Method for synthesizing citric acid glyceride by immobilized lipase catalysis in rotatory evaporator

A technology of glyceryl citrate and immobilized lipase, which is applied in the field of synthesis of glyceryl citrate, can solve the problems of cumbersome steps and difficult separation, and achieve the effect of strong specificity, easy removal and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

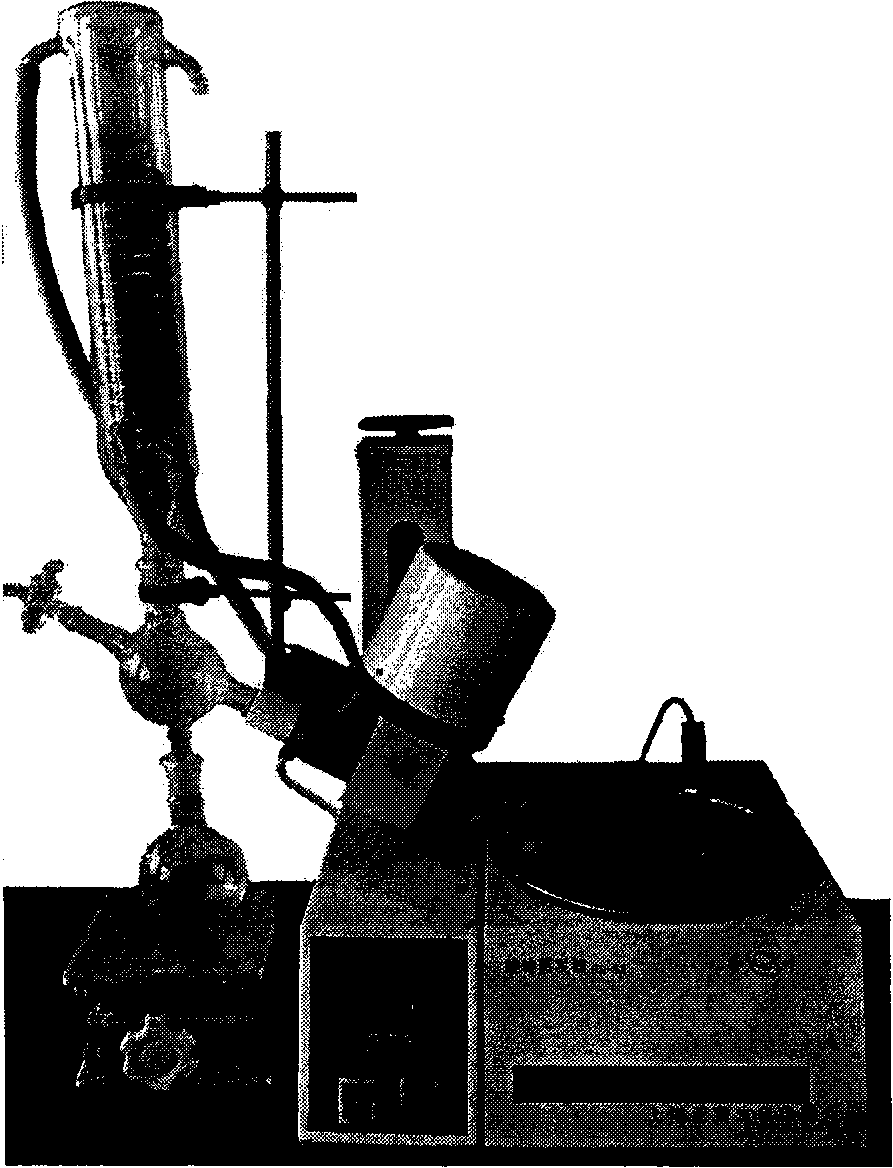

Image

Examples

Embodiment 1

[0020] Add 0.1921g (0.001mol) of citric acid and 0.7171g (0.002mol) of monoglyceride, 10mL of anhydrous isopropanol into a round bottom flask, and heat to 40°C. After the substrate was fully dissolved, 900 mg of immobilized Rhizomucor miehei lipase Lipozyme RM IM was added, and the round-bottomed flask was placed in a rotary evaporator to react at 45°C with a rotation speed of 120 rpm and a vacuum of 0.1 MPa for 40 h. After the reaction was finished, sampling and analysis showed that the conversion rate of citric acid reached more than 70%. The organic solvent was removed by distillation under reduced pressure, the rotation speed was 120 rpm, the vacuum degree was 0.1 MPa, and the temperature was 75° C. to obtain glycerol citrate. After analysis, the acid value of the product is 90-100 mgKOH / g, and the saponification value is 260-265 mgKOH / g.

Embodiment 2

[0022] Add 0.1921g of citric acid and 0.3586g of monoglyceride, 5mL of anhydrous isoamyl alcohol into a round bottom flask, and heat to 40°C. After the substrate was fully dissolved, 550 mg of immobilized Rhizomucor miehei lipase Lipozyme RM IM was added, and the round-bottomed flask was placed in a rotary evaporator, and reacted at 45°C with a rotation speed of 120 rpm and a vacuum of 0.1 MPa for 40 h. After the reaction was finished, sampling and analysis showed that the conversion rate of citric acid reached more than 70%. The organic solvent was removed by distillation under reduced pressure, the rotation speed was 120 rpm, the vacuum degree was 0.1 MPa, and the temperature was 75°C. After vacuum distillation, filter while hot to remove unreacted suspended solids in the oil phase, 95% (w / w) of which is unesterified citric acid. Wash the oil phase with an equal volume of water at a temperature of 50° C., centrifuge to collect the oil phase, and repeat 3 times. After the o...

Embodiment 3

[0024] Add 0.1921g of citric acid and 0.3586g of monoglyceride, 5mL of anhydrous tert-amyl alcohol into a round bottom flask, and heat to 40°C. After the substrate was fully dissolved, 550 mg of immobilized Candida antarctica lipase Novozym 435 was added, and the round-bottomed flask was placed in a rotary evaporator, and reacted at 50°C with a rotation speed of 120 rpm and a vacuum of 0.1 MPa for 30 h. After the reaction was finished, sampling and analysis showed that the conversion rate of citric acid reached more than 70%. The organic solvent was removed by distillation under reduced pressure, the rotation speed was 120 rpm, the vacuum degree was 0.1 MPa, and the temperature was 85°C. After vacuum distillation, filter while hot to remove unreacted suspended solids in the oil phase, 95% (w / w) is unesterified citric acid. Wash the oil phase with an equal volume of water at a temperature of 50° C., centrifuge to collect the oil phase, and repeat 3 times. After the oil phase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com