Scintillating glass and preparation method thereof

A technology of scintillating glass and glass, which is applied in the field of scintillator materials and its preparation, can solve the problems affecting the ultraviolet and visible transmittance of glass, affect the optical uniformity of glass, and cannot use platinum, etc., and achieve good ultraviolet transmittance and glass Strong forming ability and easy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Formulation design:

[0027] Phosphate system is used. The components are designed as follows:

[0028] The glass composition (mol%) of table 1 embodiment 1

[0029] P 2 o 5

SrO

SnO 2

75

25

2

[0030] Batch preparation:

[0031] High-purity (99.9%) ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), strontium carbonate (SrCO 3 ) and tin oxide for the introduction of P 2 o 5 , SrO and SnO 2 The raw materials, according to the composition shown in Table 1, formula calculation and batch preparation. The batch preparation method is the same as the conventional glass batch preparation method. The ingredients need to be mixed thoroughly.

[0032] Glass melting:

[0033] Put the uniformly mixed batch materials into a platinum crucible, and melt the glass in an electric furnace. The melting atmosphere is air, the melting temperature is 1250°C, and the melting time is 2 hours. During the heat preservation period, the g...

Embodiment 2-4

[0043] In each of the following examples, the preparation method of the glass is the same as in Example 1, and the different glass compositions, densities and fluorescent performance test results used are listed in Table 3 and Table 4 respectively.

[0044] The glass composition (mol%) of table 3 embodiment 2-4

[0045] serial number

P 2 o 5

SrO

BaO

CaO

SnO 2

2

75

25

5

3

60

40

2

4

75

25

2

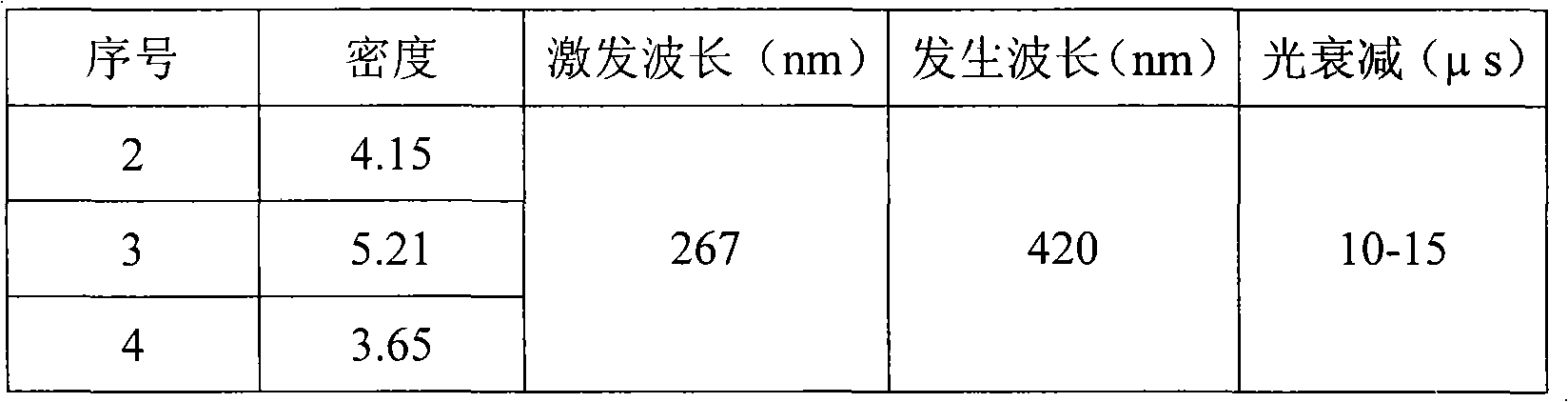

[0046] Fluorescent properties and density test results of glass in table 4 embodiment 2-4

[0047]

Embodiment 5

[0049] In the following examples, the preparation method of the glass is the same as in Example 1, and the test results of different glass compositions, densities and fluorescent properties are listed in Table 5 and Table 6 respectively.

[0050] Formulation design:

[0051] A germanate system is used. The components are designed as follows:

[0052] The glass composition (mol%) of table 5 embodiment 5

[0053] GeO 2

SrO

SnO 2

70

30

5

[0054] Batch preparation:

[0055] High-purity (99.9%) germanium oxide (GeO 2 ), strontium carbonate (SrCO 3 ) and tin oxide (SnO2 ) to introduce P 2 o 5 , SrO and SnO 2 The raw materials, according to the composition shown in Table 1, formula calculation and batch preparation. The batch preparation method is the same as the conventional glass batch preparation method. The ingredients need to be mixed thoroughly.

[0056] Fluorescence performance and density test result of table 6 embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com