Method for separating and extracting L-arabinose from waste wood sugar mother liquid from wood sugar production

A technology of xylose mother liquor and arabinose, applied in the field of separation and extraction of L-arabinose, which can solve the problems of unfriendly environment and high production cost, and achieve the effects of no environmental pollution, less energy consumption and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

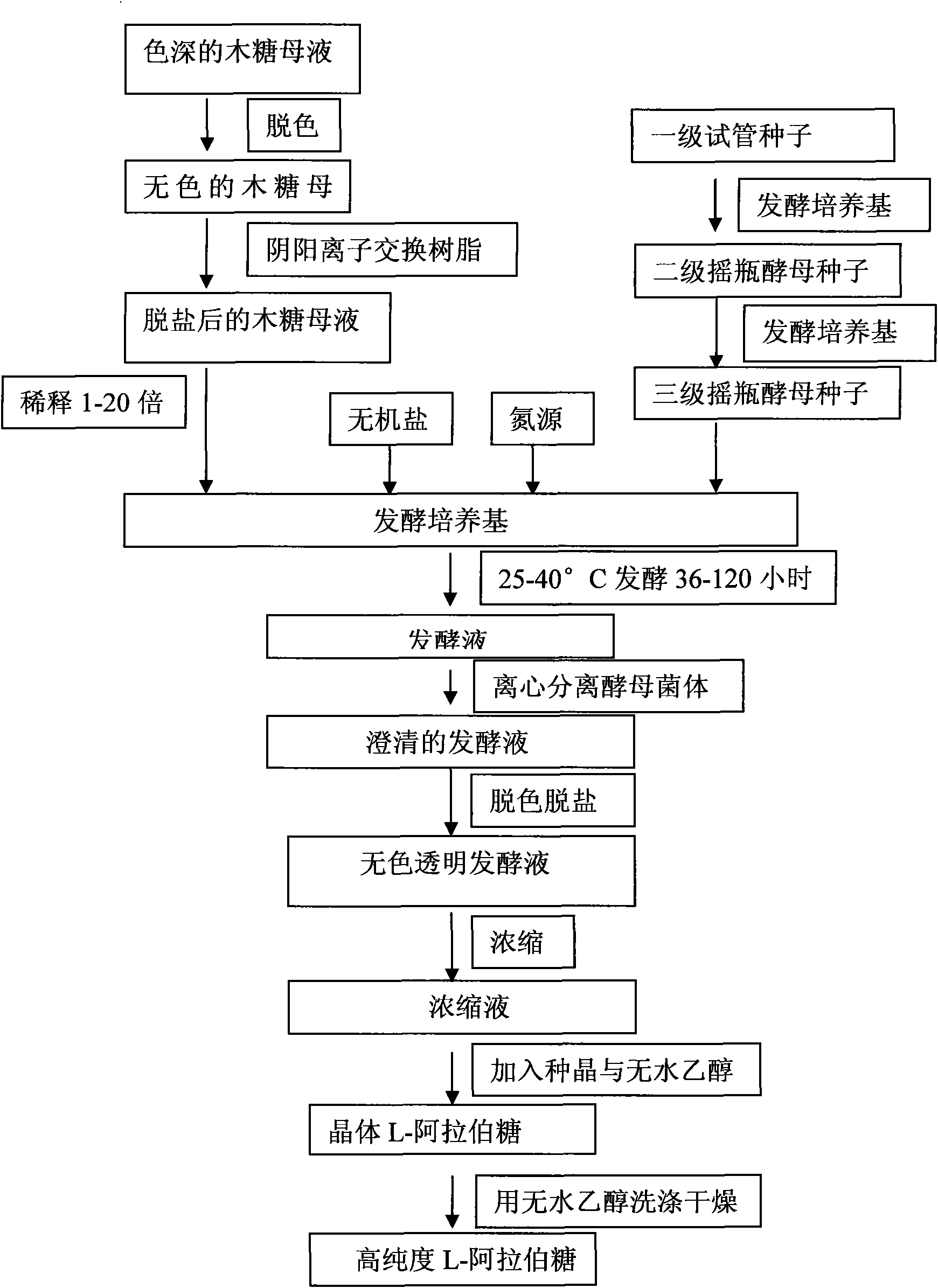

Method used

Image

Examples

Embodiment 1

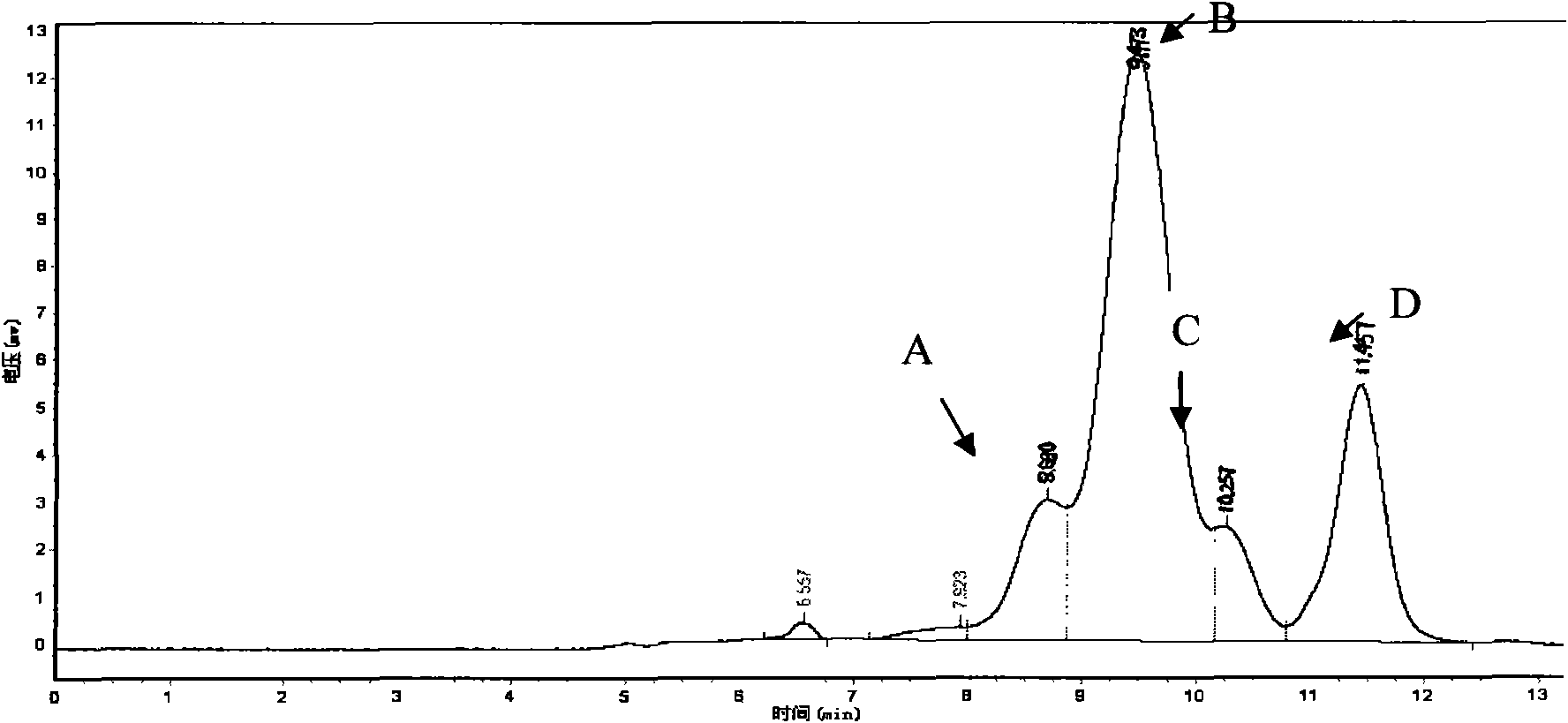

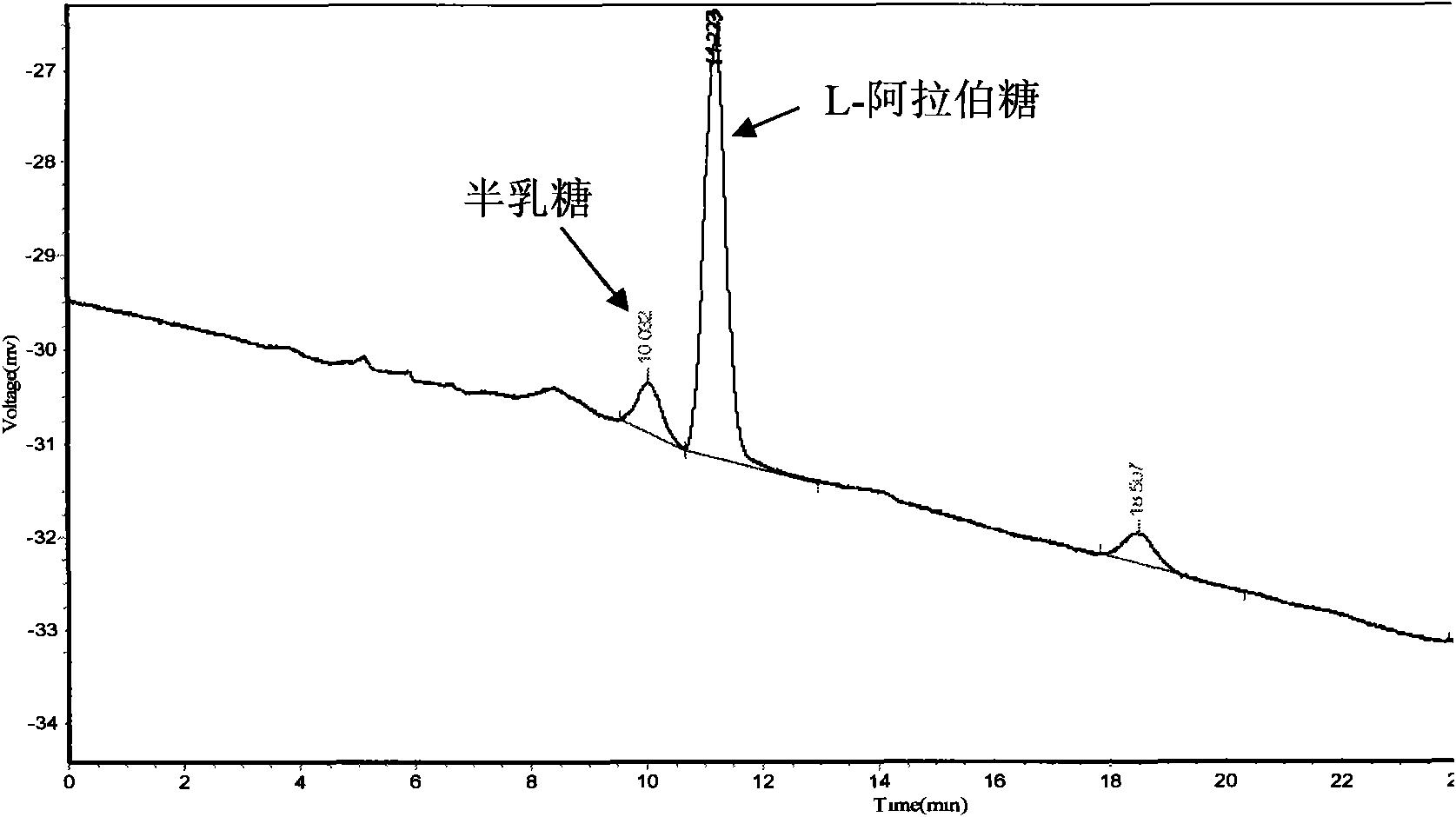

[0051] Take by weighing 1000 grams of xylose mother liquor, this mother liquor comes from the mother liquor that stays after preparing xylose with corncob hydrolyzate crystallization, the selected xylose mother liquor contains 55% D-xylose, 20% L-arabinose, 15 % glucose, 3% galactose and the remaining other miscellaneous sugars, add 10 grams of activated carbon powder, decolorize at 80 ° C for 60 minutes, and stir from time to time, the stirring speed is 100 revolutions per minute, and filter with filter cloth. The filtrate enters the macroporous resin for decolorization, and the decolorized solution enters the 001*7 type cation exchange column-201*7 type anion exchange column-001*7 type cation exchange column to exchange and remove the ions in the mother liquor. Dilute the decolorized and desalted mother liquor five times with tap water, add 1% yeast powder, 0.01% anhydrous magnesium sulfate and 0.1% dipotassium hydrogen phosphate, fully dissolve, and put it into a 10-liter fe...

Embodiment 2

[0053] Take by weighing 1500 grams of xylose mother liquor, this mother liquor comes from the mother liquor that stays after preparing xylose with corncob hydrolyzate crystallization, the selected xylose mother liquor contains 40% D-xylose, 15% L-arabinose, 15% % glucose, 3% galactose and other miscellaneous sugars, add 20 grams of activated carbon powder, decolorize at 80°C for 60 minutes, and stir from time to time, the stirring speed is 100 revolutions per minute, and filter with filter cloth. The decolorizing solution enters the macroporous strongly acidic styrene cation exchange resin D001 exchange column - the macroporous strong basic styrene anion exchange resin D201 column - the macroporous strong acidic styrene cation exchange resin D001 column for exchange to remove ions in the mother liquor. Dilute the decolorized and desalted mother liquor four times with purified water, add 1.5% yeast powder by mass percentage, 0.01% anhydrous magnesium sulfate and 0.1% dipotassium...

Embodiment 3

[0055]Take by weighing 1000 grams of xylose mother liquor, this mother liquor comes from the mother liquor that stays after preparing xylose with corncob hydrolyzate crystallization, the selected xylose mother liquor contains 50% D-xylose, 20% L-arabinose, 15 % glucose, 3% galactose and the rest of other miscellaneous sugars, first add 10 grams of activated carbon powder, decolorize at 60 ° C for 30 minutes, and stir from time to time, the stirring speed is 100 rpm, filter with filter cloth, decolorize The liquid goes through D900 decolorization and adsorption macroporous resin for two-step decolorization, and the decolorization liquid enters the macroporous weakly acidic acrylic cation exchange resin D113 exchange column-macroporous weak base styrene anion exchange resin D301 exchange column to exchange and remove ions in the mother liquor. Dilute the decolorized and desalted mother liquor three times with purified water, add 1% cottonseed powder by mass percentage, 0.2% yeast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com