Preparation method of Chinese wolfberry powder

A production method and technology of wolfberry powder, which are applied in food preparation, food shaping, food preservation, etc., can solve problems such as the influence of product sensory effect, high processing temperature, and the stability of product quality, so as to broaden the comprehensive development path and speed up Transformation process, the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

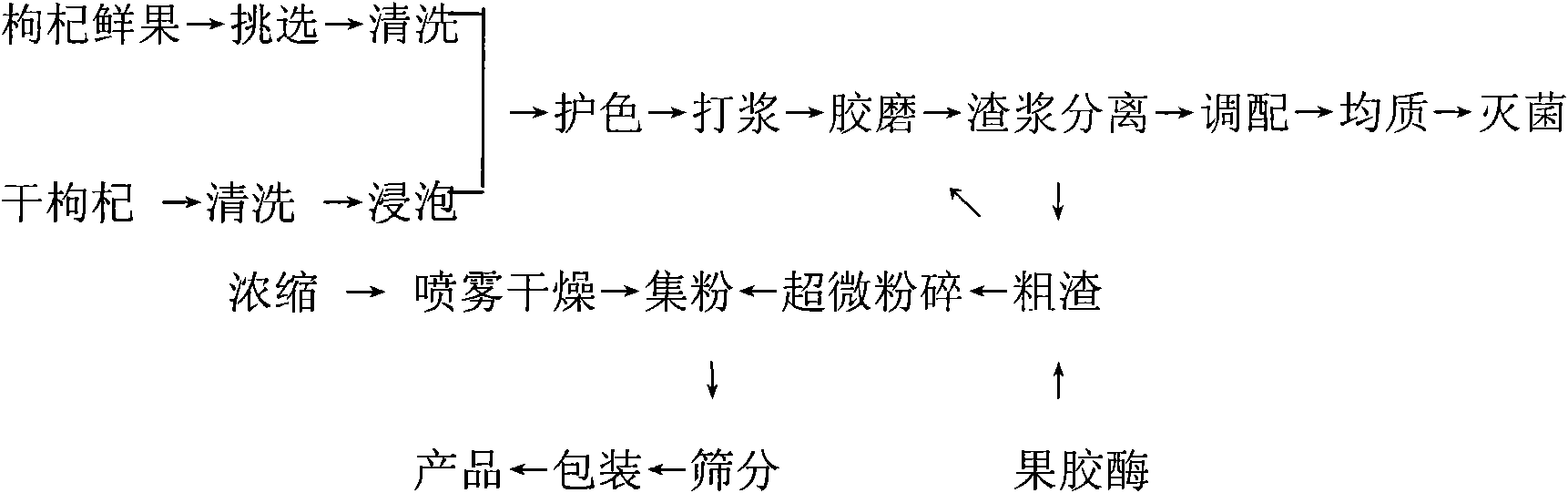

[0022] A preparation method of wolfberry powder, using fresh or dried wolfberry as main raw material, after selection, cleaning or soaking, color protection, beating, rubber milling, secondary treatment, deployment, homogenization, sterilization, concentration, dry spray drying , powder collection, screening, packaging, and product warehousing processes to obtain a wolfberry powder product.

[0023] Specific implementation steps: select fresh Lycium barbarum fruit with thick quality, large fruit size and ripeness, and pick out leaves, sepals, fruiting branches, insect fruit, rotten fruit and earth and rocks. Weighed net weight 100kg. Add color-protecting solution directly for crushing and beating, add 100kg of water according to the ratio of material to liquid 1:1, and add 0.2kg of color-protecting agent sodium sulfite at the same time, beat into a coarse pulp with a fineness of 1mm. The material passed through the beater enters the colloid mill for further refinement, and th...

Embodiment 2

[0025]The dried fruit of wolfberry should remove impurities such as mildew, brown stain, fruit eaten by insects, sand, gravel, soil clods, orange stalks, etc., and the net weight is 100kg. Add 300kg of hot water to soak the wolfberry after removing impurities for 30min at 60°C. Add 0.4kg iso-Vc sodium and 0.4kg citric acid when soaking. The soaked wolfberry is beaten into a coarse pulp with a beater, and the fineness is 1mm. The material passed through the beater enters the colloid mill for further refinement, and the gap between the grinding discs is adjusted to 22 μm. The slurry that has passed through the colloid mill is separated and filtered with 80 mesh pulp residue. Then, pectinase treatment is carried out on the coarse slag. The specific method is to add 120mg / kg enzyme preparation and keep it warm at 45°C for 90 minutes to decompose part of the pectin, and then return to the colloid mill for further processing. Finally, the coarse slag that cannot be decomposed is ...

Embodiment 3

[0027] The process conditions were changed to: 300kg of dry wolfberry pulp separated from slag pulp was treated with pectinase. The specific method was to add 120mg / kg of enzyme preparation and keep it warm at 50°C for 120min to decompose part of the pectin, and then return to the colloid mill for further processing. processing. Finally, the coarse slag that cannot be decomposed is treated by ultrafine pulverization, and the obtained fine powder is recycled to the powder collection bin together. The slurry is pumped into a jacketed pot with a stirrer, 36kg of isomaltooligosaccharide and 54kg of resistant starch are added, and 15kg of trehalose is added at the same time, and stirred evenly. Vacuum cryogenic concentration may not be carried out. Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 12.5MPa. Air inlet temperature: 170°C, exhaust air temperature: 70°C, 43kg of finished product is obtained after drying, and the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com