Method for preparing high-voltage diac

A bidirectional trigger and diode technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low reliability of diodes, high requirements for manufacturing conditions, and high production costs, so as to enhance anti-ablation ability and reduce Production cost, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

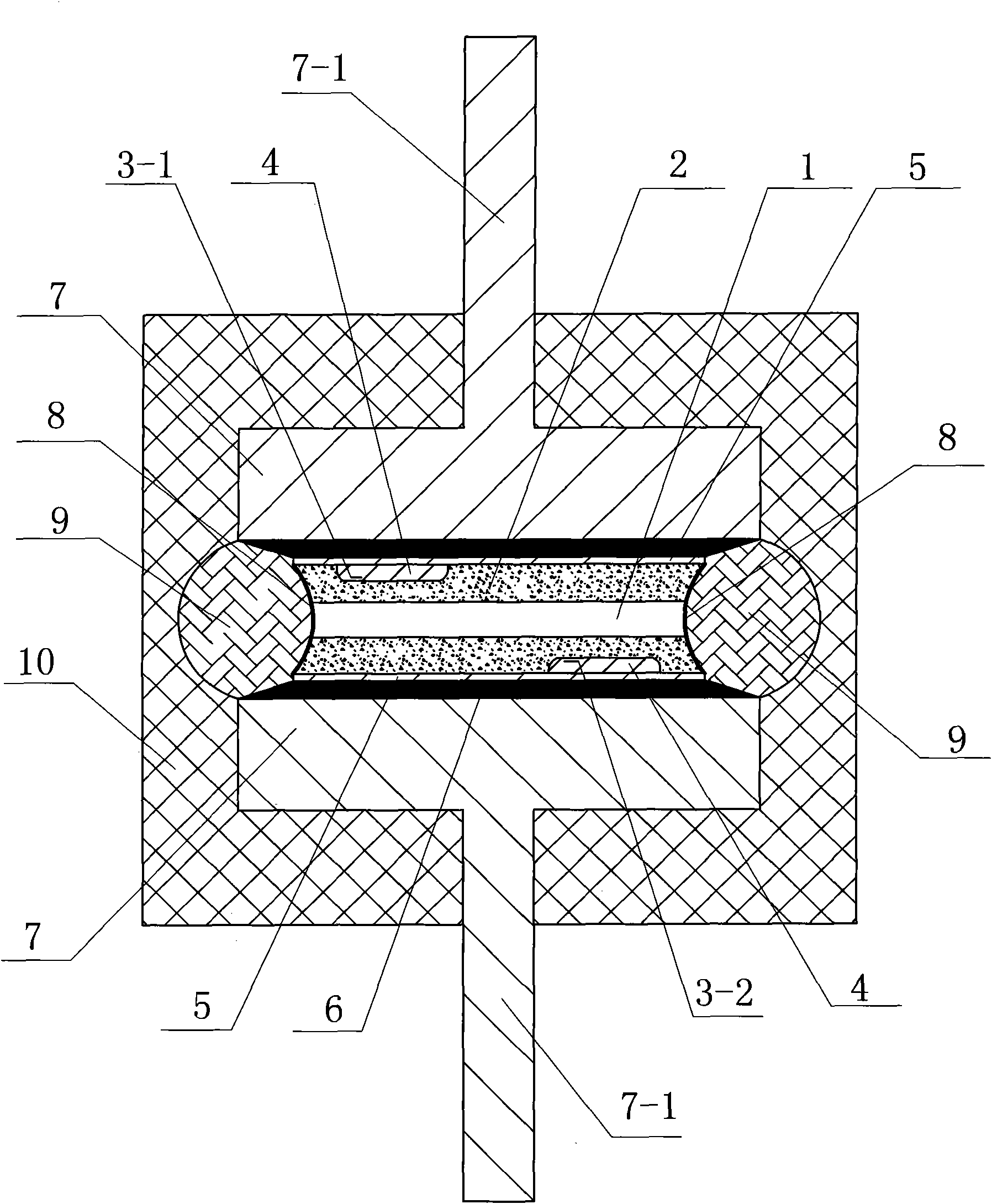

Image

Examples

Embodiment

[0044] Example: Making a high-voltage bidirectional trigger diode

[0045] (1) Prepare raw materials:

[0046] ①Preparation of silicon wafers: Cut the purchased N-type single crystal rods into circular shapes as raw silicon wafers, with a resistivity of ρ=4±1Ω.cm and a thickness of 200±10μm;

[0047] ② Prepare the etching solution used in the chemical polishing step: mix evenly according to the volume ratio of hydrofluoric acid, glacial acetic acid and nitric acid 1:1:2:27;

[0048]3. prepare the rinsing solution used in the nickel plating and alloying steps: mix evenly in the proportion of hydrofluoric acid: deionized water=1:15;

[0049] ④ Prepare the nickel plating solution A used in the nickel plating and alloying steps: nickel chloride: ammonium chloride: diammonium hydrogen citrate: sodium hypophosphite: deionized water = 30g: 50g: 65g: 10g: 1000ml than mixing evenly;

[0050] ⑤ Prepare the mixed acid solution used in the pickling step: mix evenly according to the vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com