Method for separating tertiary butanol and water

A technology of tert-butanol and separator, applied in the field of separating tert-butanol-water, can solve the problems of low product quality and yield, high production cost, etc., and achieve the effects of convenient operation, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

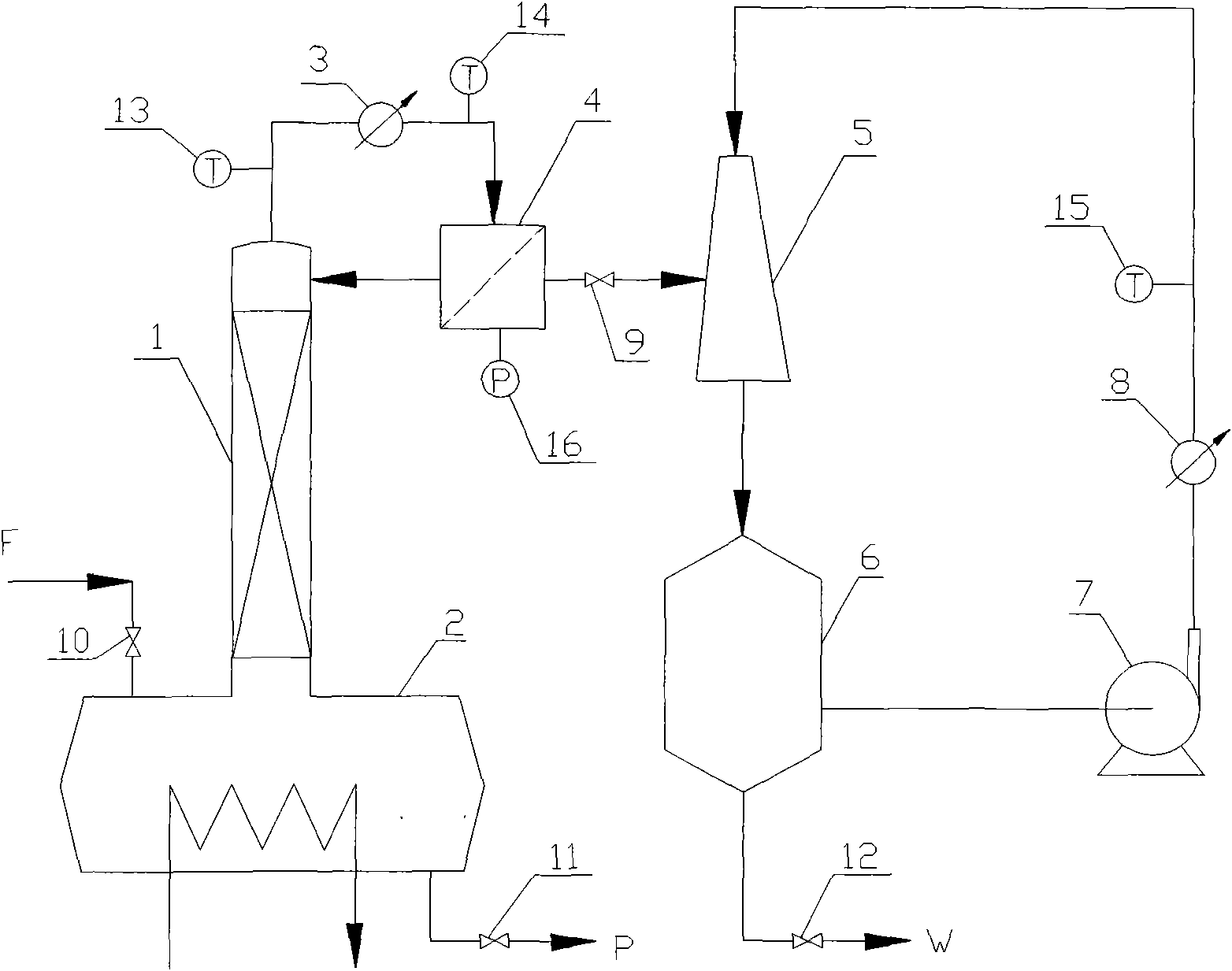

[0021] Embodiment 1: as figure 1 The diagram of the device is shown. Put the tert-butanol-water solution F600ml containing 80% (wt %) tert-butanol into the batch distillation column tower kettle 2, check whether the joints are well sealed, valves 9-10 are closed, and feed to the top condenser 3. After feeding the cooling water, turn on the heating power supply to heat the reboiler, and operate the total reflux after there is reflux at the top of the tower, and control the temperature of the reflux liquid at 70-75°C.

[0022] Start the circulating pump 7 to keep the circulating water in a circulating state, and adjust the cooling water flow of the cooler (8), control the circulating water temperature to be 30-35°C, adjust the flow of the circulating pump (7), and keep the absolute pressure at 2500~ 5000Pa; after the azeotrope of tert-butanol-water gathers at the top of the tower, the cooler (8) cools the tert-butanol water to a liquid at 70-75°C.

[0023] When the gas phase t...

Embodiment 2

[0026] Example 2 as figure 1 The diagram of the device is shown. The tert-butanol-water solution F600ml that will contain 88% (wt %) tert-butanol is dropped in the batch rectification tower tower still 2, checks whether each joint is sealed well, and valve 9-10 is closed state,

[0027] After passing cooling water into the tower top condenser 3, turn on the heating power supply to heat the reboiler, and operate the total reflux after there is reflux at the top of the tower, and control the temperature of the reflux liquid to be 70-75°C.

[0028] Start the circulating pump 7 to keep the circulating water in a circulating state, and adjust the cooling water flow of the cooler 8 to control the temperature of the circulating water at 30-35°C, and adjust the flow of the circulating pump 7 to keep the absolute pressure at 2500-5000Pa; After the alcohol-water azeotrope gathers at the top of the tower, the cooler (8) cools the tert-butanol water to a liquid at 70-75°C.

[0029] When...

Embodiment 3

[0032] Example 3 as figure 1 The diagram of the device is shown. The tert-butanol-water solution (F) 600ml that will contain 92% (wt %) tert-butanol is put into batch rectification column tower still 2, checks whether each joint is sealed well, and valve 9-10 is closed state, to tower After the cooling water is fed into the top condenser 3, the heating power is turned on to heat the reboiler, and the total reflux operation is performed after there is reflux at the top of the tower, and the temperature of the reflux liquid is controlled to be 70-75°C.

[0033] Start the circulating pump 7 to keep the circulating water in a circulating state, and adjust the cooling water flow of the cooler 8 to control the temperature of the circulating water at 30-35°C, and adjust the flow of the circulating pump 7 to keep the absolute pressure at 2500-5000Pa; After the alcohol-water azeotrope gathers at the top of the tower, the cooler 8 cools the tert-butanol water to a liquid at 70-75°C.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com