Method for preparing zirconium tungstate film

A technology of zirconium tungstate and thin film, which is applied in the direction of solid-state chemical plating, metal material coating process, coating, etc., can solve the problems of complex operation and high cost, and achieve the effect of simple equipment, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

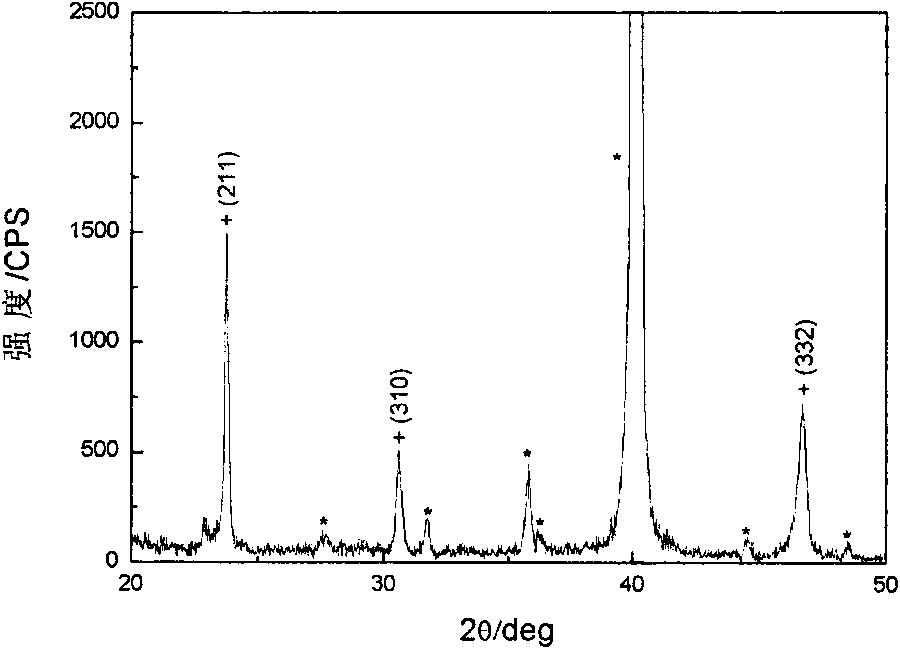

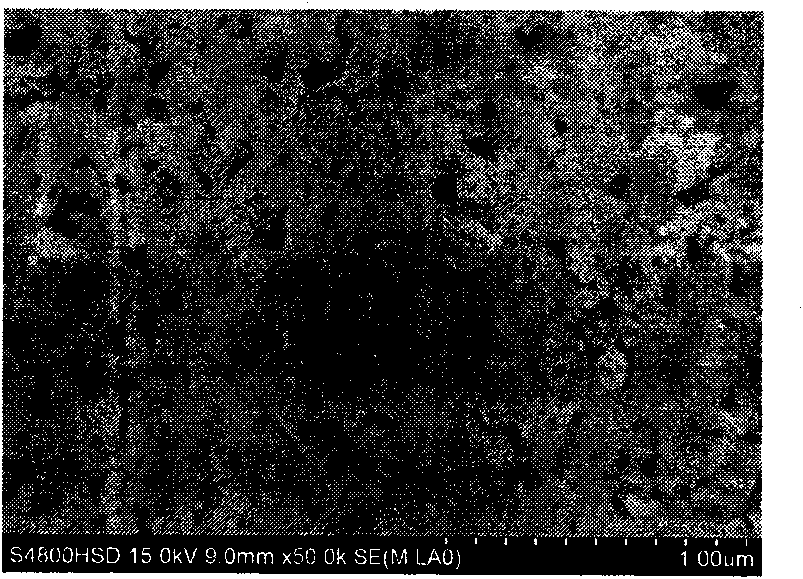

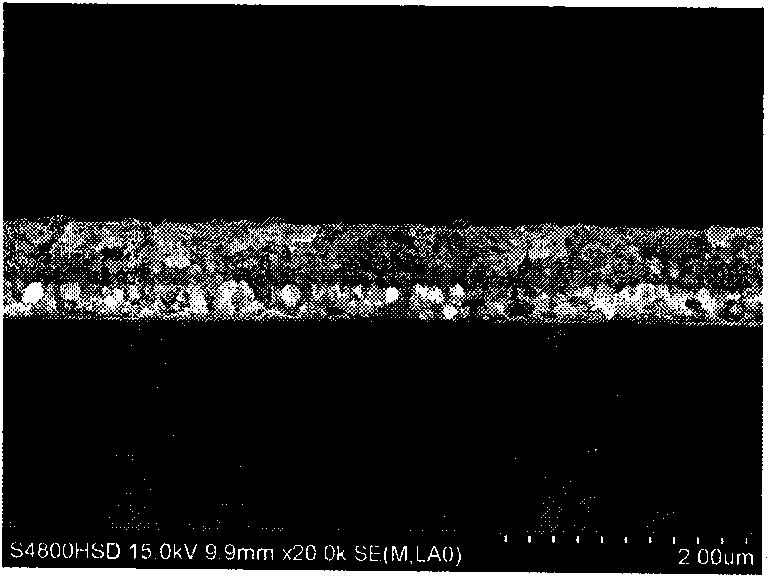

[0009] Specific Embodiment 1: The preparation method of zirconium tungstate film in this embodiment is carried out according to the following steps: 1. Add 0.82-1.92 g of zirconium oxynitrate to 5-15 mL of solvent, and stir at 50-80 °C for 5-10 minutes to obtain A solution; wherein the solvent is acetic acid, propanol, isopropanol, methanol, ethylene glycol, acetic acid or ethylene glycol methyl ether; 2. Mix 0.95-3.25g complexing agent, 15-25mL solvent and 1.15-3.92g Mix ammonium metatungstate evenly to obtain solution B, in which the complexing agent is citric acid, ethylenediaminetetraacetic acid or oxalic acid, and the solvent is acetic acid, propanol, isopropanol, methanol, ethylene glycol, acetic acid or ethylene glycol methyl ether 3. Mix A solution and B solution evenly, and age at 35-60°C for 1-3 days to obtain a sol; 4. Add the sol prepared in step 3 onto the substrate dropwise. Add 0.02-0.08mL of sol dropwise, and spin-coat at 3000-4000r / min for 5-15s to obtain a we...

specific Embodiment approach 2

[0011] Embodiment 2: This embodiment differs from Embodiment 1 in that in Step 1, 1-1.6 g of zirconyl nitrate is added to 7-13 mL of solvent. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0012] Embodiment 3: This embodiment is different from Embodiment 1 in that in step 1, 1.5 g of zirconyl nitrate is added to 10 mL of solvent. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com