Two-stage roasting mineral smelting integrated technique of laterite

A technology of laterite ore and nickel laterite, which is applied in the direction of wet separation, solid separation, chemical instruments and methods, etc., can solve the problems that cannot completely solve the problem of ring formation of materials, and the production situation is not very continuous and stable, so as to be easy to promote , low cost and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

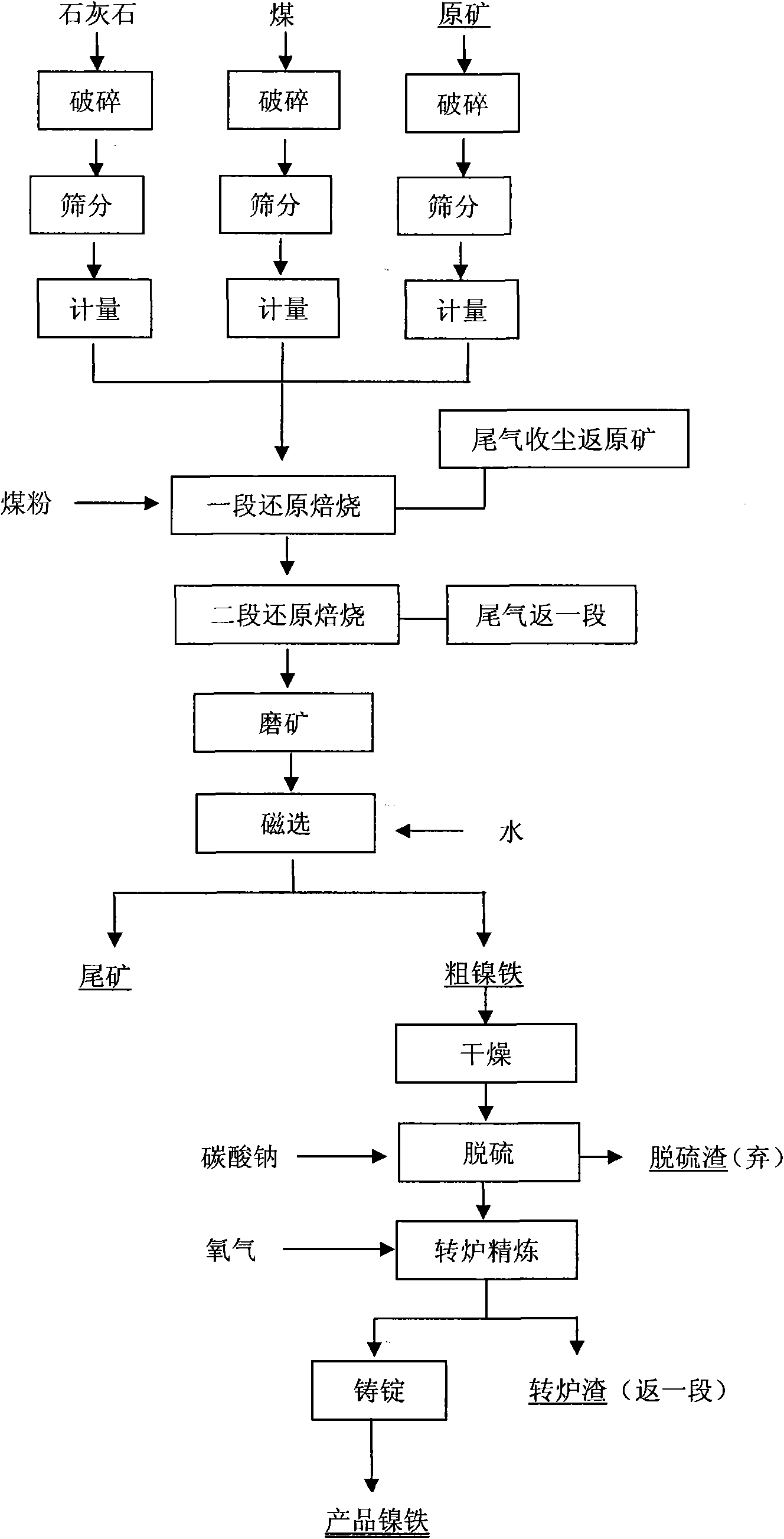

Image

Examples

Embodiment 1

[0030] a. Crush laterite, fluorite and coal to -3mm;

[0031] b. Add 5% coal powder and 5% fluorite powder according to the weight percentage of laterite ore and mix evenly;

[0032] c. Send it into the rotary kiln, control the roasting temperature in the high temperature zone to 1100°C, and the roasting time in the high temperature zone for 30 minutes, and control the material not to soften so that the rotary kiln does not form rings;

[0033] d. After exiting the kiln, the calcined sand enters the intermediate frequency heating device for two-stage roasting, so that the nickel and cobalt in the material are fully reduced, and the iron is partially reduced. The temperature is controlled at 1300°C to soften the material and flow out;

[0034] e. After the material is quenched in the water quenching tank, it is taken out and ground to a particle size of -200 mesh and 80%;

[0035] f, select concentrate ore under the magnetic field intensity of 2000 Oersted with magnetic separa...

Embodiment 2

[0038] a. Crush laterite, calcium oxide and coking coal powder to -2mm;

[0039] b. Add 5% pulverized coal and 10% calcium oxide according to the weight percentage of laterite ore, and then use a disc granulator to make pellets with a diameter of 10-15mm;

[0040] c. Send it into a rotary kiln, control the roasting temperature in the high temperature zone to 1250°C, and the roasting time in the high temperature zone for 60 minutes;

[0041] d. After leaving the kiln, the calcined sand enters the intermediate frequency heating device for two-stage roasting, so that the nickel and cobalt in the material are fully reduced, and the iron is partially reduced. The temperature is controlled at 1400 ° C to soften the material and flow out;

[0042] e. After the material is quenched in the water quenching tank, it is pulled out and then coarsely ground to -5mm, and the metal particles are selected by jigging to enter step g, and the tailings are finely ground to a particle size of -200...

Embodiment 3

[0046] a. Crush laterite, limestone, fluorite and oil shale to -3mm;

[0047] b. Add 5% oil shale, 5% limestone and 2.5% fluorite powder according to the weight percentage of laterite ore and mix them evenly, and then use a pair of roller pressing ball machines to make pellets with a diameter of 10-15mm;

[0048] c. Send it into the rotary kiln, control the roasting temperature in the high temperature zone to 1350°C, and the roasting time in the high temperature zone is 30min;

[0049] d. After leaving the kiln, the calcined sand enters the submerged arc furnace for two-stage roasting, so that the nickel and cobalt in the material are fully reduced, and the iron is partially reduced. After the material is softened by controlling the temperature at 1450°C, the calcined sand is released through the blanking flap;

[0050] e. After the material is quenched in the water quenching tank, it is taken out and ground to a particle size of -200 mesh 75%;

[0051] f, select concentrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com