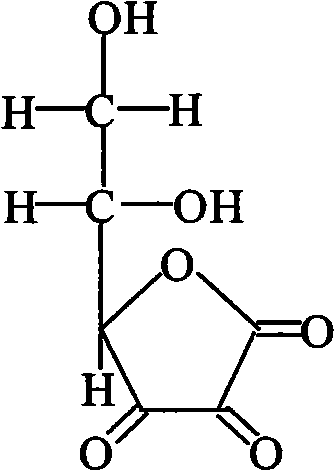

Preparation method for high-purity solid dehydroascorbic acid

A technology for dehydroascorbic acid and ascorbic acid, which is applied in the directions of material separation, instruments, analytical materials, etc., to achieve the effects of easy control, high purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

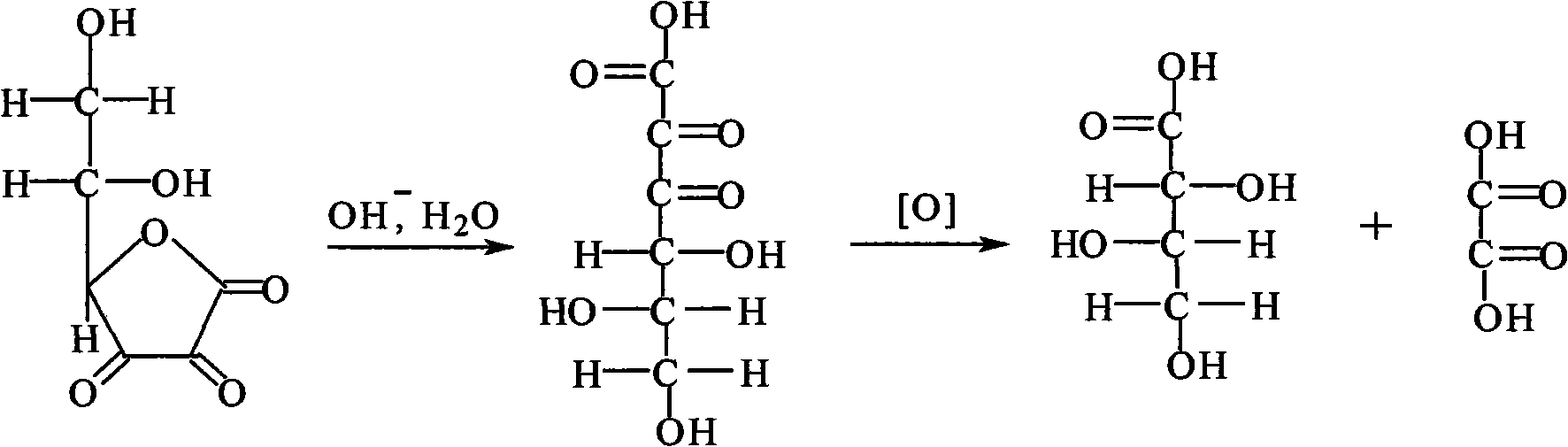

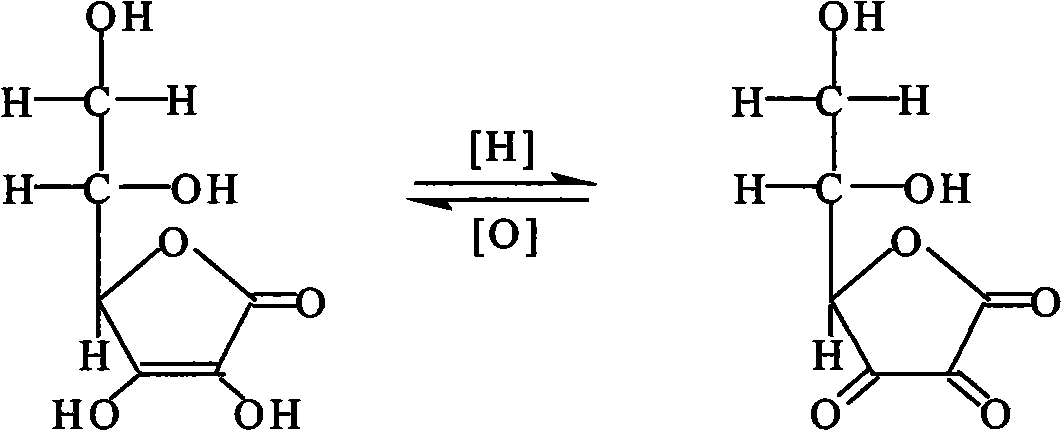

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-purity solid dehydroascorbic acid preparation method that does not need to use toxic substances in the preparation process, is safe, does not cause environmental pollution, and has a simple process, which is:

[0031] 1. Prepare the chromatography column

[0032] Take quantitative commercial silica gel, bake it at 110°C for 2 to 4 hours, then cool it to room temperature in a desiccator, wet-pack the column with acetonitrile, and set it aside;

[0033] 2. Oxidation of L-ascorbic acid (Vc)

[0034] In terms of weight ratio, weigh 237g of absolute ethanol, 10g of activated carbon, and 8g of L-ascorbic acid (Vc) according to the ratio of 29.625:1.25:1, add them to a three-necked bottle, stir at 20°C and feed in air, during which time sampling is used High-performance liquid chromatography is used for analysis to monitor the progress of the reaction. Ethanol volatilizes and is replenished in time until the end of the reaction;

[0035] 3. Remove activated carbon and...

Embodiment 2

[0040] A high-purity solid dehydroascorbic acid preparation method that does not need to use toxic substances in the preparation process, is safe, does not cause environmental pollution, and has a simple process, which is:

[0041] 1. Prepare the chromatography column

[0042] Take quantitative commercial silica gel, soak it in concentrated hydrochloric acid for 4 hours, filter it with suction, wash it with distilled water until it does not contain chloride ions, dry it and activate it in an oven at 120°C for 2 hours, then wet-pack it with acetonitrile for use;

[0043] 2. Oxidation of L-ascorbic acid (Vc)

[0044] In terms of weight ratio, weigh 316g of anhydrous methanol, 12g of activated carbon, and 8g of L-ascorbic acid (Vc) according to the ratio of 39.50:1.5:1, add them into a three-necked bottle, stir at 30°C and pass in air. High-performance liquid chromatography is used for analysis to monitor the progress of the reaction. Methanol volatilizes and replenishes in time...

Embodiment 3

[0050] A high-purity solid dehydroascorbic acid preparation method that does not need to use toxic substances in the preparation process, is safe, does not cause environmental pollution, and has a simple process, which is:

[0051] 1. Prepare the chromatography column

[0052] Take quantitative commercial silica gel, bake it at 100°C for 4 hours, then cool it to room temperature in a desiccator, and wet-pack the column with acetonitrile for use;

[0053] 2. Oxidation of L-ascorbic acid (Vc)

[0054] In terms of weight ratio, weigh 395g of absolute ethanol, 18g of activated carbon treated with 10% hydrochloric acid, and 10g of L-ascorbic acid (Vc) according to the ratio of 39.5:1.8:1, add them into a three-necked flask, stir at 40°C and pass in During the period, the air was continuously sampled and analyzed by high-performance liquid chromatography to monitor the progress of the reaction. Ethanol volatilized and replenished in time until the end of the reaction;

[0055] 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com