Device and method for depositing acid-resistant and alkaline-resistant diamond film on surface of compact disc

A diamond film, acid and alkali resistance technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problem of less research on the effect of DLC film on the corrosion resistance of glass, and improve chemical stability. performance, low energy consumption, smooth surface of the disc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

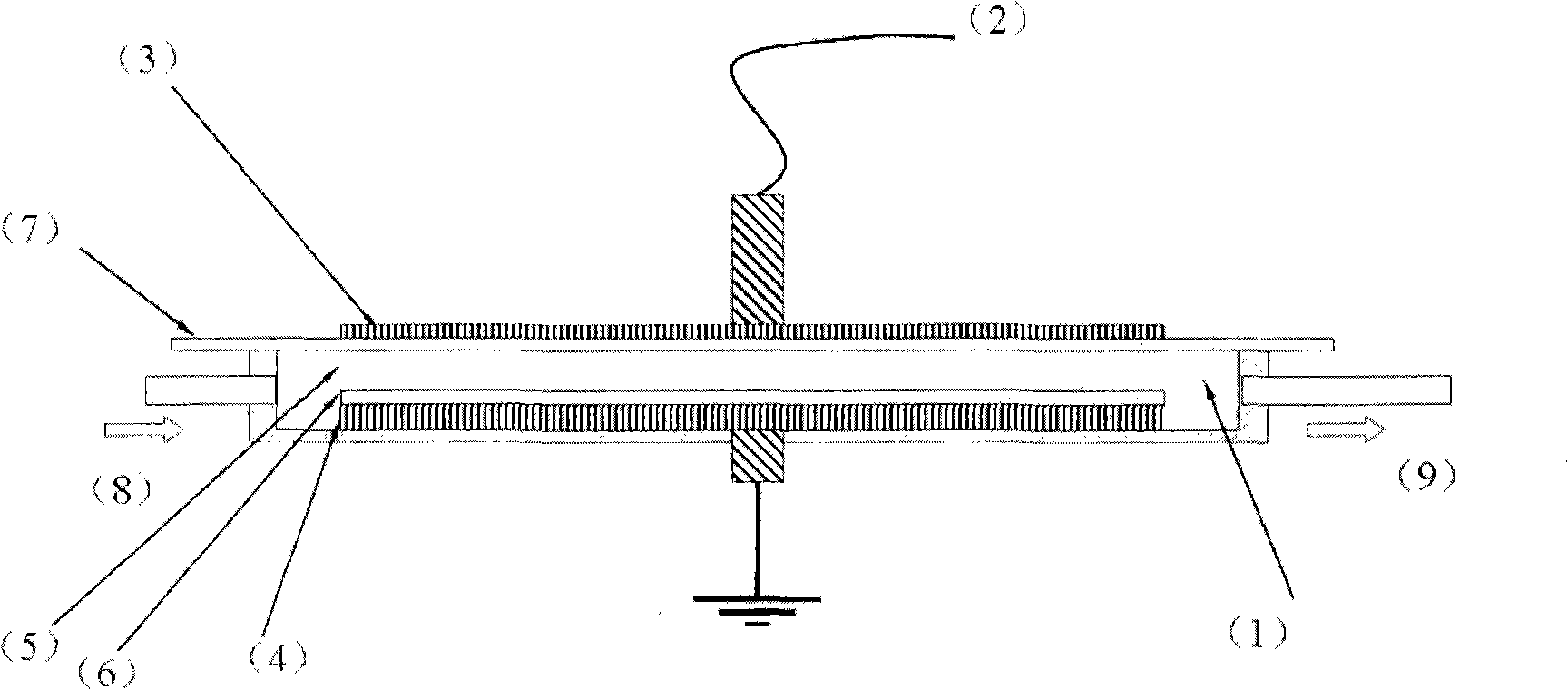

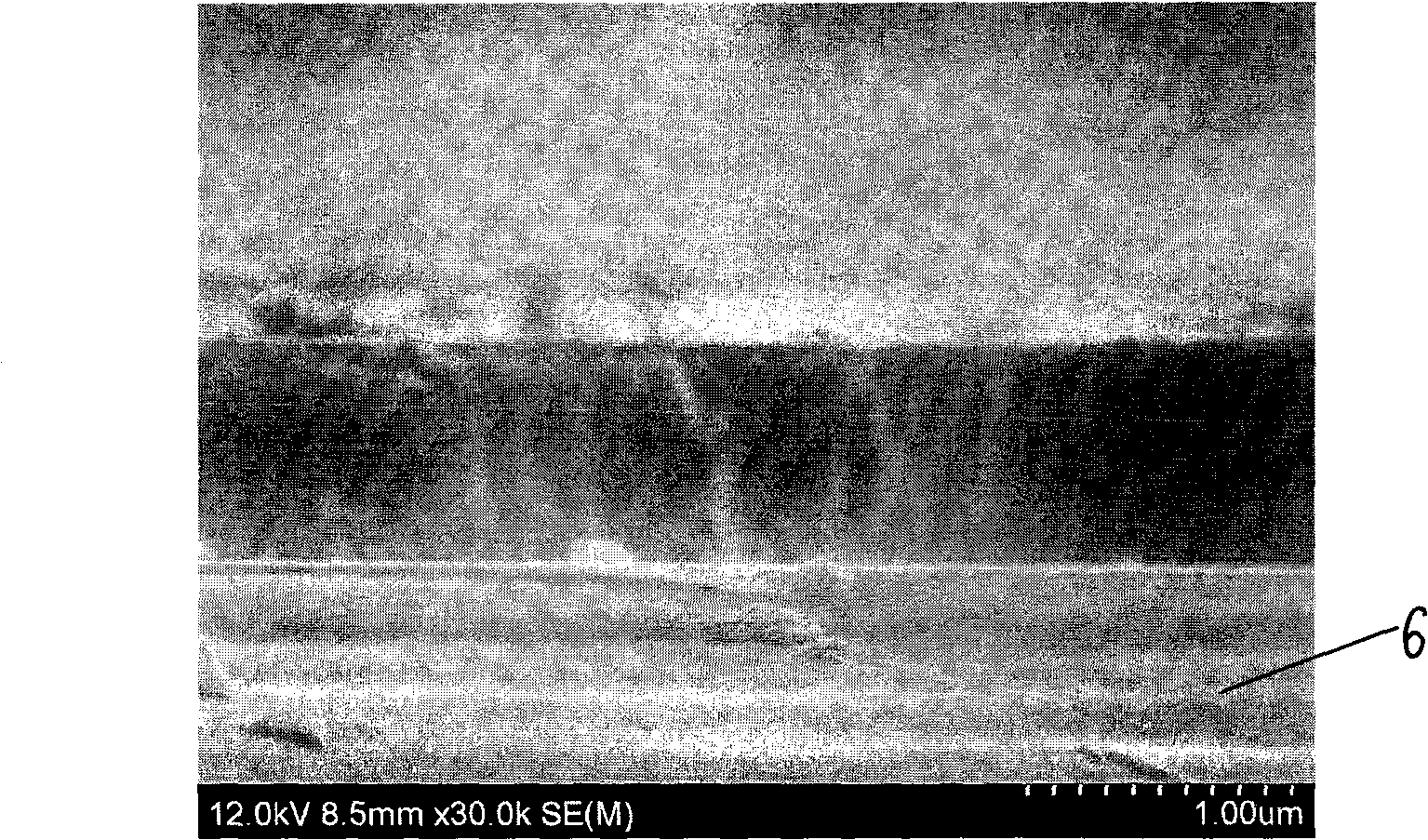

[0020] Such as figure 1 In the device for depositing a diamond-like film on the surface of a dielectric barrier discharge plasma optical disc, the discharge plasma chamber (1) is a vacuum sealed chamber. The AC sine wave high voltage (2) used to generate plasma is connected to the high voltage electrode (3), and the plasma (5) is generated on the gas gap between the high voltage electrode and the ground electrode (4) after high voltage discharge. The size of the gas gap is adjustable between 1-10mm. The clean disc (6) is placed on the ground electrode as a deposition base, and active species generated by the plasma are deposited on the surface of the disc to form a diamond-like film. The glass medium (7) acts as an insulating medium for generating dielectric barrier discharge. Discharge gas such as Ar, CH 4 、C 2 h 4 etc. enter by air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com