Method for preparing nuclear shell type high magnetic content super paramagnetic microsphere

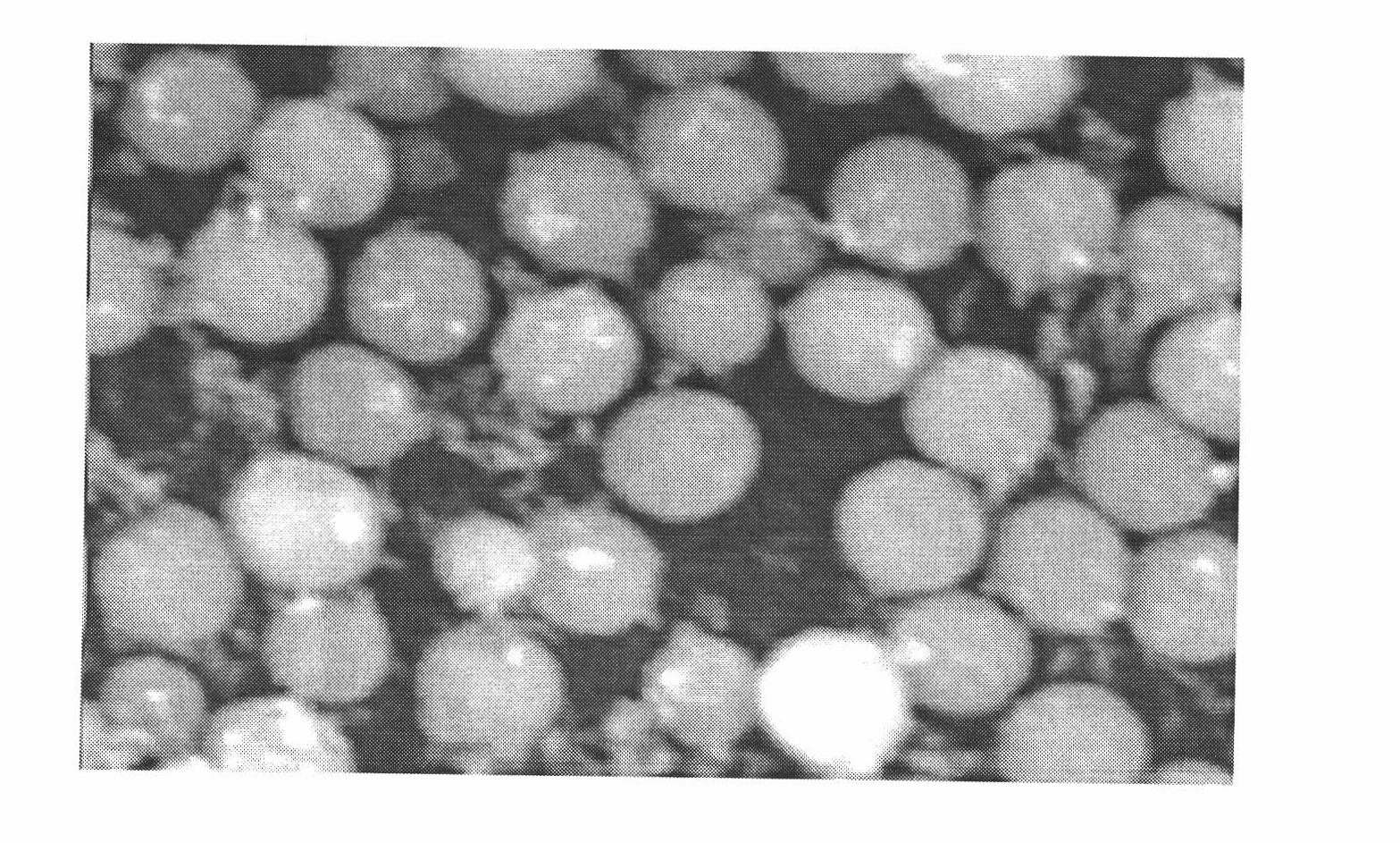

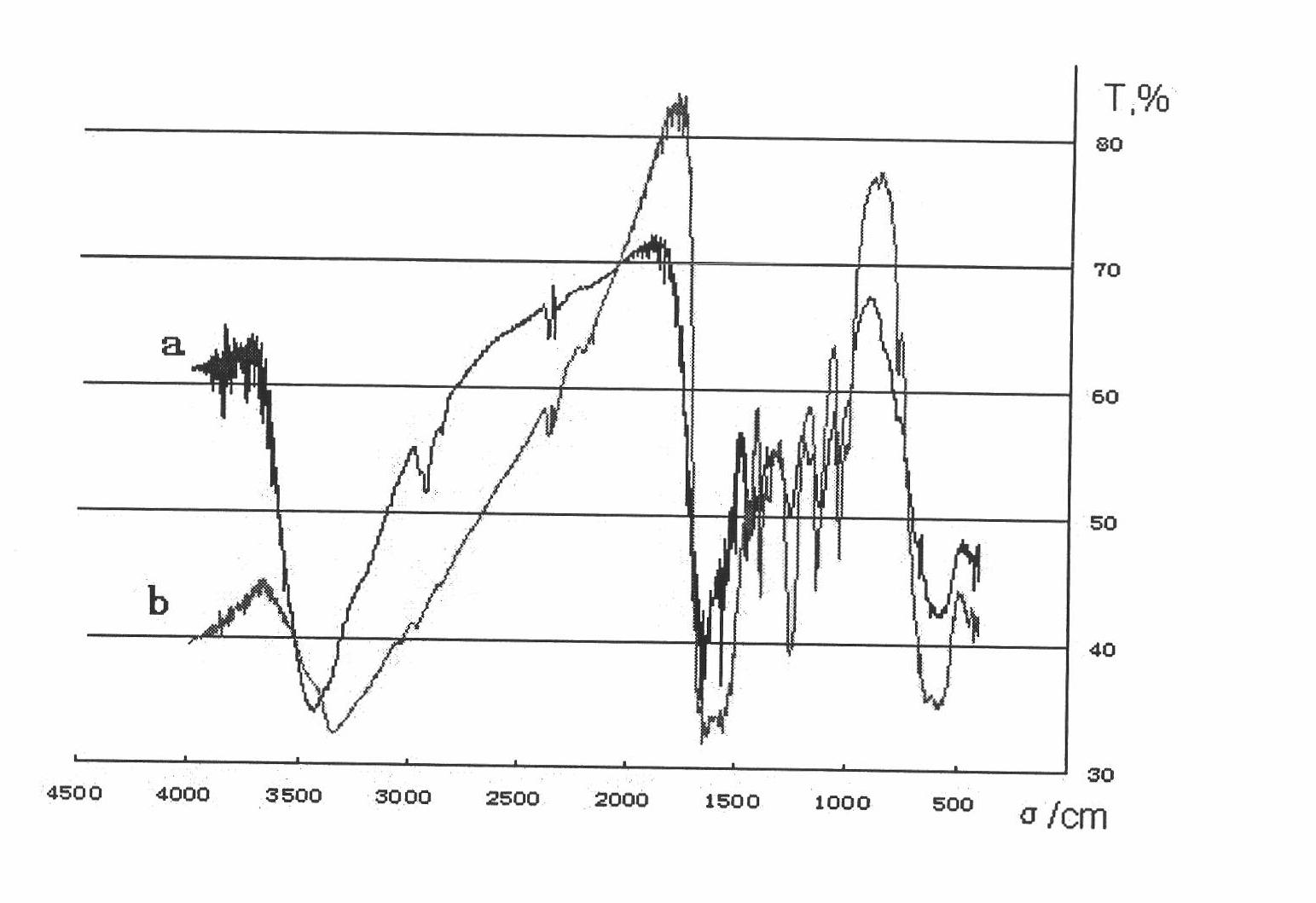

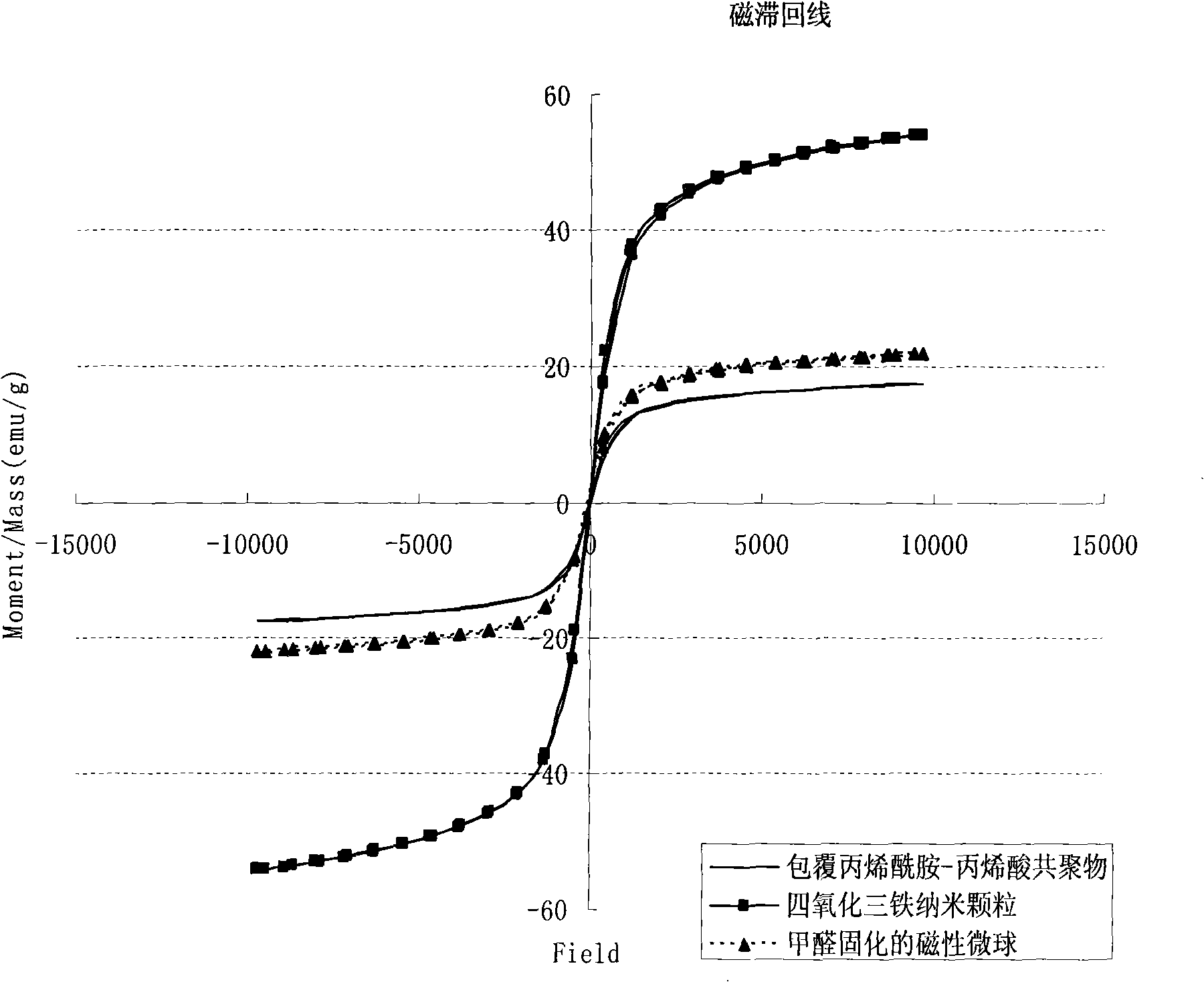

A superparamagnetic, core-shell technology, applied in the direction of magnetism of inorganic materials, to achieve good commercial application prospects, uniform particle size, and less production process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] Preparation of monoclonal antibody magnetic immune microspheres:

[0038] Prepare ferrofluid:

[0039] Add nitric acid solution, 0.2g / ml urea solution and ultrapure water in sequence to the ferric oxide powder, and mix them evenly to form a mixture; the magnetic powder, acid solution, urea solution and ultrapure water in the mixture The mass ratio of the mixture is 0.3:1:1.8:16.5; the mixture is ultrasonically dispersed in a water bath at 70°C for 20 minutes, and then placed at 20°C for 7 days to sink and purify to remove impurities;

[0040] Prepare magnetic microsphere suspension:

[0041] Take the purified magnetic fluid, adjust the pH value to 5.5 with sodium hydroxide solution, add formaldehyde solution with a volume percentage concentration of 37% therein, and the volume ratio of the magnetic fluid and the formaldehyde solution is 40:1; then place the mixed solution Stand still for 30 minutes in a water bath at 50°C. After observing a large number of microsphere...

example 2

[0049] Prepare ferrofluid:

[0050] In the iron nitride powder, sequentially add hydrochloric acid solution, 0.01g / ml urea solution and ultrapure water with a mass percentage concentration of 1%, and mix uniformly to form a mixture; the magnetic powder, acid solution, urea solution and ultrapure water in the mixture The mass ratio is 0.3:1:1.8:16.5; the mixture is ultrasonically dispersed in a water bath at 70°C for 20 minutes, and then placed at 20°C for 7 days, and purified to remove impurities;

[0051] Prepare magnetic microsphere suspension:

[0052] Take the purified magnetic fluid, adjust the pH value to 7.0 with potassium hydroxide solution, add a formaldehyde solution with a concentration of 37% by volume, and the volume ratio of the magnetic fluid to the formaldehyde solution is 30:1; In a water bath environment at 10°C, let it stand for 40 minutes. After observing a large number of microspheres with a particle size of 1um under a microscope, disperse the product in...

example 3

[0056] Prepare ferrofluid:

[0057] Add the perchloric acid solution, 0.5g / ml urea solution and ultrapure water in sequence to the ferric oxide powder, and mix them evenly to form a mixture; the magnetic powder, acid solution, urea solution and ultrapure water in the mixture The mass ratio of pure water is 0.3:1:1.8:16.5; the mixture is ultrasonically dispersed in a 70°C water bath for 20 minutes, and then placed at 20°C for 7 days to purify and remove impurities;

[0058] Prepare magnetic microsphere suspension:

[0059] Take the purified magnetic fluid, adjust the pH value to 4.0 with ammonia water, add a formaldehyde solution with a volume percentage concentration of 37% to it, and the volume ratio of the magnetic fluid to the formaldehyde solution is 45:1; then place the mixed solution at 70°C In a water bath environment, stand still for 5 minutes. After a large number of microspheres with a particle size of 1um are observed under a microscope, the product is dispersed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com