Method and device for separating carbon dioxide to improve mass energy of blast furnace gas

A technology of carbon dioxide and blast furnace gas, applied in blast furnaces, blast furnace details, furnaces, etc., to achieve the effects of reducing steam consumption, realizing recycling, and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

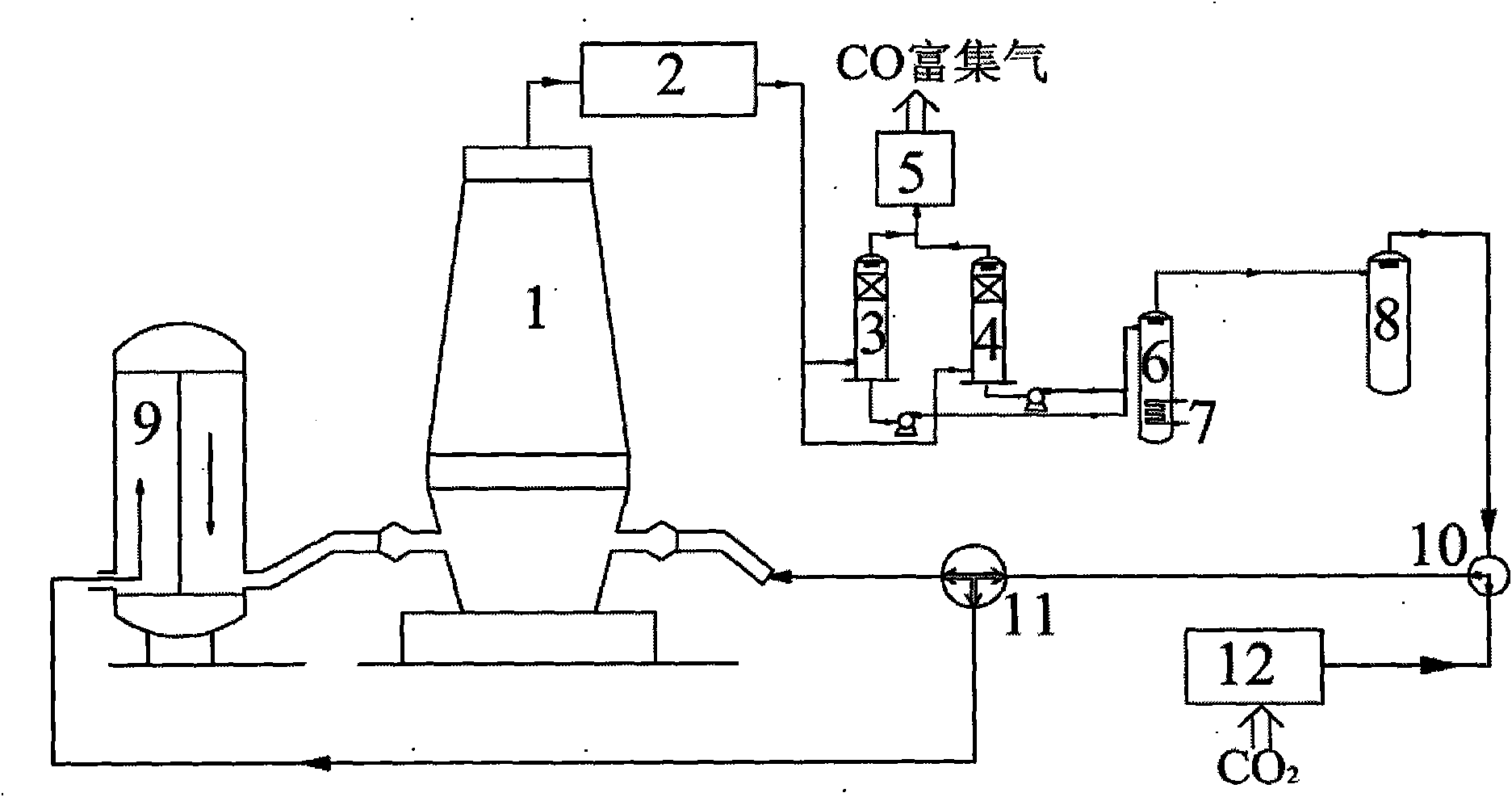

Image

Examples

Embodiment Construction

[0019] 1. To 2000m 3 Blast furnace, separation and recovery of carbon dioxide recycling process from blast furnace gas, recovery of gas 1300-3000m per ton of iron 3 , using the capture device to recover and separate the carbon dioxide as the carrier gas of the blast furnace injection fuel, the gas flow rate is 200 ~ 1000m 3 / min, pressure 0.8~1.5MPa; carbon dioxide is used to replace part of the air into the hot blast stove, and the flow rate of cold air is 3500~6000m 3 / min.

[0020] 2. To 3200m 3 Blast furnace, separation and recovery of carbon dioxide recycling process from blast furnace gas, recovery of gas 1300-3000m per ton of iron 3 , the recovered and separated carbon dioxide is used as the carrier gas for blast furnace injection fuel, and the gas flow rate is 700-1500m 3 / min, pressure 0.2~1MPa; carbon dioxide is used to replace part of the air into the hot blast stove, and the flow rate of cold air is 5000~9000m 3 / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com