High-strength fiber glass reinforced ABS composite material and preparation method thereof

A composite material and high-strength glass fiber technology, which is applied in the field of high-strength glass fiber reinforced ABS composite materials and its preparation, can solve problems affecting the surface quality of parts, poor interface bonding, and floating fibers, etc., and is suitable for large-scale promotion and application. Good processing performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

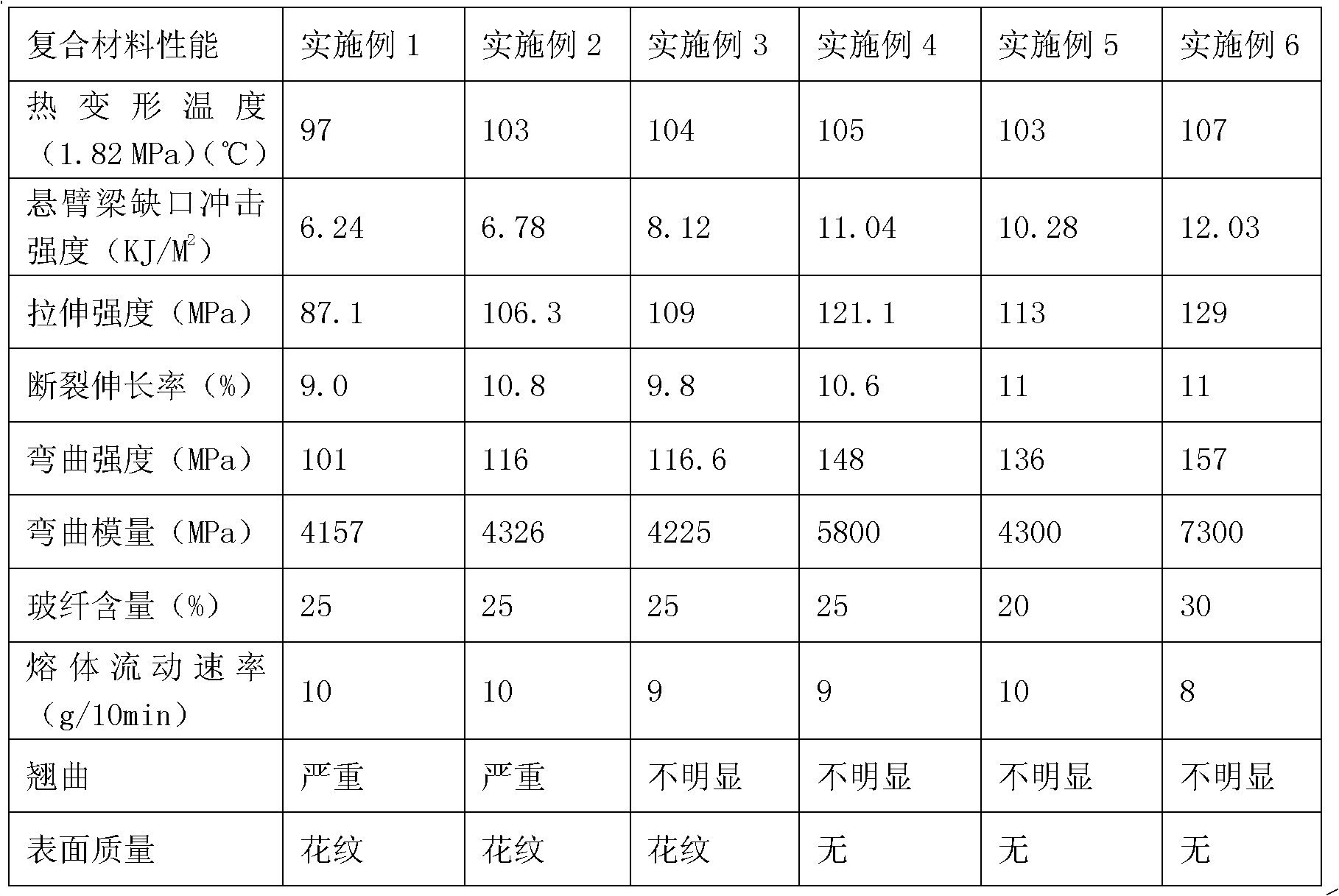

Examples

Embodiment 1

[0019] Example 1: ABS (brand PA757) 75kg, glass fiber (brand 988) 25kg.

[0020] Raw material pretreatment: ABS is dried in a vacuum drying oven at 80°C for 10 hours, and the glass fiber is dried in an oven at 100-120°C for 4 hours, cooled to room temperature for use.

[0021] Extruding and granulating on the same-rotating twin-screw extruder (the main engine screw speed is 200r / min, and the temperature of 1 to 7 stages is 205℃, 210℃, 215℃, 220℃, 225℃, 230℃, 225℃), The glass fiber is added from the glass fiber mouth. The pellets were dried at 80°C for 5 hours, and then injection molded on an injection molding machine to prepare a glass fiber reinforced ABS composite material.

Embodiment 2

[0022] Example 2: ABS (brand PA757) 71kg, glass fiber (brand 988) 25kg, SMA (brand 218) 4kg.

[0023] Raw material pretreatment: ABS and SMA are dried in a vacuum drying oven at 80°C for 10 hours, and the glass fiber is dried in an oven at 100-120°C for 4 hours, cooled to room temperature for use.

[0024] The dried ABS and SMA are mixed uniformly in a high-speed mixer, and then extruded and pelletized on the same-rotating twin-screw extruder (the main machine screw speed is 200r / min, and the temperature of stage 1 to 7 is 205℃, 210℃, 215 respectively. ℃, 220℃, 225℃, 230℃, 225℃), the glass fiber is added from the glass fiber mouth. The pellets were dried at 80°C for 5 hours, and then injection molded on an injection molding machine to prepare a glass fiber reinforced ABS composite material.

Embodiment 3

[0025] Example 3: ABS (brand PA757) 71kg, glass fiber (brand 988) 25kg, epoxy resin (brand CYD-011) 4kg, polymerization inhibitor (hydroquinone) 0.9kg.

[0026] Raw material pretreatment: ABS is dried in a vacuum drying oven at 80°C for 10 hours, and the glass fiber is dried in an oven at 100-120°C for 4 hours, cooled to room temperature for use.

[0027] The dried ABS, epoxy resin and hydroquinone are mixed uniformly in a high-speed mixer, and extruded and pelletized on the same rotating twin-screw extruder (the main machine screw speed is 200r / min, and the temperature of 1 to 7 stages is respectively 205°C, 210°C, 215°C, 220°C, 225°C, 230°C, 225°C), the glass fiber is added from the glass fiber port. The pellets were dried at 80°C for 5 hours, and then injection molded on an injection molding machine to prepare a glass fiber reinforced ABS composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com