Preparation method of nanometer cobweb/ nanometer fiber composite protective material

A technology of nanofibers and protective materials, applied in fiber processing, filament/thread forming, chemical instruments and methods, etc., can solve the problems of large pore size of protective materials and poor virus filtering effect, and achieve low price, high protection rate, Good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] At room temperature of 25°C, 0.5 g of nylon 6 was stirred and dissolved in 9.5 g of formic acid solution at a rotating speed of 50 rpm / min, and stirred until all the solids were dissolved, and the solution was a colorless and transparent liquid to obtain a nylon 6 solution with a mass fraction of 5%.

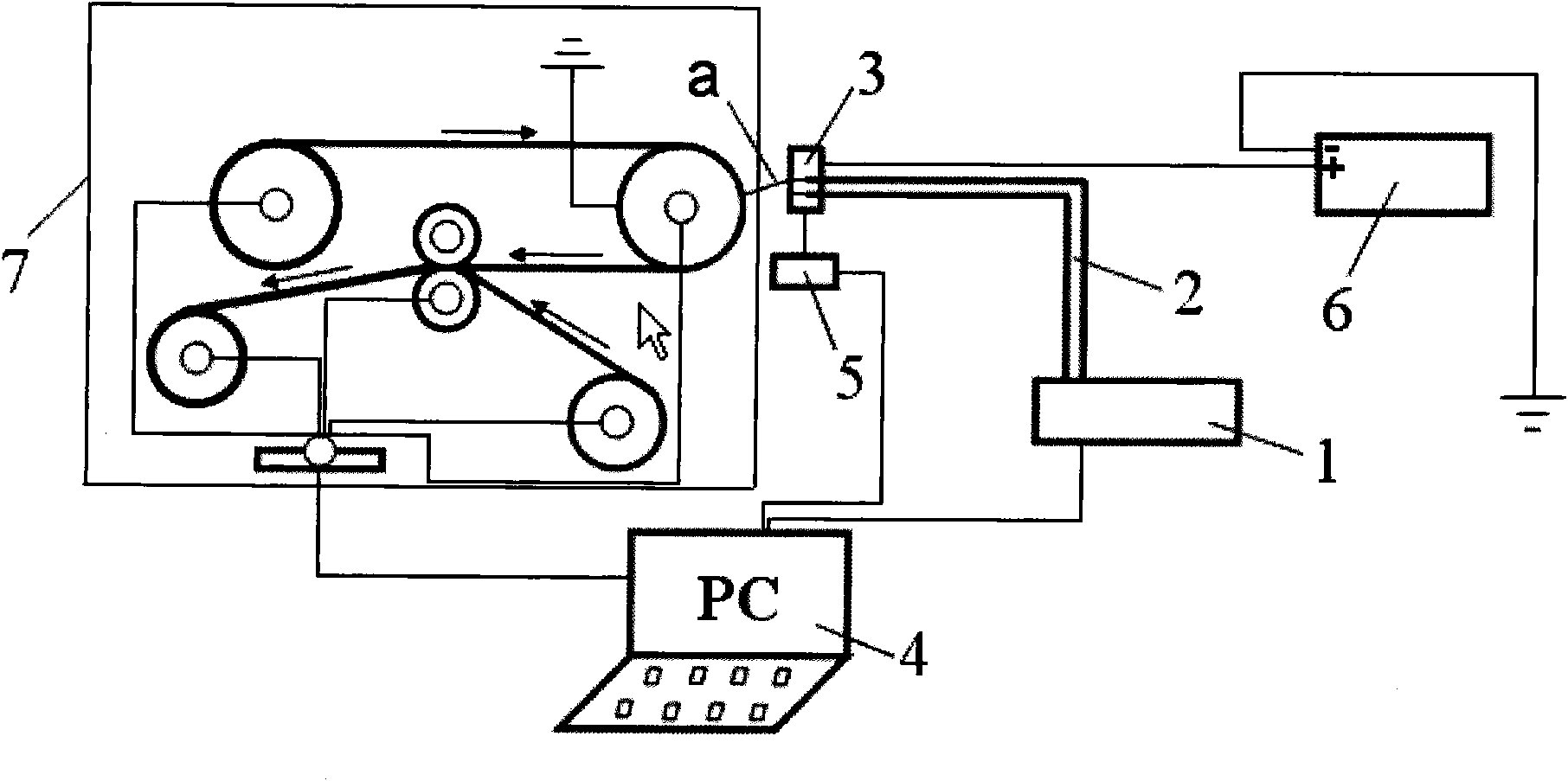

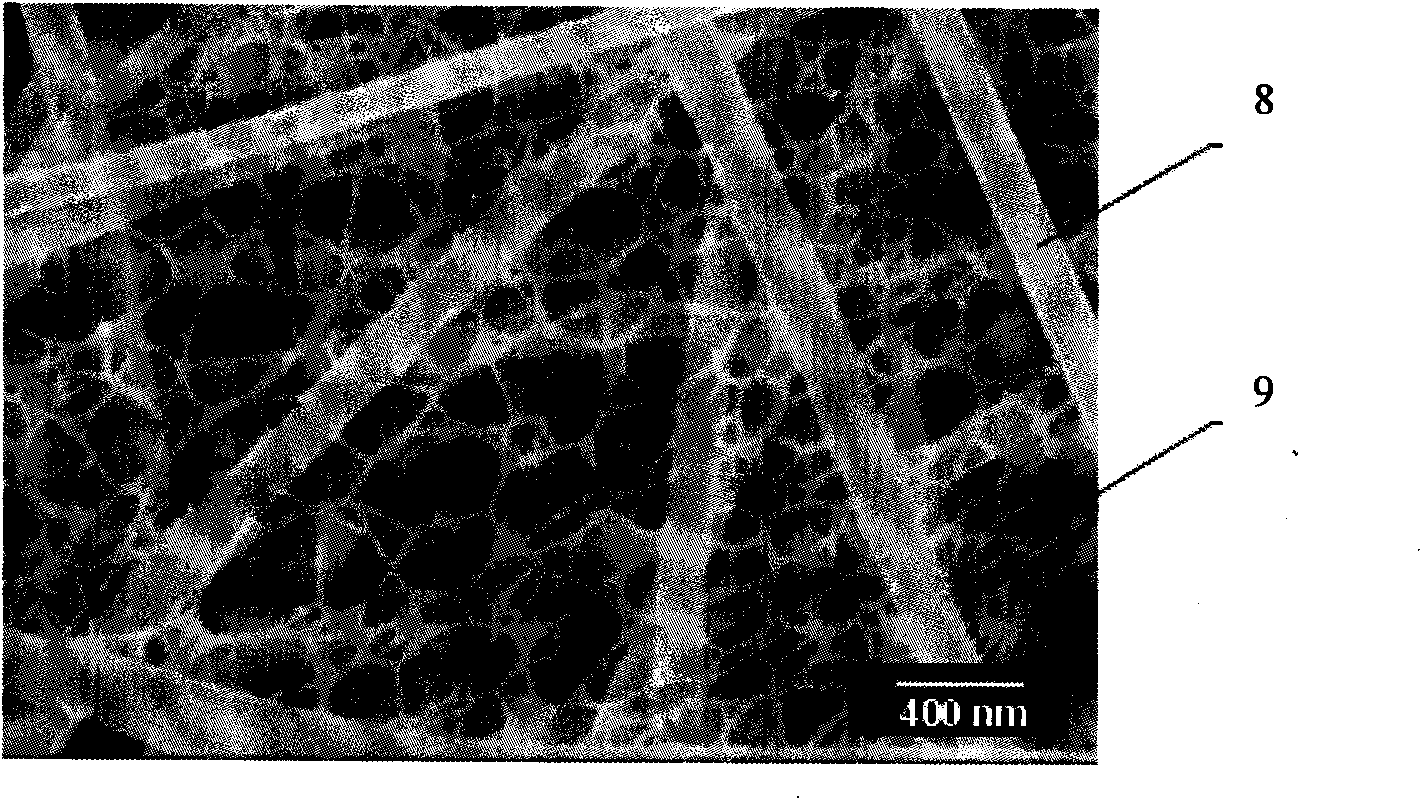

[0020] Under the conditions of room temperature of 25°C and humidity of 30%, a nylon 6 solution with a mass fraction of 5% was input to the spinneret of the self-cleaning multi-nozzle matrix array spinneret 3 through the liquid supply device 1 at a flow rate of 0.1 mL / h. On, the spinneret is connected with the high-voltage electrostatic generator 6 of 10 kilovolts to carry out electrospinning simultaneously, and the spun silk is covered with a layer of top material aluminum foil after receiving with a layer of base material aluminum foil placed on the receiving device 7 drum, The vertical distance a between the spinneret and the substrate is 5 cm, and the nano-cobweb / nanof...

Embodiment 2

[0022] At room temperature of 25°C, 1.5g of polyacrylic acid was stirred and dissolved in 18.5g of ethanol (95wt%) solution at a rotating speed of 1200rpm / min, and stirred until all the solids were dissolved, and the solution was colorless and transparent to obtain a polyacrylic acid solution with a mass fraction of 7.5% .

[0023] Under the conditions of room temperature of 25°C and humidity of 30%, a polyacrylic acid solution with a mass fraction of 7.5% was input to the spinnerets of the self-cleaning multi-nozzle matrix array spinneret 3 through the liquid supply device 1 at a flow rate of 10mL / h At the same time, the spinneret is connected to the high-voltage electrostatic generator 6 of 80 kV for electrospinning, and the spun silk is received by a layer of base non-woven fabric placed on the drum of the receiving device 7 and then covered with a layer of non-woven fabric. , the vertical distance a between the spinneret and the substrate is 30 cm, and hot pressing at 40° ...

Embodiment 3

[0025] At room temperature of 25°C, 5g of polyvinyl alcohol was stirred and dissolved in a mixed solution of 15g of ethanol (95wt%) and formic acid (weight ratio 3:1) at a rotating speed of 2000rpm / min, stirred until the solid was completely dissolved, and the solution was a yellow transparent liquid, A polyvinyl alcohol solution with a mass fraction of 25% was obtained.

[0026] Under the conditions of room temperature of 25°C and humidity of 30%, the polyvinyl alcohol solution with a mass fraction of 25% was input to the spinneret of the self-cleaning multi-nozzle matrix array spinneret 3 through the liquid supply device 1 at a flow rate of 6mL / h At the same time, the spinneret is connected to the high-voltage electrostatic generator 6 of 60 kV to carry out electrospinning, and the spun silk is received with a layer of copper mesh of the base material placed on the drum of the receiving device 7 and then covered with a layer of copper mesh, The vertical distance a between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com