Carbon-spinel magnesium fire-resistant castable wrapped with nano Al2O3 and MgO films and preparation method thereof

A refractory castable and film wrapping technology, which is applied in the field of refractory materials, can solve the problems of inability to implement integral casting, affect the production of steel casting, and cannot be carried out at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

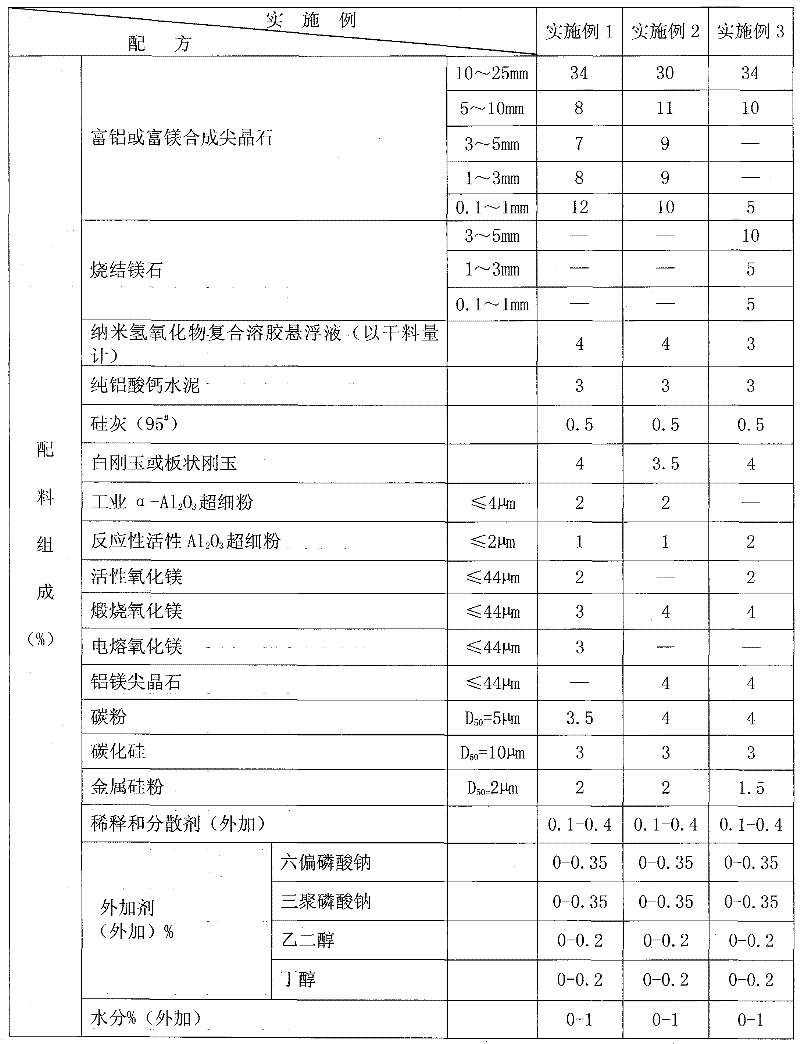

Embodiment 1

[0047] According to the present invention, be listed in the total reaction synthesis nano-Al of table 1 embodiment 1 2 o 3 Formula of carbon-spinel magnesia refractory castable with carbon powder wrapped in MgO film, add the mixture to the forced mixer for 1-2 minutes and dry mix it for 1-2 minutes, and then process the concentration of 58-61% after high-speed impact stirring The carbon-aluminum hydroxide mixed sol suspension is directly added to the mixture, and then wet mixed for 5 minutes. During the wet mixing process, 0-1% water is added according to the actual water demand of the mixture, and the mixture The active magnesium oxide powder and mixed water undergo hydration reaction at room temperature to generate magnesium hydroxide sol solution. These two composite sol suspensions are strongly adsorbed on the surface of the carbon powder through the combination and adsorption of the sol. A full-coverage, crack-free, and dense carbon coating is formed, and during the tran...

Embodiment 2

[0050]According to the non-total reaction synthesis (that is, adding part of the pre-synthesized spinel) carbon-spinel magnesia castable formula listed in Table 1 according to the present invention, the mixture is added to the forced mixer for dry mixing 1-2 minutes, then directly add the carbon-aluminum hydroxide composite sol suspension with a concentration of 58-61% treated by high-speed impact stirring into the mixture, and then wet-mix for 5 minutes. During the wet-mixing process, Add 0-1% water according to the actual water demand of the mixture, and make the active magnesium oxide powder in the mixture and the mixed water undergo hydration reaction at normal temperature to generate magnesium hydroxide sol, this composite sol suspension, Through the combination and adsorption of sol, it is strongly adsorbed on the surface of carbon, forming a full-coverage, crack-free, dense carbon coating. During the transformation process from sol to gel, nano-Al 2 o 3 and MgO gel par...

Embodiment 3

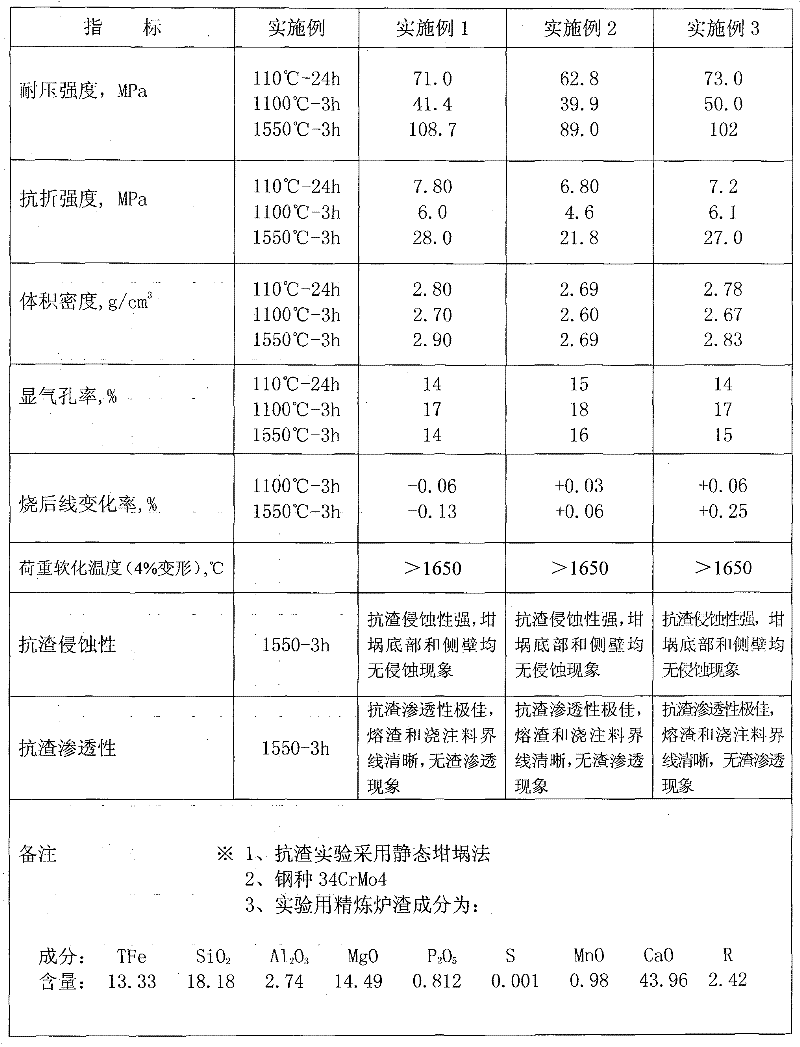

[0053] According to the present invention listed in the embodiment 3 of table 1 with nanometer Al 2 o 3 The carbon-spinel magnesia refractory castable formula wrapped with MgO film is mixed and stirred by a forced mixer, shaken by a vibrating table or a vibrating rod, and made into a prefabricated component of a certain size and single weight according to the actual situation. After air curing After 24 hours, bake in an electric heating oven at a temperature of 280°C for 80-120 hours, and then install the prefabricated components on the site of use (such as the slag line) in an assembled form. Compared with direct casting on site, this prefabricated structure has the following characteristics: first, it can better ensure the construction quality of castables; Third, the use of this prefabricated structure is conducive to the production of an anti-oxidation layer on the outer surface of the prefabricated components. The main technical performance indicators of the large-scale...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com