Artificial trachea cannula with nanometre anti-microbial coating

A nano-antibacterial material and artificial trachea technology, applied in the field of medical devices, can solve the problems of inability to obtain satisfactory antibacterial effects, single antibacterial components, etc., and achieve the effects of simple and controllable manufacturing process, low dosage, and improvement of infection conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

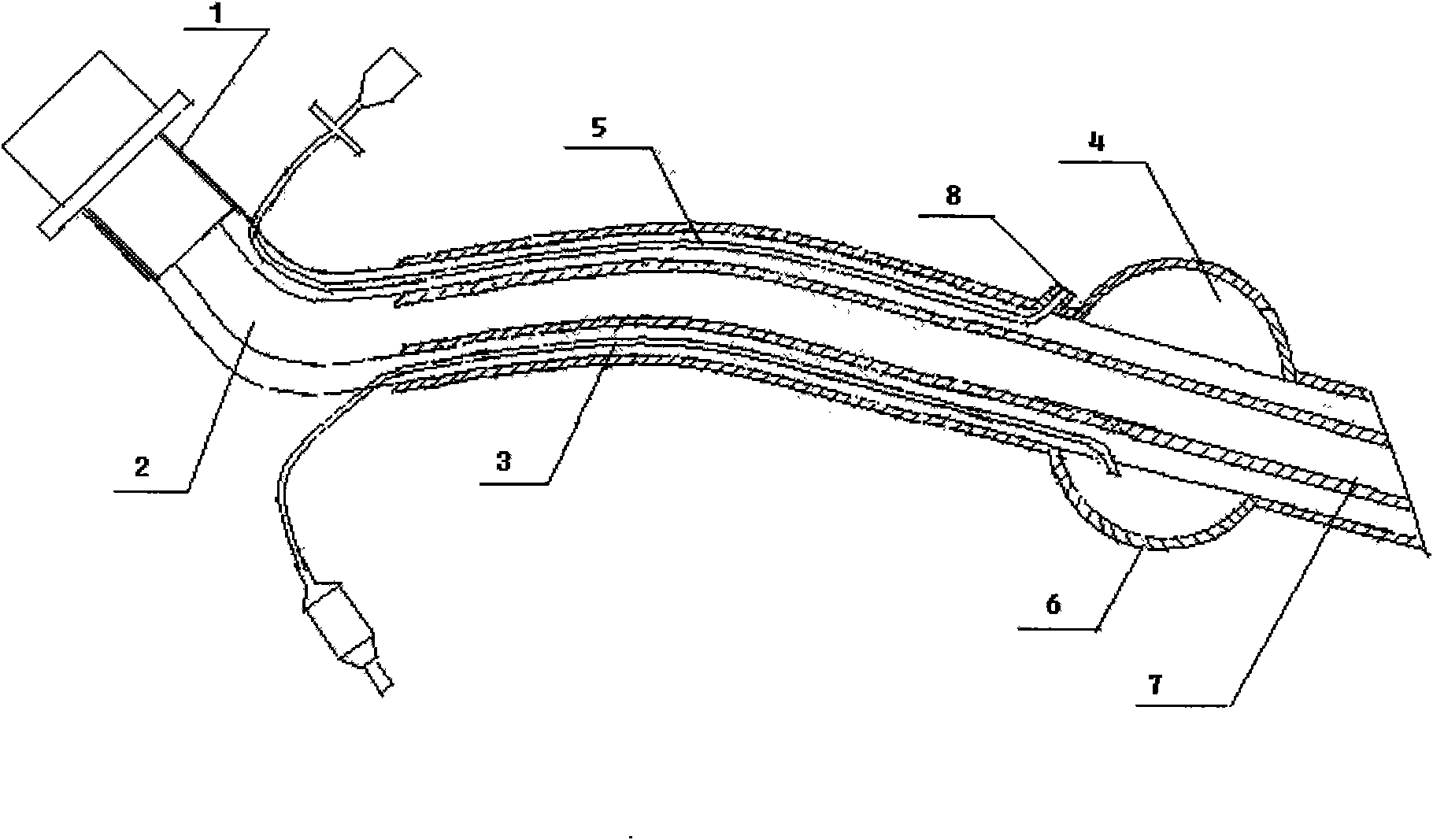

[0026] An artificial tracheal intubation tube, including a trachea 2, an inflatable tube 3 and an inflatable air bag 4, the trachea body has a connecting end 1 and an insertion end 7, the trachea connection end 1 is connected to a ventilator, and the trachea insertion end 7 It is wedge-shaped for easy insertion into the trachea; the inflatable airbag 4 is set on the outer surface of the insertion end 7 of the trachea, and the edge of the inflatable airbag is airtightly connected with the tube body of the trachea; It communicates with the inflatable airbag and is used to inflate the inflatable airbag 4; the other side of the trachea is embedded with a drain pipe 5, one end of the drain pipe has a liquid discharge port 8 above the inflatable airbag, and the other end can be connected with devices such as syringes , used to regularly suck out the liquid accumulated on the air bag.

[0027] The tracheal intubation is prepared by the extrusion molding process of medical grade polyv...

Embodiment 2

[0029] Polyvinylpyrrolidone (PVP) 5g (Tianjin Boai Xinkaikai Co., Ltd.), moxifloxacin 0.05g (Shenzhen Haibin Pharmaceutical Company), and nanoscale zeolite silver-loaded antibacterial agent 0.15g (Shanghai Bonaweilai New Material Technology Co., Ltd.) Co., Ltd.), 100ml of ethanol, 30ml of dimethylformamide, 30ml of ethyl acetate, mix well, and make a mixed solution for later use;

[0030] Immerse the artificial endotracheal tube prepared above according to the method of Example 1 in the mixed solution for 0.5 minutes, take it out, and dry it at 60-70° C. for about 5-10 minutes to obtain an artificial endotracheal tube with nano-antibacterial material coating. The thickness of the coating was on average 0.3 mm.

Embodiment 3

[0032] With polymer material PVP-vinyl acetate polymer 8.5g (Tianjin Boai Xinkaikai Co., Ltd.), piperacillin / tazobactam composite preparation 0.17g (Dalian Pfizer Company), nanoscale zirconium phosphate silver-loaded antibacterial agent 0.4 g (Shanghai Bona Weilai New Material Technology Co., Ltd.), 100ml of ethanol, 40ml of dimethylformamide, 30ml of ethyl acetate, 10ml of acetone, mix well, and make a solution for later use;

[0033] Immerse the artificial endotracheal tube prepared above according to the method of Example 1 in the mixed solution for 1 minute, take it out, and dry it at 60-70° C. for about 5-10 minutes to obtain an artificial endotracheal tube with nano-antibacterial material coating. The thickness of the coating was on average 0.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com