Eccentric shaft and manufacturing method thereof

A manufacturing method and eccentric shaft technology, which are applied in the manufacturing process of eccentric shafts, eccentric shafts, and mechanical devices, and can solve the problems affecting the comprehensive mechanical properties of parts, large energy consumption, and large gaps in the performance of parts between the center and the surface. , to achieve the effect of reducing product deformation and cracking, reducing energy consumption and environmental pollution, and reducing the effect of cross-sectional size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The material for the eccentric shaft in the present invention is: 38MnVS6 non-quenched and tempered steel. By controlling the forging and cooling process directly worth the eccentric shaft.

[0023] Rolled rods made of 38MnVS6 non-quenched and tempered steel, with a diameter of φ180mm. Heating to 1150-1200°C.

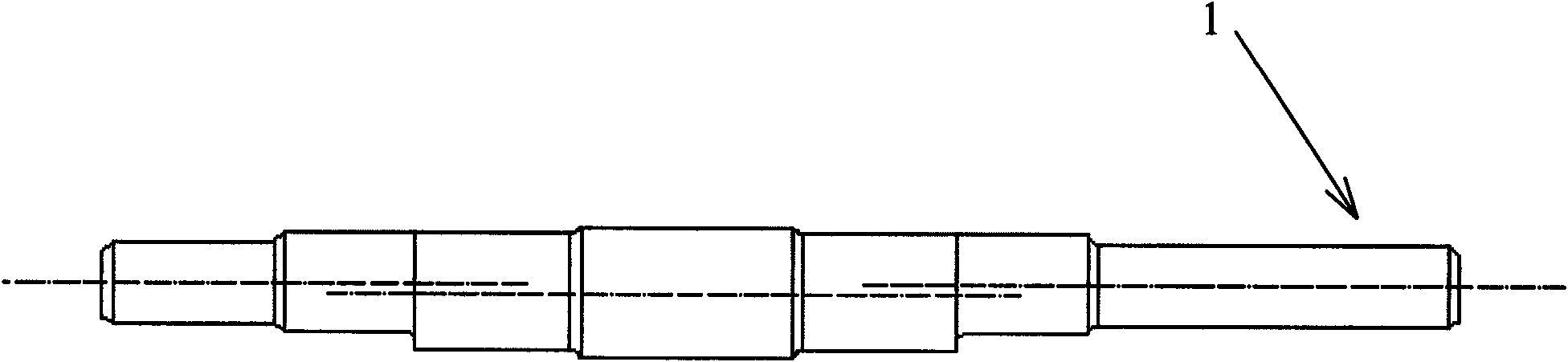

[0024] Forging after heating and heat preservation (see the schematic diagram of the eccentric shaft figure 2 shown), the forging process adopts one-fire forging, and the two ends of the eccentric shaft are forged with multi-pass low final forging temperature, and the final forging temperature is 800-850°C.

[0025] After forging, the single-piece suspension is air-cooled and cooled by air-cooling.

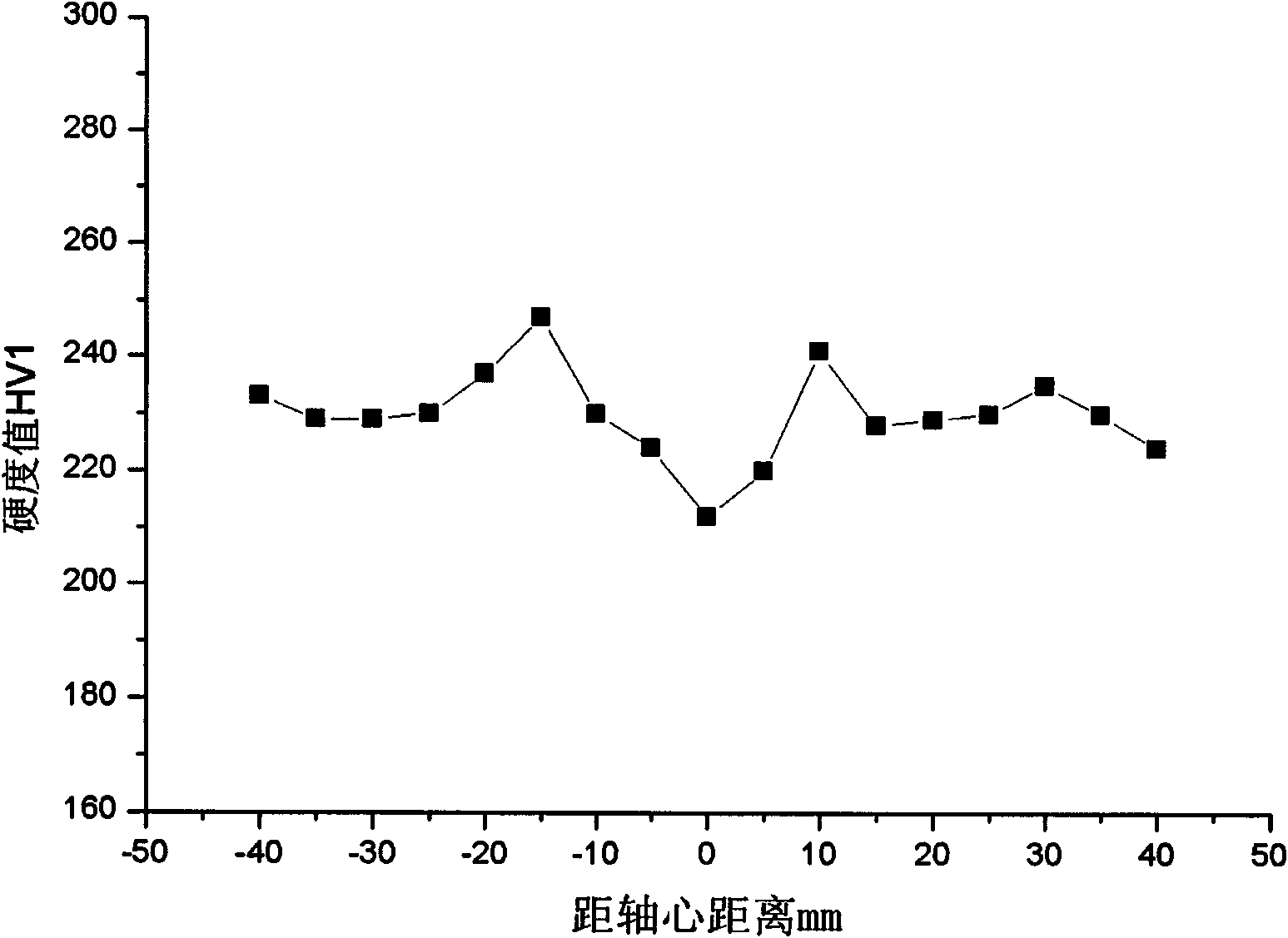

[0026] The variable process parameters and mechanical performance test results of each embodiment and the performance of the eccentric shaft of the original quenched and tempered process are shown in Tables 1 and 2. The cross-sectional hardness distribution curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com