Nickelous compound anode material used in nickel-hydrogen battery and preparation technique

A composite cathode material, nickel-metal hydride battery technology, applied in battery electrodes, alkaline battery electrodes, circuits, etc., can solve problems such as poor battery performance at high temperature and high current, difficulty in meeting requirements for nickel-metal hydride batteries, and inability to meet energy storage needs. , to achieve the effect of good charge and discharge performance, long service life and easy parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

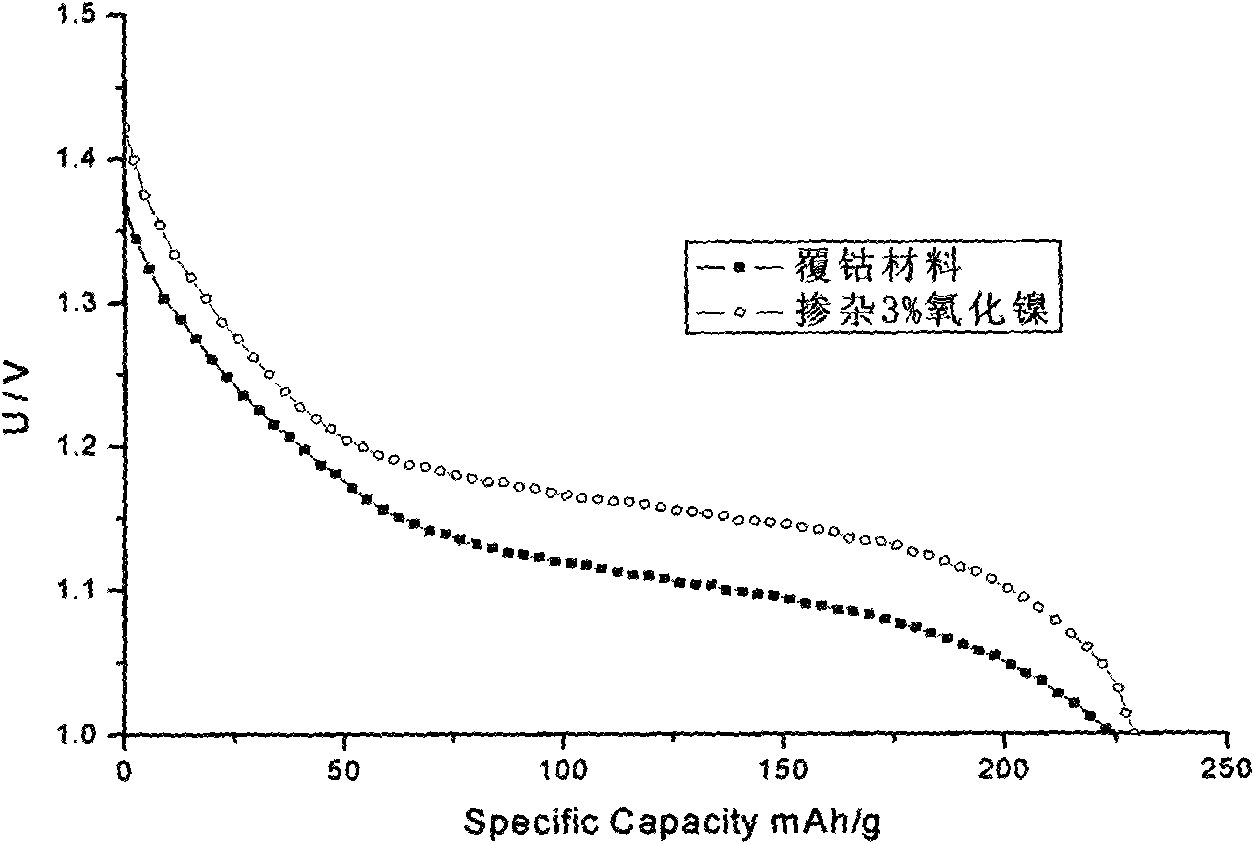

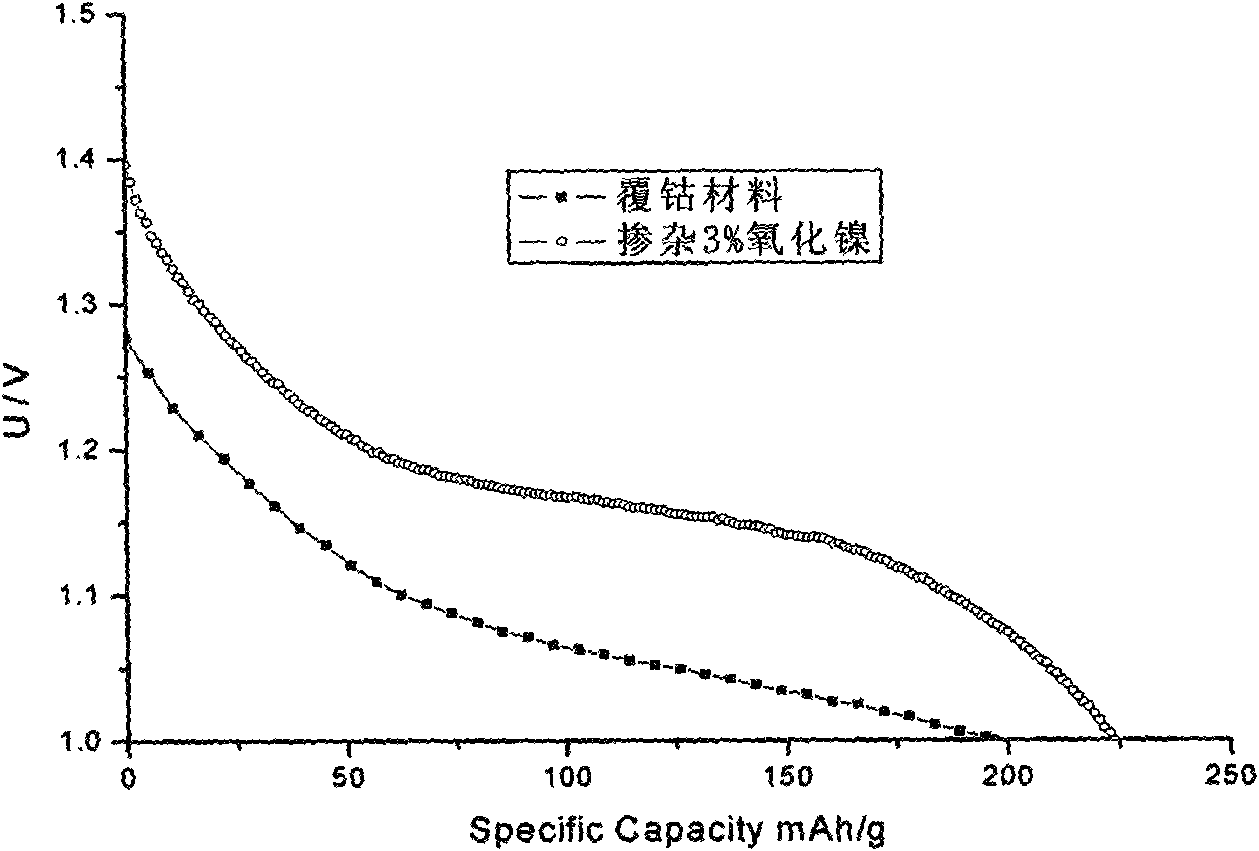

[0022] with 3% Ni 0.833 Al 0.125 mn 0.042 The preparation and performance testing of nickelous composite cathode material of O are taken as an example, and the present invention is described in detail.

[0023] Contains 3% Ni 0.833 Al 0.125 mn 0.042 The preparation of the nickelous composite positive electrode material of O:

[0024] 1. Raw material preparation. Mix Triton X-100 and n-butanol in a mass ratio of 3:2, dissolve in 5 times the volume of cyclohexane, stir to make it transparent, and use it as an emulsifier; prepare NiSO 4 (1mol / L), Al 2 (SO 4 ) 3 (0.15mol / L) and MnSO 4 (0.05%) solution, mix the three in equal volume and add 1% emulsifier, fully stir to obtain salt-containing microemulsion A; prepare NaOH (2mol / L) and ammonia water (0.25mol / L) solution, mix the two Volume mixing and adding 1% emulsifier, fully stirred to obtain alkali-containing microemulsion B.

[0025] 2. Move solution A to the reaction kettle, blow nitrogen gas and seal it, heat to 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com