Method for growing upright three-dimensional netlike noble metal nano-plate on boron-doped diamond substrate

A technology of boron-doped diamond and three-dimensional mesh, which is applied in the field of preparation of working electrodes, can solve the problems of low catalytic activity of boron-doped diamond, and achieve the effects of overcoming low catalytic activity, good support function, and broad market development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

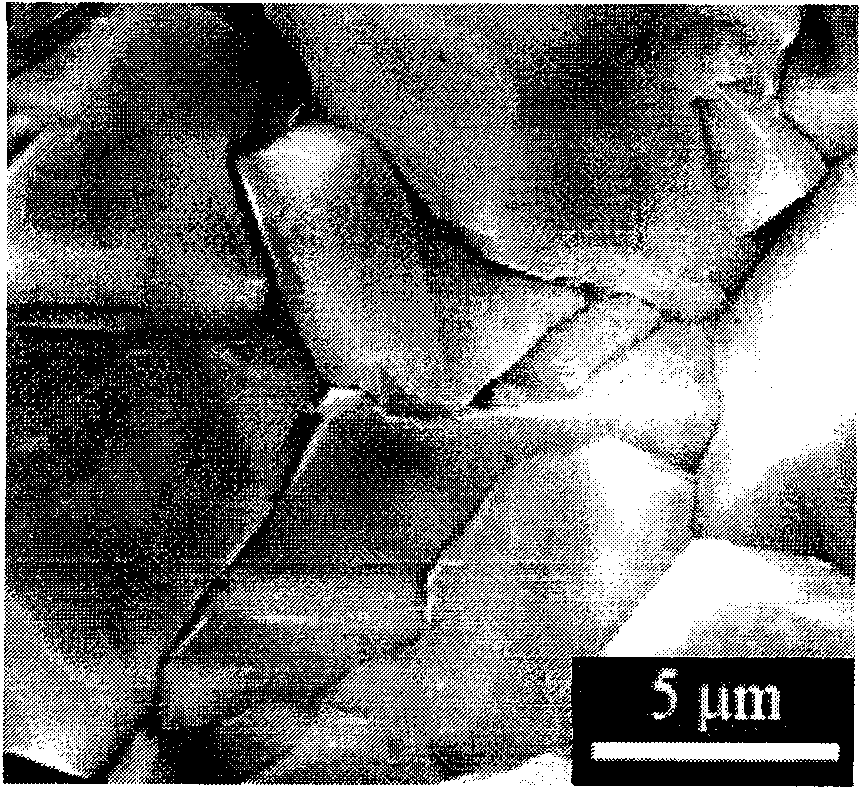

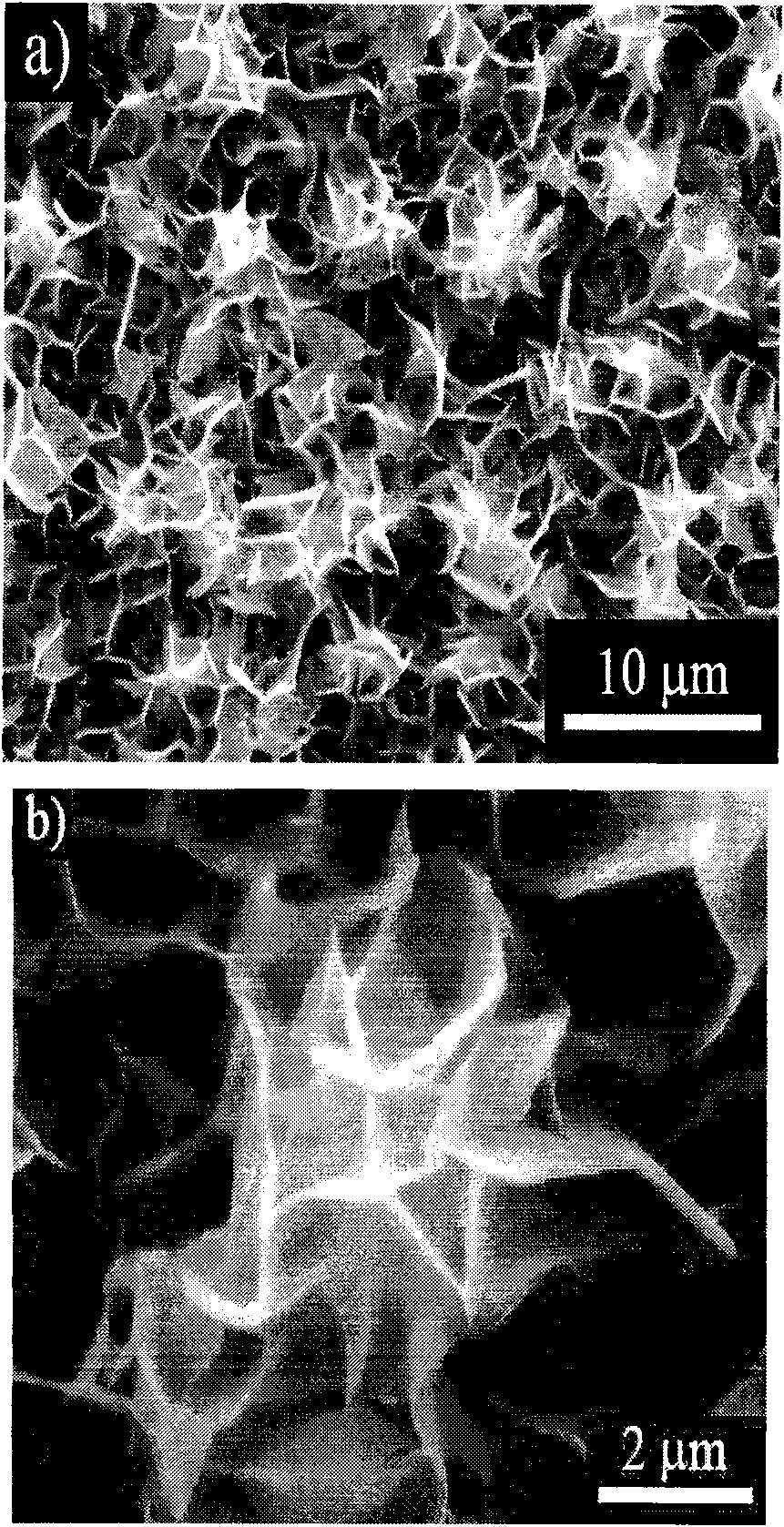

[0024] Set the surface area to 1 cm 2 The boron-doped diamond was heat-treated in aqua regia solution at 90°C for 5 minutes, then ultrasonically treated in ethanol solution for 3 minutes, and then cleaned with deionized water. Then place the treated boron-doped diamond electrode in 0.5mol / L H 2 SO 4 The medium was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode (SCE) was used as the reference electrode. Anodized for 45 minutes at a potential of 3.2V. Then rinse with deionized water twice.

[0025] Electroplating solution is 0.5mol / L ZnCl 2 The supporting electrolyte is 6mol / L KCl. The electrodeposition experiment adopts a three-electrode system, with the surface-treated boron-doped diamond as the working electrode, the platinum sheet as the auxiliary electrode, and the saturated calomel electrode as the reference electrode. A constant current density of 0.15Acm was used -2 Conditions of deposition ...

Embodiment 2

[0027] Set the surface area to 1 cm 2 The boron-doped diamond was heat-treated in aqua regia solution at 70°C for 10 minutes, then ultrasonically treated in ethanol solution for 3 minutes, and then cleaned with deionized water. Then place the processed boron-doped diamond electrode in 1mol / L H 2 SO 4 The medium was used as the working electrode, the platinum sheet was used as the counter electrode, and the saturated calomel electrode (SCE) was used as the reference electrode. Anodized at 3.0V potential for 40 minutes. Then rinse with deionized water twice.

[0028] The electroplating solution is 0.25mol / L ZnCl 2 The supporting electrolyte is 3mol / L KCl. The electrodeposition experiment adopts a three-electrode system, with the surface-treated boron-doped diamond as the working electrode, the platinum sheet as the auxiliary electrode, and the saturated calomel electrode as the reference electrode. A constant current density of 0.1Acm was used -2 Conditions of deposition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com