Antibacterial cosmetic brush and production method for bristle

A manufacturing method and antibacterial technology, which is applied in the field of manufacturing cosmetic brushes and their bristles, can solve the problems of long drying time, dissolution and detachment of antibacterial agents, and lower concentration of antibacterial agents, and achieve faster drying speed, excellent heat resistance, Excellent safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

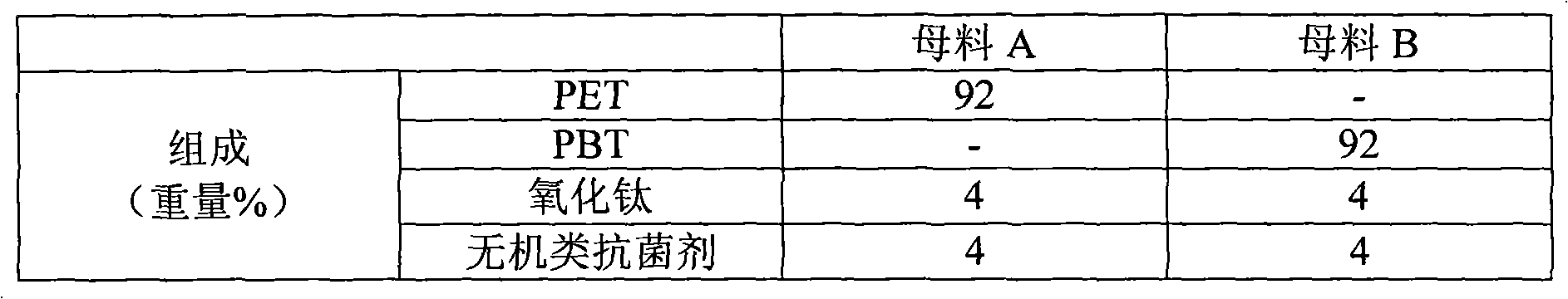

[0057] First, an inorganic antibacterial agent made of silver-based phosphoric acid-boric acid glass with an average particle diameter of 0.5 μm, titanium oxide, and polybutylene terephthalate resin (PBT) or polybutylene terephthalate resin containing no inorganic antibacterial agent are used. Ethylene terephthalate resin (PET) was used to make two kinds of master batches (master batch A and master batch B). The composition is shown in Table 1 below.

[0058] [Table 1]

[0059]

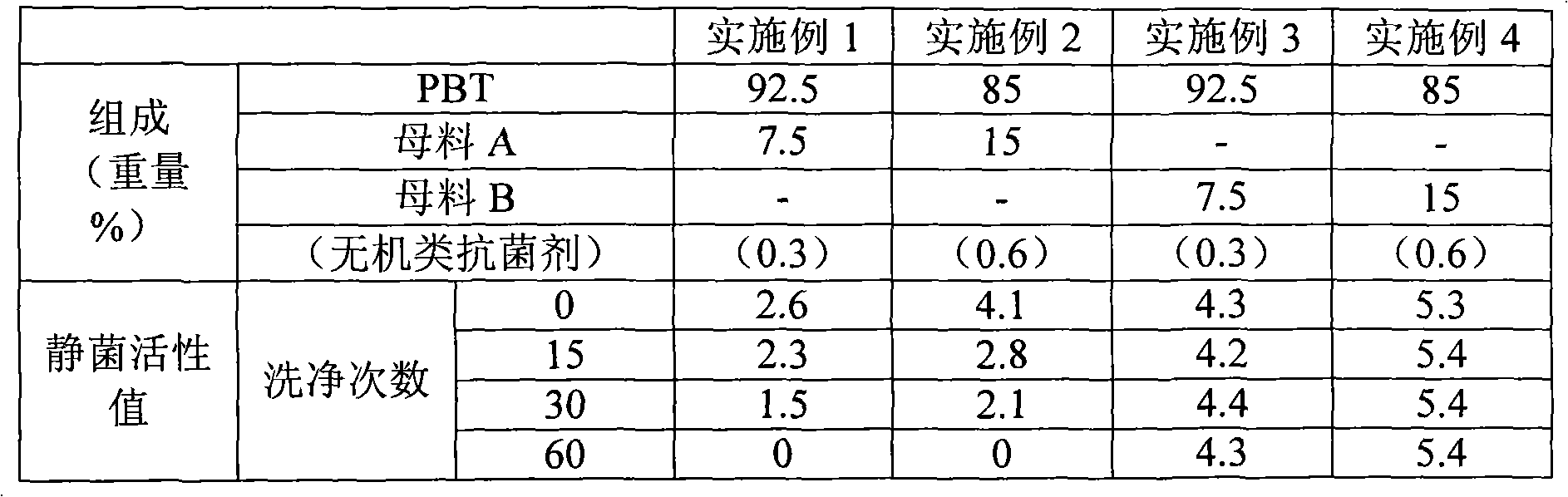

[0060] Next, use the polybutylene terephthalate resin (PBT) as the raw material resin of the fiber and the above-mentioned master batch A or B, melt and mix them in a predetermined ratio, and then use the melt spinning method to spin to form the fiber diameter The synthetic fiber of 0.05 mm was used as the bristles to obtain the cosmetic brushes of Examples 1 to 4. In addition, the obtained cosmetic brushes of Examples 1 to 4 were evaluated for their antibacterial properties in accordance with the above...

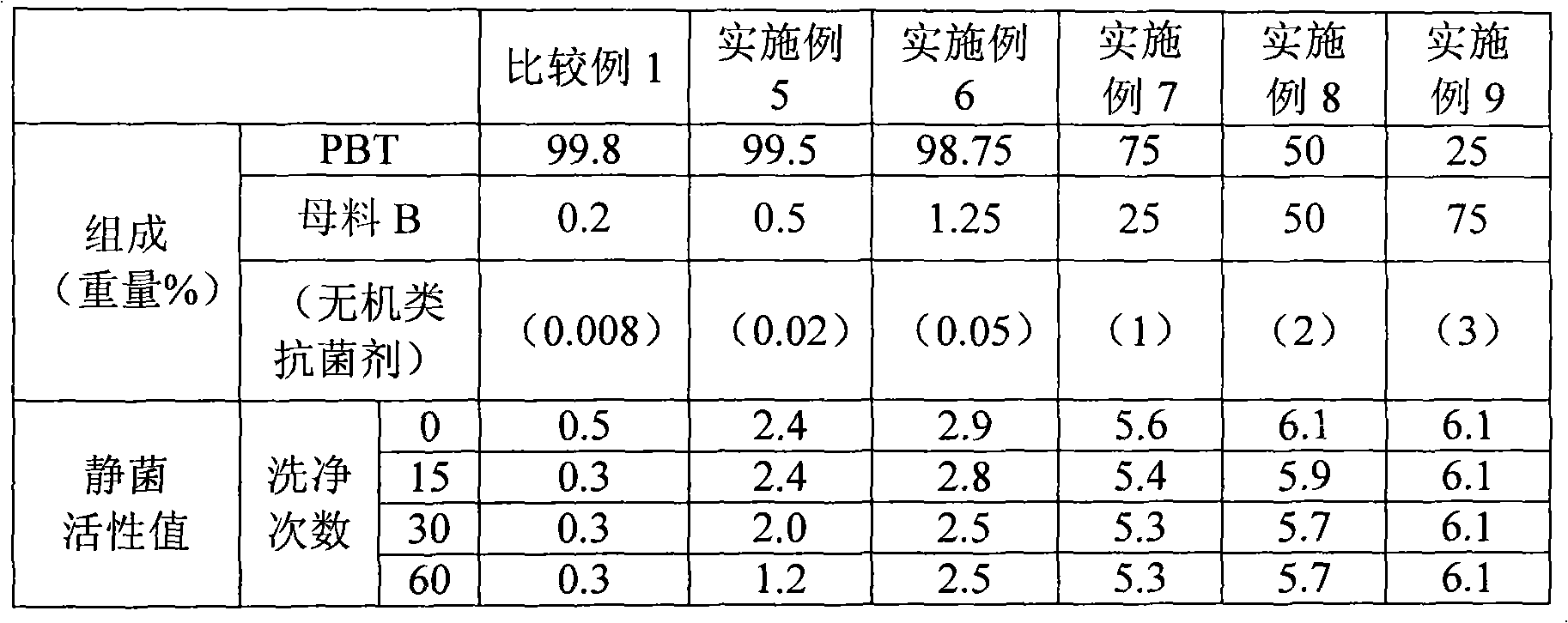

Embodiment 5~9 and comparative example 1

[0067] Using polybutylene terephthalate resin (PBT) as the raw material resin of the fiber and the above-mentioned master batch B, they are melted and mixed in a prescribed ratio, and then spun with a melt spinning method to form a fiber diameter of 0.08 mm Synthetic fiber, using the synthetic fiber as the bristles, the cosmetic brushes of Examples 5 to 9 and Comparative Example 1 were obtained. In addition, the obtained cosmetic brushes of Examples 5 to 9 and Comparative Example 1 were evaluated for their antibacterial properties in accordance with the above-mentioned method. The results are shown in Table 3 below. The values in parentheses in the table indicate the content of inorganic antibacterial agents contained in 100 parts by weight of synthetic fibers.

[0068] [table 3]

[0069]

[0070] As shown in Table 3, it can be seen that in the cosmetic brushes of Examples 5-9 containing 0.02 parts by weight (%) or more of an inorganic antibacterial agent with respect to 100 p...

Embodiment 10~13 and comparative example 2

[0074] First, use inorganic antibacterial agents of various average particle diameters, titanium oxide, and polybutylene terephthalate without inorganic antibacterial agents composed of an equal mixture of silver-zinc-based zeolite and silver-based phosphoric acid glass. Ester resin (PBT) to make masterbatch C. Here, the composition of the master batch C is the same as the master batch B shown in Table 1.

[0075] Next, using the polybutylene terephthalate resin (PBT) as the raw material resin of the fiber and the above masterbatch C, they are melted and mixed in a predetermined ratio, and then spun by the melt spinning method to form a fiber diameter of 0.04 mm synthetic fiber, using the synthetic fiber as the bristles, the cosmetic brushes of Examples 10 to 13 and Comparative Example 2 were obtained. In addition, the obtained cosmetic brushes of Examples 10 to 13 and Comparative Example 2 were evaluated for their antibacterial properties in accordance with the above-mentioned me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com