Dispersion drag-reduction agent for high-salinity thick oil

A technology of high salinity and drag reducing agent, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as difficulties and achieve good wetting, emulsifying and dispersing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Composition of high salinity heavy oil dispersion drag reducer:

[0026] Component Mass (Kg)

[0027] Unsaturated polyether (industrial grade) 128Kg

[0028] Sodium alkyl sulfonate (industrial grade) 2Kg

[0029] PE-D2 (industrial grade) 13Kg

[0030] Synthesis of unsaturated polyethers:

[0031] 1) In a 1000L synthesis kettle, add 361Kg oleic acid polyoxyethylene ether (industrial grade, anhydrous), then heat to 40°C and melt until uniform;

[0032] 2) Under the protection of nitrogen, slowly add 5.8Kg of chlorosulfonic acid into the synthesis kettle, stir while adding, keep at 40°C, and keep the temperature at 40°C (±2°C) for 1 hour after the addition;

[0033] 3) Raise the temperature of the reactant in the synthesis kettle to 80°C, keep it warm for 1 hour, then make NaOH into an aqueous solution with a mass fraction of 20%, slowly add it into the synthesis kettle at 40°C, stir while adding, until the pH is adjusted to 8 (±0.2).

[0034] Preparation of high sal...

Embodiment 2

[0036] Composition of high salinity heavy oil dispersion drag reducer:

[0037] Component Mass (Kg)

[0038] Unsaturated polyether (industrial grade) 128Kg

[0039] Sodium alkyl sulfonate (industrial grade) 5Kg

[0040] PE-D2 (industrial grade) 10Kg

[0041] Synthesis of unsaturated polyethers:

[0042] 1) In a 1000L synthesis kettle, add 255Kg allyl alcohol polyoxypropylene polyoxyethylene ether (industrial grade, anhydrous, etc.), then heat to 40°C and melt until uniform;

[0043] 2) Under the protection of nitrogen, slowly add 5.8Kg of chlorosulfonic acid into the synthesis kettle, stir while adding, keep at 40°C, and keep the temperature at 40°C (±2°C) for 1 hour after the addition;

[0044] 3) Raise the temperature of the reactant in the synthesis kettle to 80°C, keep it warm for 1.5 hours, then make NaOH into an aqueous solution with a mass fraction of 20%, slowly add it into the synthesis kettle at 40°C, stir while adding, until the pH is adjusted to 8 (±0.2).

[...

Embodiment 3

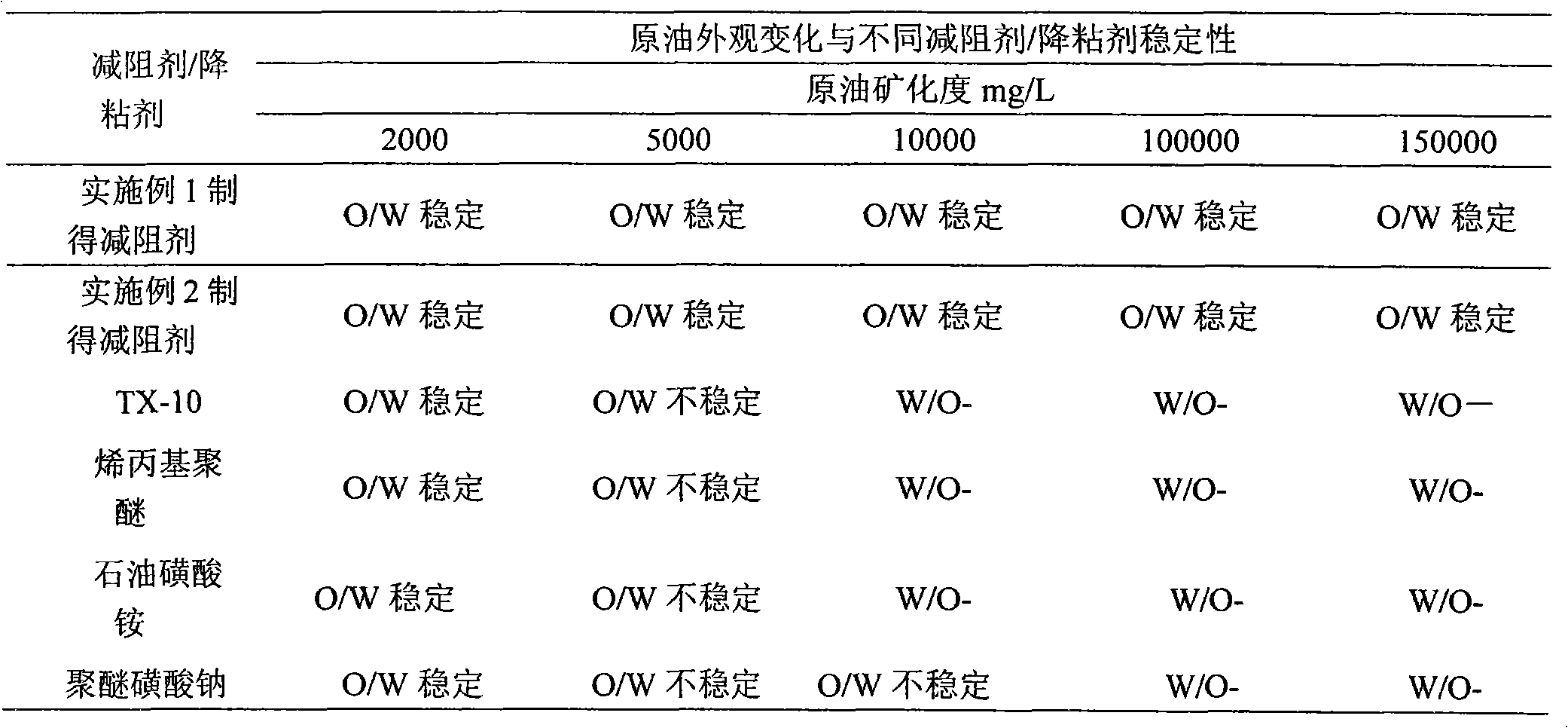

[0047] The salinity resistance test of the high salinity thick oil dispersion drag reducer of the present invention: first make the high salinity thick oil dispersion drag reducer into a 1%-0.1% active aqueous solution, and then add it to the oil with the pump used in the oil field In, the mass ratio of active aqueous solution and oil is 1:3, and the results are shown in Table 1 and Table 2.

[0048] Table 1

[0049] match

party

crude oil mine

degree

mg / L

crude oil

viscosity

mPa.S

temperature

(℃)

oil to water ratio

oil: water

Dosage

(PPm)

doped raw

viscosity

(mPa.S)

lotion type

Stable effect

fruit

match

party

1

200000

mg / L

10000

0

50

3∶1

500

250

O / W

Stablize

match

party

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com