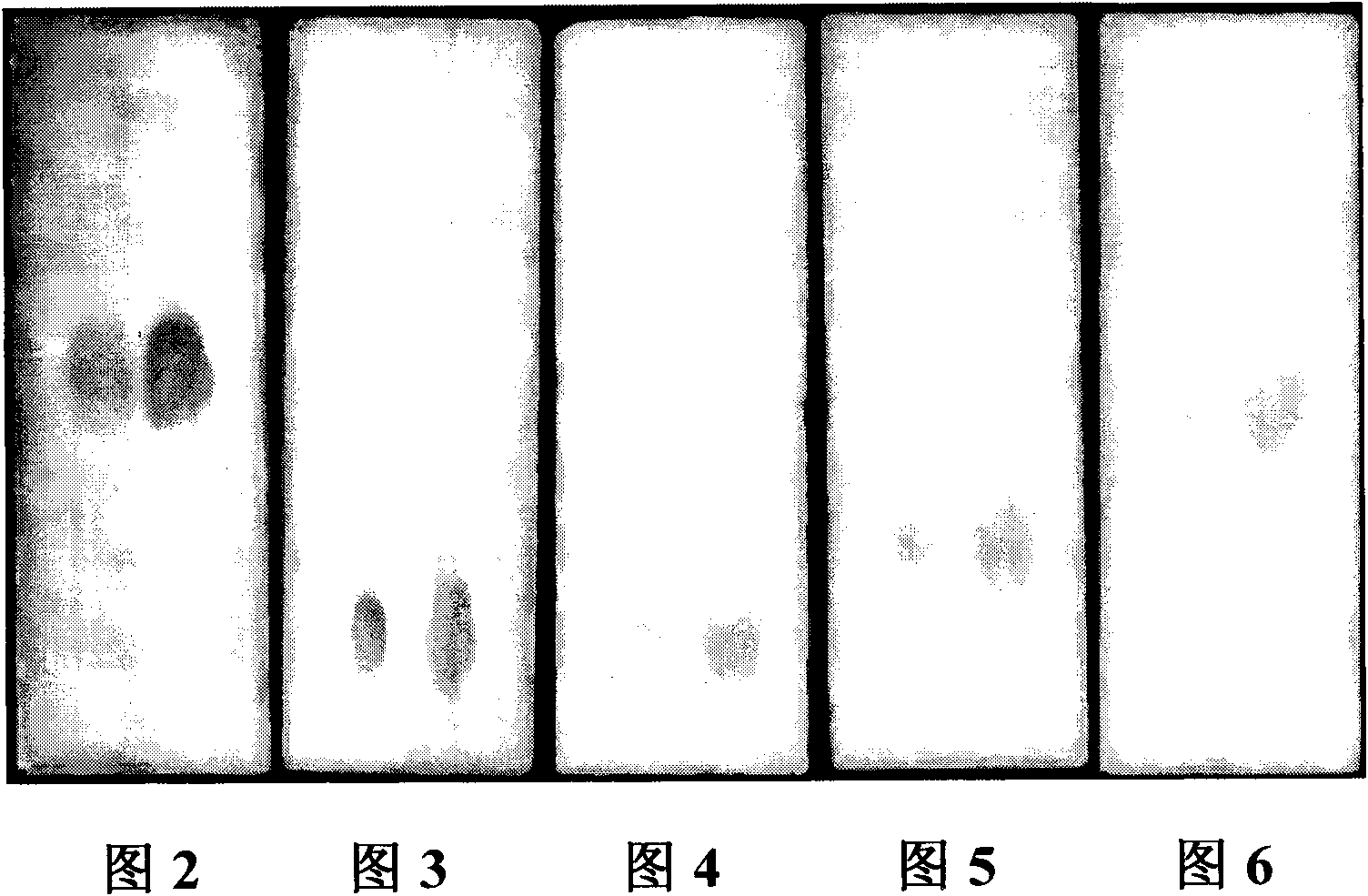

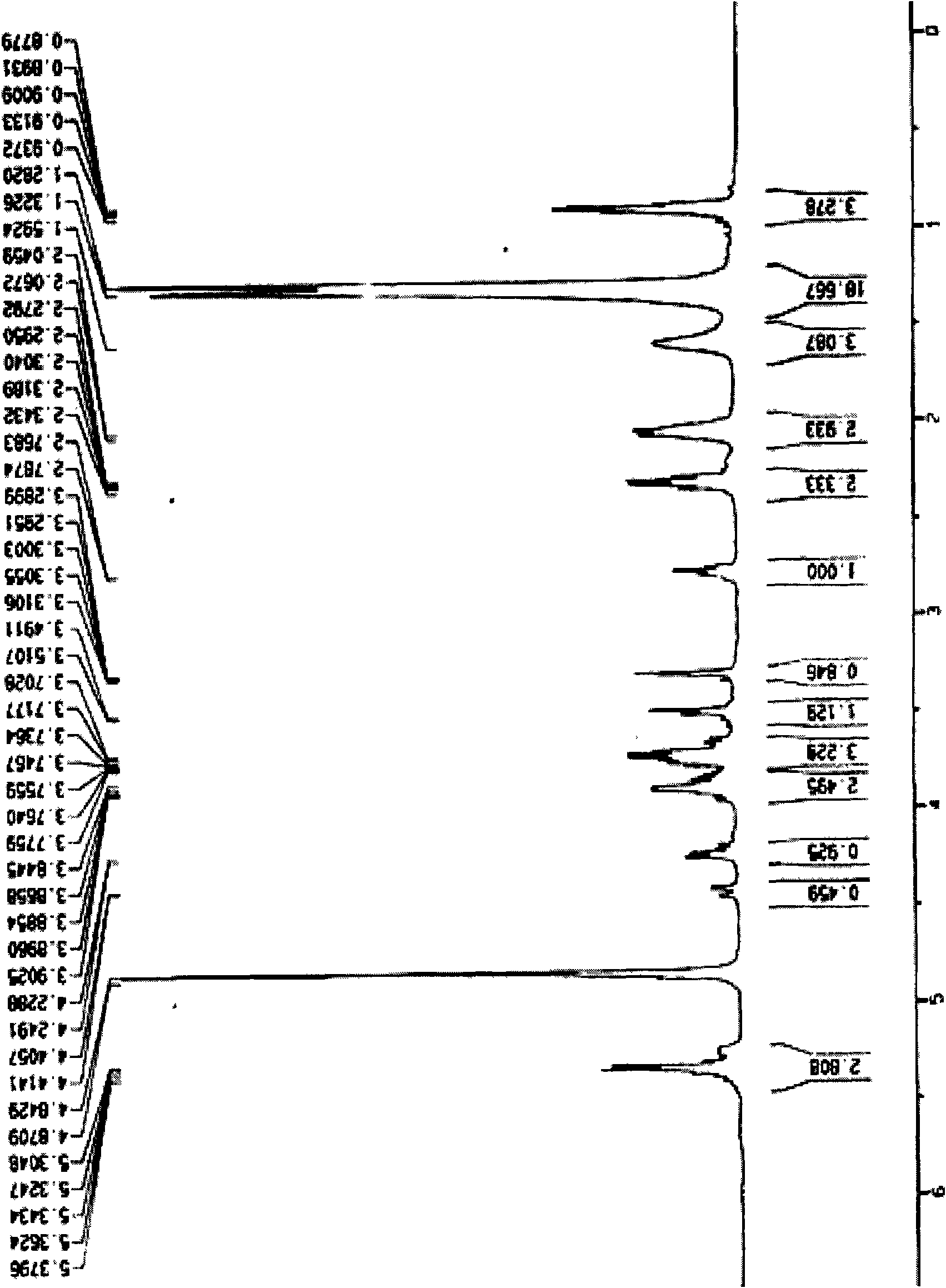

[0042]Embodiment 1: acetone extraction-silica gel column separation DGDG

[0043] Weigh 500 g of commercially available oat bran and add 1120 mL of acetone to extract at 56°C for 4 hours, extract 3 times, and combine the extracts from the 3 times. The extract was concentrated under reduced pressure at 50°C, the concentrated solution was mixed with 100 g of silica gel, and the solvent was evaporated to dryness. Add 110g of blank silica gel to the separation column, and then add the sample silica gel. First, 680 mL of cyclohexane-acetone 28:72 (v / v) mixture was used for elution, and finally 900 mL of acetone was used for elution. The acetone eluate was concentrated under reduced pressure at 47°C, the concentrate was mixed with 30 g of silica gel, and the solvent was evaporated to dryness. Add 100g of blank silica gel to the separation column, and then add the sample silica gel. First eluted with 650 mL of 85:15 (v / v) mixture of chloroform-methanol, and finally eluted with 680...

Embodiment 2

[0044] Embodiment 2: Carbon dioxide supercritical degreasing-extraction and separation of DGDG

[0045] Weigh 500g of commercially available oat bran, put it into the extraction kettle of the carbon dioxide supercritical extraction equipment, set the extraction pressure to 31MPa, the extraction temperature to 42°C, the temperature of the first separator to be 48°C, the temperature of the second separator to be 25°C, and the flow rate of the system to be Controlled at 75~78Kg·h -1 , take the extract from separator 1 every half hour, and extract for a total of 3 hours. The extracted oat bran was taken out, leached with 1200mL acetone at 50°C for 2.5 hours, leached 3 times, and the leached solutions were combined for 3 times. The extract was concentrated under reduced pressure at 45°C. The concentrated solution was mixed with 25g of silica gel, and the solvent was evaporated to dryness. Add 85g of blank silica gel to the separation column, and then add the sample silica gel. ...

Embodiment 3

[0046] Embodiment 3: the preparation of geranium oil DGDG submicron emulsion

[0047] Weigh 0.8g of DGDG, 2g of geranium oil, and 0.1g of sodium oleate, vortex and mix well, keep warm at 50°C, add 100mL (50°C) water for injection, stir until a uniform emulsion is formed, and cut it with a tissue homogenizer After cutting for 5 minutes, add high-pressure milk to homogenize at a pressure of 750 bar, homogenize 5 times, and the product is ready. The average particle size is 222.2nm, and the particle size distribution is narrow. See Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration (mass) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com