Synthesis method of P(AM-DMDAAC)

A technology of AM-DMDAAC and synthesis method, applied in the field of P synthesis, can solve problems such as safety threats to workshop workers, difficulties in industrial production and operation, and reduced solubility of flocculants, and achieves easy popularization and use, good synthesis effect, and product conversion. The effect of increasing rate and intrinsic viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] P(AM -DMDAAC), poly(acrylamide-dimethyldiallylammonium chloride). The jars used for the reaction were made of quartz and glass to carry out parallel experiments to consider the influence of quartz and glass on the conversion rate and intrinsic viscosity. The specific steps are:

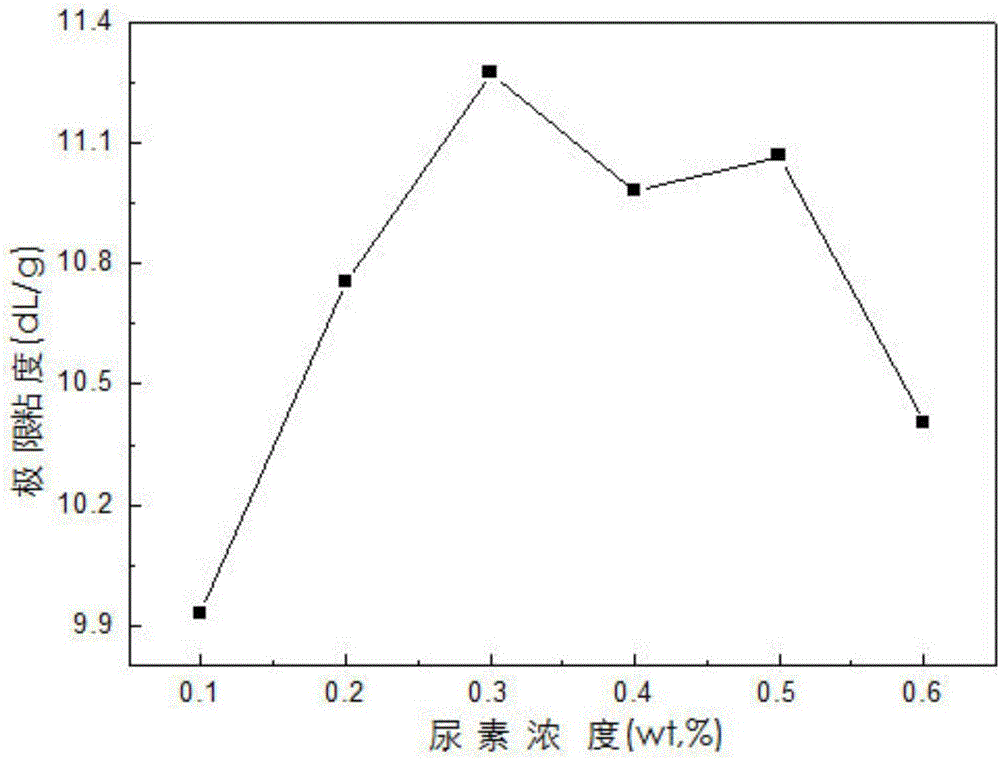

[0039] 1) Add AM monomer and distilled water into the jar, then add PAAS, DMDAAC monomer, EDTA and urea in sequence (add 60mg urea to 20ml distilled water to obtain a urea solution with a concentration of 3‰), then stir until completely dissolved , forming a mixed solution.

[0040] 2) Use hydrochloric acid and sodium hydroxide to adjust the pH value of the mixed solution to 4, and then pass nitrogen to drive oxygen; then add an azo initiator in a nitrogen atmosphere, and continue to pass nitrogen for 10 minutes, and then seal the jar to form a seal reaction system.

[0041] 3) Put the sealed reaction system under ultraviolet light with a wavelength of 253.7nm and a power of 24W to irradiate...

Embodiment 2

[0049] P(AM -DMDAAC), poly(acrylamide-dimethyldiallylammonium chloride). Its reaction condition is identical with embodiment one, and difference only is that two groups of experimental conditions are respectively one group uses high pressure ultraviolet light (wavelength 365nm, power 500W), glass jar, and another group uses low pressure ultraviolet light (wavelength 257.3nm , power 24W) and quartz jars, and in this way, consider the influence of high and low pressure ultraviolet light on the system temperature and the conversion rate of high and low pressure ultraviolet light illumination time.

[0050] Depend on Figure 7 It can be seen that with the increase of the reaction time, the temperature of the reaction system increases significantly, and the temperature change of the system caused by high-pressure ultraviolet light is more severe. When the reaction time reaches 60 minutes, the temperature of the system under the two triggers tends to be stable, indicating that the...

Embodiment 3

[0053] P(AM -DMDAAC), poly(acrylamide-dimethyldiallylammonium chloride). Its reaction condition is identical with embodiment two, and difference only is that two groups of experimental conditions are respectively a group of high pressure ultraviolet light (wavelength 365nm, power 500W), glass jar, and another group uses low pressure ultraviolet light (wavelength 257.3nm , power 24W) and quartz jars, and in this way, consider the influence of high and low pressure ultraviolet light irradiation time on intrinsic viscosity and conversion rate.

[0054] Depend on Figure 9 It can be seen that the conversion rate using high-pressure ultraviolet light and low-pressure ultraviolet light increases with time, and when the reaction time reaches 60 minutes, the conversion rate has reached 98%, 97.6%. Afterwards, it hardly changes with the increase of reaction time. The conversion rates of using both high-pressure UV light and low-pressure UV light at the same time are approximately th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com