Method for vertical double-sided double-arc plasma symmetry welding

A double-sided double-arc, symmetrical welding technology, applied in the direction of plasma welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of increasing equipment complexity, serious weld seam overburning, workpiece deformation, etc., to eliminate incomplete penetration Defects, stable arc combustion, and the effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

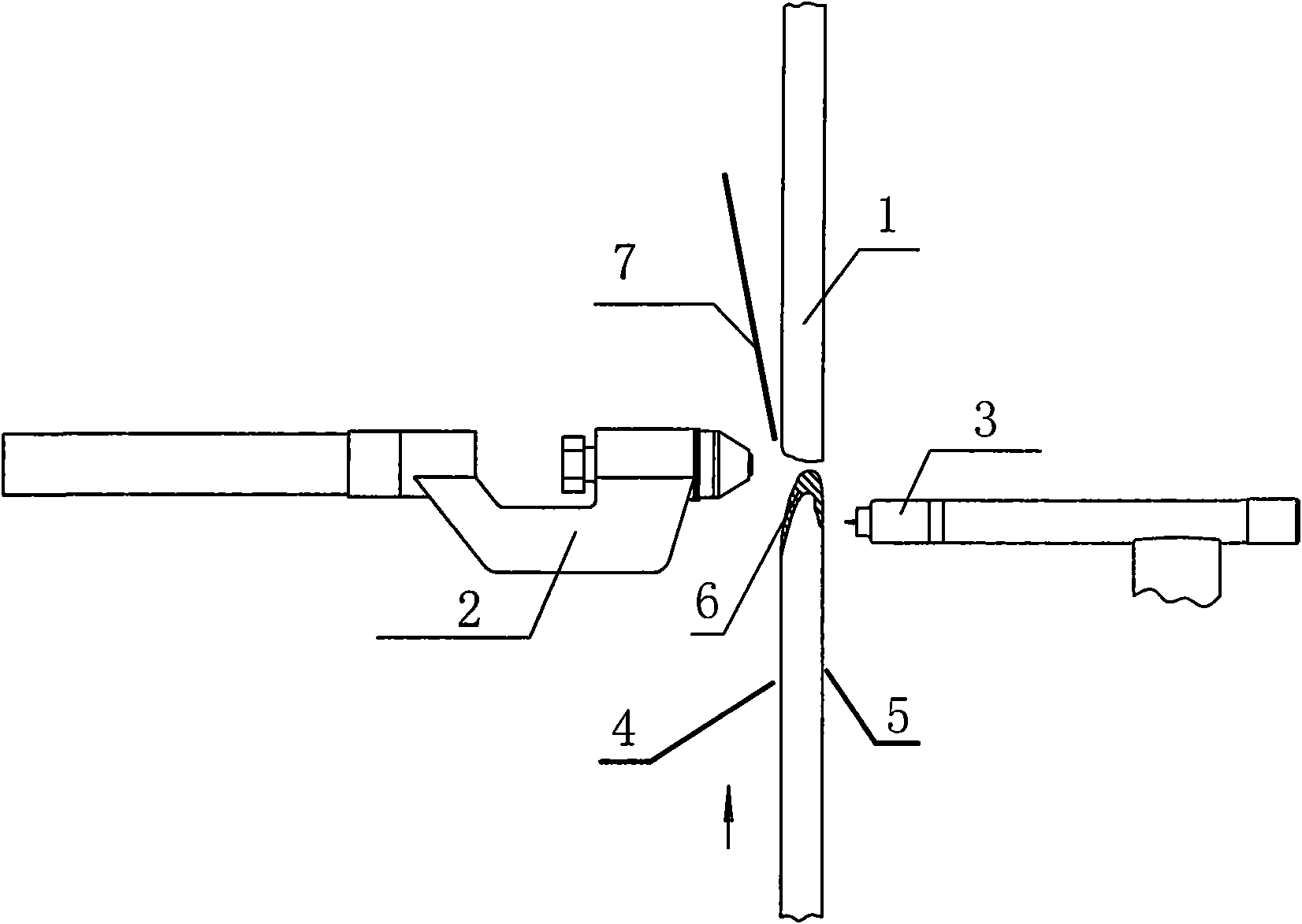

[0028] like figure 1 As shown, the vertical double-sided double-arc plasma symmetrical welding method provided in this embodiment is specifically:

[0029] Place the workpiece 1 vertically along the direction of the welding seam, and set welding torches horizontally on both sides of the front and back of the workpiece respectively. The welding torches on both sides move along the direction of the welding seam at the same speed, and the front side of the workpiece 4 is a VPPAW welding torch. 2. The reverse side of the workpiece 5 is a melting inert gas arc welding (TIG) welding torch or a non-melting inert gas arc welding (MIG) welding torch 3, a melting inert gas arc welding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com