Strong correlation electron system-based organic solar cell and preparation method thereof

A solar cell and strong correlation technology, which is applied in the direction of electrical solid-state devices, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as the inability to explain the main physical properties of the system, and achieve the goal of improving electron transmission capabilities, blocking damage, and improving transmission capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

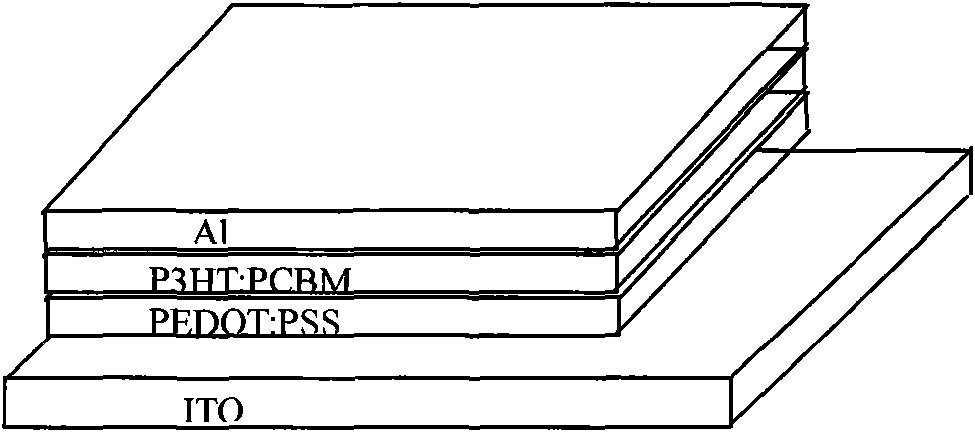

[0028] Embodiment 1, reference device one

[0029] Prepare reference device 1 according to the following steps:

[0030] (1) Cleaning ITO (indium tin oxide): Ultrasonic cleaning in deionized water, acetone, and ethanol for 10 minutes, and then processing in a plasma cleaning instrument for 1 minute;

[0031] (2) Spin-coat the hole buffer layer PEDOT:PSS on the anode ITO, wherein PEDOT:PSS / H in the PEDOT:PSS aqueous solution 2 O=1 / 4 (volume ratio, the same below), filter head pore size 0.2 microns, rotating speed 3000 rpm, spin coating time 30 seconds, anneal at 200°C after spin coating, after 5 minutes in air, in vacuum (<10Pa ) for 15 minutes, cool down;

[0032] (3) Spin-coat the photoactive layer P3HT:PCBM mixed solution on the hole buffer layer PEDOT:PSS, wherein the concentration of the mixed solution is P3HT:PCBM / ortho-dichlorobenzene=(15mg:12mg) / ml, that is, every milliliter of ortho-dichlorobenzene Contain 15mgP3HT and 12mg PCBM in the chlorobenzene solvent, the ape...

Embodiment 2

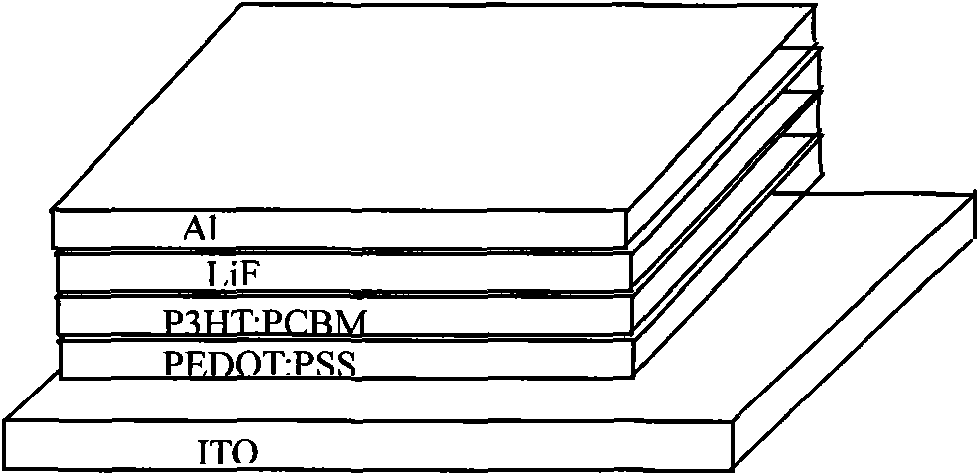

[0035] Embodiment 2, reference device two

[0036] Reference device 2 was prepared according to the following steps:

[0037] (1) Cleaning ITO (indium tin oxide): Ultrasonic cleaning in deionized water, acetone, and ethanol for 10 minutes, and then processing in a plasma cleaning instrument for 1 minute;

[0038] (2) Spin-coat the hole buffer layer PEDOT:PSS on the anode ITO, wherein PEDOT:PSS / H in the PEDOT:PSS aqueous solution 2 O=1 / 4, filter head pore size 0.2 micron, rotating speed 3000 rpm, spin coating time 30 seconds, anneal at 200°C after spin coating, after 5 minutes in air, 15 minutes in vacuum (<10Pa), cool down;

[0039] (3) Spin-coat the photoactive layer P3HT:PCBM mixed solution on the hole buffer layer PEDOT:PSS, wherein the mixed solution concentration is P3HT:PCBM / o-dichlorobenzene=(15mg:12mg) / ml, and the filter head aperture is 0.2 microns , rotating speed 600~800 rev / min, spin coating time 15 seconds, anneal at 150 ℃ after the solvent volatilizes after spi...

Embodiment 3

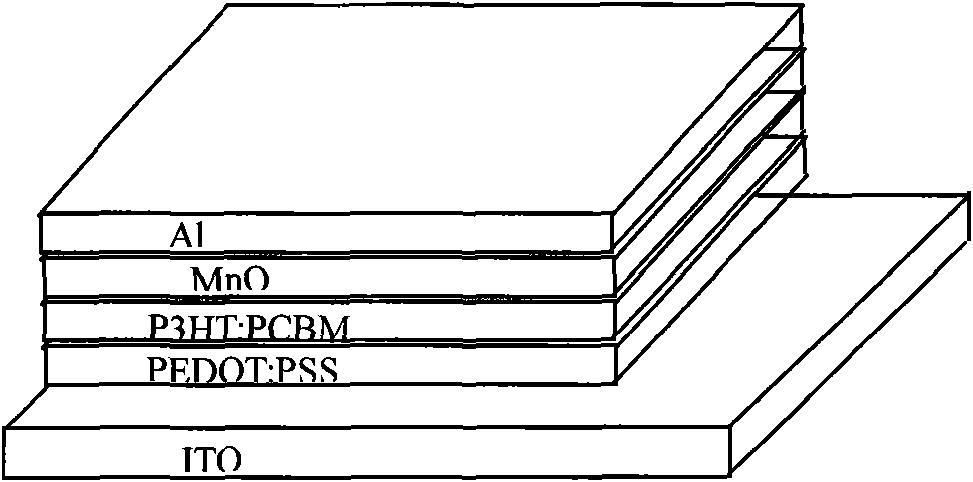

[0043] Embodiment 3, implementation device

[0044] 1. Materials:

[0045] The OSC device based on classical materials adds an electron buffer layer formed by a strongly correlated electron system compound. The structure of the OSC is: ITO / PEDOT:PSS / P3HT:PCBM / MnO / Al. First, the hole buffer layer PEDOT:PSS is spin-coated on the ITO, and then the photoactive layer P3HT:PCBM is spin-coated on the hole buffer layer, and then the strongly correlated electron system compound-manganese oxide (MnO) is vacuum evaporated on the P3HT:PCMB. ), and finally vacuum-evaporated cathode Al on MnO. Device structure see Figure 1c .

[0046] 2. Device preparation method:

[0047] (1) Cleaning ITO (indium tin oxide): Ultrasonic cleaning in deionized water, acetone, and ethanol for 10 minutes, and then processing in a plasma cleaning instrument for 1 minute;

[0048] (2) Spin-coat the hole buffer layer PEDOT:PSS on the anode ITO, where PEDOT:PSS aqueous solution PEDOT:PSS / H 2 O=1 / 4, filter he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com