Last stage vane of steam turbine and preparation method thereof

The technology of the last stage blade and steam turbine is applied in the field of the last stage blade of a steam turbine and its preparation, which can solve the problem that the water erosion resistance of the last stage blade is difficult to fully meet the requirements of water erosion resistance, and achieve good hydrophobic performance, reduce cost, and reduce coating stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

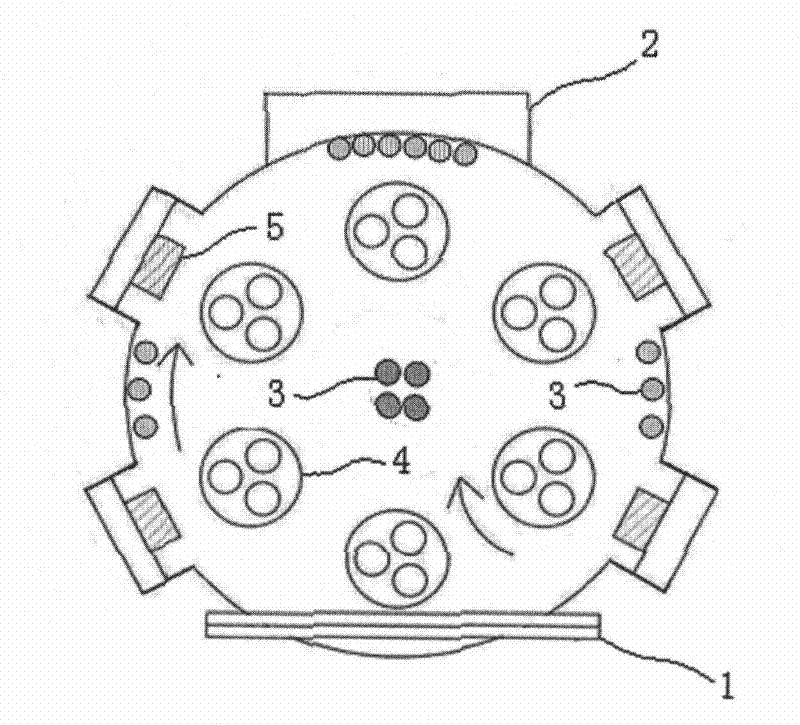

Method used

Image

Examples

Embodiment 1

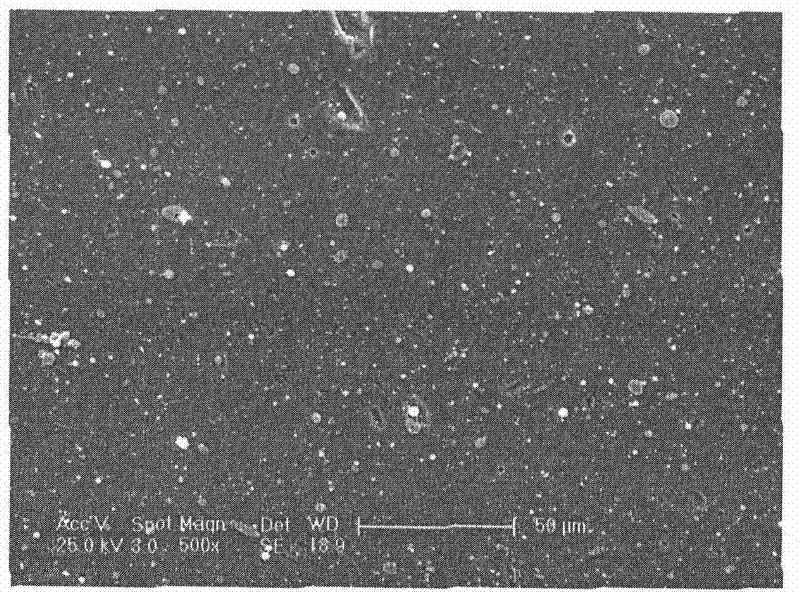

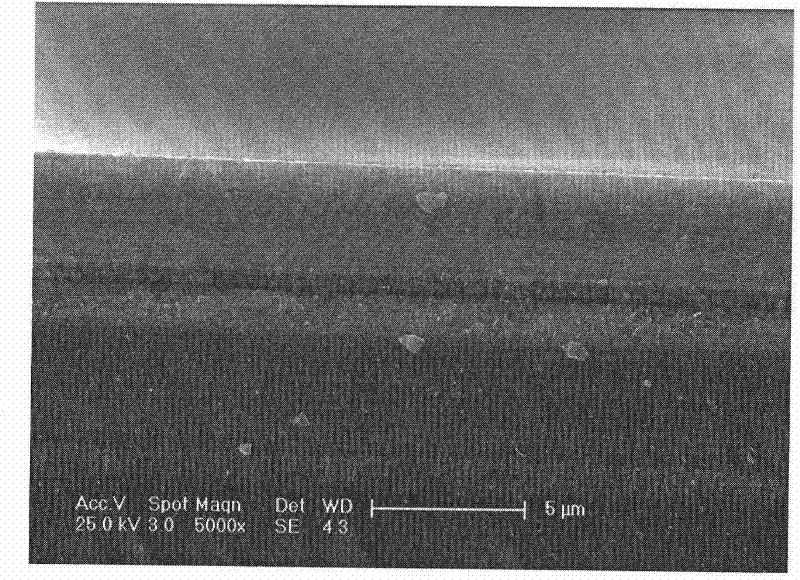

[0024] Example 1: Glow cleaning is performed on the final blade after nitriding treatment at 400°C and argon atmosphere. During the glow discharge, the bias voltage on the workpiece is -1200V, and the glow time is 30 minutes; After cleaning, deposit a 150 nanometer-thick transition metal Cr layer by arc discharge at 0.05 Pa; then deposit a 6-micron CrSiN water corrosion resistant layer by arc discharge at 300°C, -150V bias, and 2.3 Pa pressure. The size of the CrN nanocrystals is 5 nanometers, and the silicon content in the coating is 8at.%; when the water corrosion resistant layer is deposited, 4 microns of Cr is deposited by arc discharge method at 250℃, -200V bias voltage and 3.3Pa pressure. 2 O 3 / SiO 2 Waterproof layer, of which Cr 2 O 3 The nanocrystal size is 4 nanometers, and the silicon content in the coating is 10at.%; after the preparation is finished, it is naturally cooled to obtain the final blade of the chromium-based ceramic composite coating.

Embodiment 2

[0025] Example 2: Glow cleaning is performed on the final blade after nitriding treatment at 450°C and argon atmosphere, the bias voltage on the workpiece during the glow discharge process is -1200V, and the glow time is 30 minutes; After cleaning, deposit a 200nm thick transition metal Cr layer by arc discharge method under 0.06Pa conditions; then deposit 8 micron CrSiN water corrosion resistant layer by arc discharge method under 350℃, -180V bias voltage and 3Pa pressure conditions, in which CrN The nanocrystal size is 7 nanometers, and the silicon content in the coating is 10at.%; when the water corrosion resistant layer is deposited, 5 microns of Cr is deposited by arc discharge method under 300℃, -150V bias voltage and 3.3Pa pressure conditions 2 O 3 / SiO 2 Waterproof layer, of which Cr 2 O 3 The nanocrystal size is 6 nanometers, and the silicon content in the coating is 15at.%; after the preparation is finished, it is naturally cooled to obtain the final blade of the chromi...

Embodiment 3

[0026] Example 3: Glow cleaning is performed on the final blade after nitriding treatment at 430°C and argon atmosphere, the bias voltage on the workpiece during the glow discharge process is -1200V, and the glow time is 30 minutes; After cleaning, a 180-nanometer thick transition metal Cr layer was deposited by arc discharge at 0.05 Pa; then a 10 micron CrSiN water corrosion resistant layer was deposited by arc discharge at 320°C, -190V bias and 4 Pa pressure, in which CrN The nanocrystalline size is 8 nanometers, and the silicon content in the coating is 15at.%; when the water corrosion resistant layer is deposited, 3 micron Cr is deposited by arc discharge method under 300℃, -160V bias voltage and 3.3Pa pressure conditions 2 O 3 / SiO 2 Waterproof layer, of which Cr 2 O 3 The nanocrystal size is 10 nanometers, and the silicon content in the coating is 20 at.%; after the preparation is finished, it is naturally cooled to obtain the final blade of the chromium-based ceramic com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com